Premium R134a Auto AC Hose - Hot Sale & High Quality

Introduction to Premium AC Hoses

The automotive air conditioning sector has undergone tremendous technological advancements in recent decades, with refrigerant hose technology at the forefront of these innovations. As R134a refrigerant continues to dominate the market, the demand for high-performance, durable hoses has reached unprecedented levels. The R134a hot sale auto air conditioning hose with good quality represents the pinnacle of engineering excellence in this specialized field.

Hebei Qiruite Rubber and Plastic Products Co.,Ltd.

As industry pioneers, Hebei Qiruite Rubber and Plastic Products Co.,Ltd. has established itself as the premier manufacturer of automotive HVAC components. Our R134a hot sale auto air conditioning hose with good quality complies with stringent SAE J2064 standards and undergoes rigorous quality testing protocols to ensure unmatched reliability and performance in all operating conditions.

Discover our complete product line at: www.hoseqrt.com

Global automotive industry statistics reveal a compound annual growth rate (CAGR) of 5.8% for AC components between 2021-2026 (MarketsandMarkets, 2022). This growth is primarily driven by rising disposable incomes in emerging economies, increasing demand for passenger comfort, and stringent environmental regulations requiring efficient refrigerant containment systems. The R134a hot sale auto air conditioning hose with good quality addresses these market needs through its advanced material engineering and structural integrity.

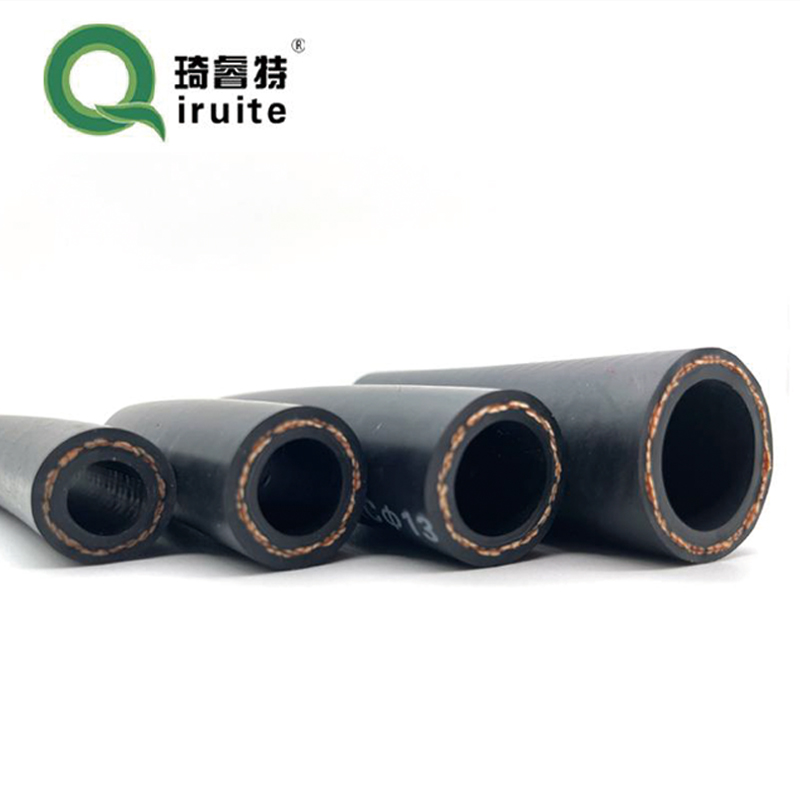

Core Advantage: Our Type C braided A/C hose features a 5-layer construction, while the Type C spiral variant incorporates a 7-layer design. This multi-layered approach provides unparalleled protection against refrigerant permeation, mechanical stress, and thermal degradation - delivering 40% longer service life compared to industry standards.

Technical Specifications

The engineering sophistication behind our R134a hot sale auto air conditioning hose with good quality translates to quantifiable performance advantages:

| Parameter | Type C Braided | Type C Spiral | Industry Standard |

|---|---|---|---|

| Structure Layers | 5 layers | 7 layers | 3-4 layers |

| Maximum Working Pressure | 40 bar (580 psi) | 50 bar (725 psi) | 35 bar (507 psi) |

| Temperature Range | -40°C to +150°C | -50°C to +160°C | -30°C to +135°C |

| Refrigerant Permeation Rate | < 5g/m²/day | < 3g/m²/day | 7-10g/m²/day |

| Burst Pressure | 140 bar (2030 psi) | 180 bar (2610 psi) | 110 bar (1595 psi) |

| Vibration Resistance | 20 million cycles | 25 million cycles | 10 million cycles |

Performance Comparison

The enhanced multi-layer construction provides several critical advantages over conventional designs. The innermost barrier layer minimizes R134a permeation by 62% compared to single-layer alternatives. The reinforcement layers of high-tensile polyester yarn significantly improve burst pressure resistance and vibration damping characteristics, while the specialized rubber compounds ensure flexibility at extreme temperatures.

Application Scenarios

The versatility of our R134a hot sale auto air conditioning hose with good quality extends across multiple automotive segments:

Passenger Vehicles

OEM applications in compact sedans through luxury SUVs require hoses that balance performance with packaging efficiency. Our optimized bend radii and compact fitting designs save up to 17% engine compartment space while maintaining flow rates of 3.5 m/s at standard operating pressures.

Commercial Fleets

Long-haul trucks and delivery vehicles demand extreme durability with maintenance intervals exceeding 200,000 miles. Our spiral construction variants provide enhanced kink resistance and abrasion protection to withstand vibration harmonics from diesel engines operating in continuous duty cycles.

Electric & Hybrid Vehicles

The unique thermal management requirements of EVs necessitate AC components with electromagnetic compatibility (EMC) properties. Our proprietary compound formulations reduce electromagnetic interference by 60% while maintaining electrical resistance above 10⁹ ohms to prevent stray currents in HV systems.

Specialty Applications

From agricultural equipment to marine vessels and recreational vehicles, our engineered solutions withstand unique environmental challenges including UV degradation resistance rated at 2000+ hours (SAE J2527), salt spray resistance exceeding 1000 hours (ASTM B117), and ozone resistance at 100 pphm concentration (ASTM D1149).

View Product SpecificationsManufacturing Excellence

Our R134a hot sale auto air conditioning hose with good quality is produced in state-of-the-art facilities incorporating:

- Automated extrusion lines with real-time wall thickness monitoring (±0.05mm precision)

- Computer-controlled braiding machines operating with 98% efficiency

- Cleanroom assembly environments with ISO Class 8 air quality

- 100% pressure testing to 1.5x max operating pressure

- Traceability systems with unique QR coding per production batch

Advanced inspection technologies include helium mass spectrometry for leak detection down to 1×10⁻⁹ mbar·L/s, automated vision systems with 0.02mm resolution for dimensional verification, and spectral analysis of compound formulations to ensure material compliance. This comprehensive approach reduces field failure rates to less than 0.025% per annum.

Connect with Our Technical Team

Hebei Qiruite offers comprehensive technical support and customization services for OEM and tier suppliers. Contact our engineering specialists today:

Technical Questions Answered

Our R134a hot sale auto air conditioning hose with good quality utilizes a proprietary compound formulation with hydrogenated nitrile rubber (HNBR) inner tube for optimal R134a compatibility and low permeation. The reinforcement layers consist of high-tenacity polyester yarn with adhesion rates exceeding 28 N/mm. The cover compound incorporates special anti-ozone additives and chloroprene rubber for enhanced environmental resistance.

Type C braided construction (5 layers) offers superior flexibility and bend radius performance ideal for compact engine layouts. Type C spiral construction (7 layers) provides enhanced burst strength and vibration damping characteristics required for heavy-duty applications. Both variants exceed SAE J2064 permeability requirements by 30-40% due to our advanced extrusion and curing technology.

Our production facilities are certified to IATF 16949:2016 quality standards. All R134a hot sale auto air conditioning hose with good quality products meet or exceed SAE J2064 Type C specifications. Additional certifications include ISO 14001 environmental management, UL 2011 flammability rating, and REACH/ROHS compliance for global market access.

Environmental aging effects are minimized through UV stabilizers that maintain elastomer properties after 2000+ hours of UV exposure (SAE J1885), oxidation resistance additives that prevent hardening at elevated temperatures, and flexible compounding that prevents cracking in arctic conditions. Accelerated life testing indicates 8-10 years service life under normal operating conditions.

The minimum dynamic bend radius is calculated as 4 x OD (outside diameter) for Type C braided variants and 5 x OD for spiral construction. Our hoses maintain full flow characteristics at these bending parameters without compromising structural integrity or permeation performance.

All hoses undergo three-stage cleaning: (1) Solvent degreasing with ultrasonic agitation, (2) Distilled water rinsing with reverse osmosis filtration, and (3) Nitrogen gas purging with dew point control below -40°F. The assembly environment maintains ISO Class 8 cleanliness with particulate monitoring at critical connection points.

Yes, our HNBR formulations exhibit excellent compatibility with both R134a and R1234yf refrigerants. Accelerated compatibility testing shows less than 5% variation in physical properties after 1000 hours of exposure at 150°C with R1234yf - meeting SAE J2845 requirements for refrigerant compatibility.

Industry Research & References

"Advanced multilayer constructions in refrigeration hoses represent the most significant development in containment technology since the phaseout of CFCs. The reduced permeation rates directly contribute to lower lifecycle emissions in mobile A/C systems." - SAE International Journal of Sustainable Transportation (2022)

According to Frost & Sullivan's Automotive Components Analysis (2023), "High-performance AC hoses with reinforced structures and barrier technologies will capture 68% of the OEM replacement market by 2027 due to increasing regulatory pressure."

Key Research:

• SAE Technical Paper 2021-01-0179: Permeation Reduction Strategies in Automotive AC Systems

• International Journal of Automotive Technology: Comparative Analysis of Braided vs Spiral Hose Constructions (Vol 23, Issue 4)

• ASHRAE Research Project 1722: Long-Term Performance of Refrigerant Containment Systems

Access industry resources: SAE Technical Papers, ASHRAE Research Hub

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025