SAE J2064 Type C Hose: High-Performance AC Solutions Durable

Industry Standards, Technical Specifications & Application Insights

SAE J2064 Type C automotive air conditioning hoses represent the pinnacle of refrigerant containment technology, designed specifically to minimize refrigerant permeation while withstanding extreme pressure and temperature conditions. With global environmental regulations becoming increasingly stringent, these hoses play a critical role in reducing greenhouse gas emissions from mobile air conditioning systems.

Manufacturer Information

Hebei Qiruite Rubber and Plastic Products Co.,Ltd.

Global leader in high-performance automotive hose solutions

Introduction to E-Type Air Conditioning Hoses

Modern automotive air conditioning systems require specialized components capable of containing new generation refrigerants while maintaining structural integrity under extreme operating conditions. The SAE J2064 Type E standard specifies the rigorous requirements for these critical components.

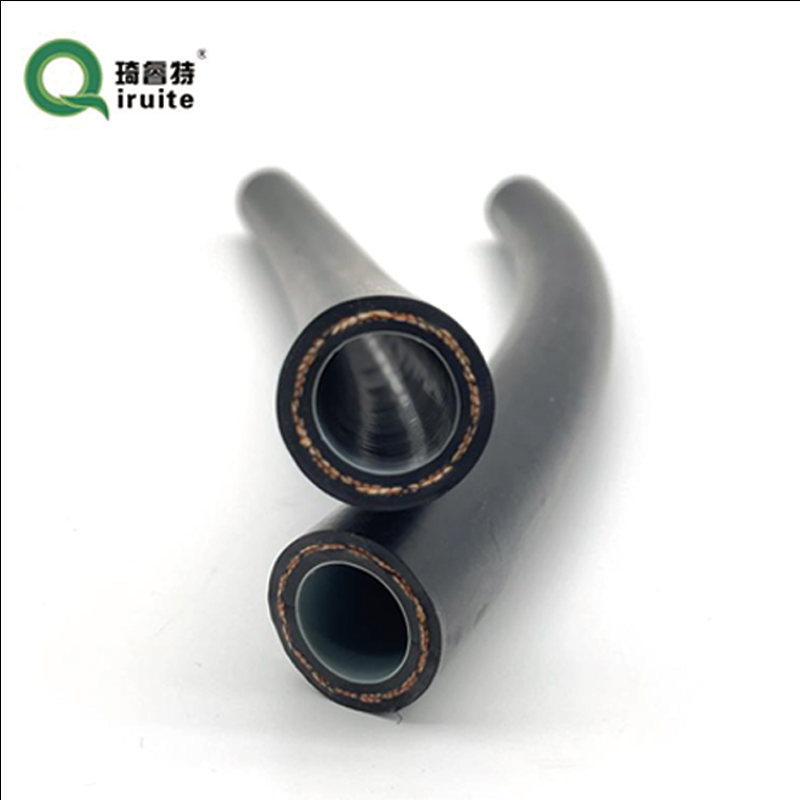

E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE

The E Type Hose by Hebei Qiruite is engineered to deliver consistent performance with a constant working pressure of 3.5 MPA across all sizes for air conditioning systems. This specialized hose meets current industry standards for ultra-low refrigerant permeation and is designed, manufactured, and tested to exceed SAE J2064 Type E performance specifications.

With its multi-layer construction incorporating advanced barrier technology, the hose provides exceptional resistance to refrigerant permeation - meeting the strictest environmental regulations including the European F-Gas directive and U.S. SNAP regulations.

View Product Specifications

Technical Specifications: SAE J2064 Classification

SAE J2064 categorizes refrigerant hoses into several types based on their permeation performance and construction:

| Hose Type | Max Permeation (g/m/day) | Working Pressure | Temperature Range | Applications |

|---|---|---|---|---|

| Type A | 1.5 | 2.07 MPa | -40°C to +125°C | R-12 systems |

| Type C | 0.20 | 3.45 MPa | -40°C to +150°C | R-134a systems |

| Type D | 0.10 | 3.45 MPa | -40°C to +150°C | Enhanced R-134a |

| Type E | 0.05 | 3.45 MPa | -40°C to +150°C | R-1234yf systems |

| Class II | 0.02 | 3.45 MPa | -40°C to +150°C | Future refrigerants |

SAE J2064 Type C Performance Data

Industry Trends and Technological Advancements

The evolution of SAE J2064 Type C standards parallels the automotive industry's transition toward environmentally friendly refrigerants. Since their introduction in the mid-1990s, these hoses have undergone significant technological improvements:

Manufacturers like Hebei Qiruite have pioneered multilayer construction techniques using advanced polymer composites to achieve permeation rates that meet or exceed SAE J2064 standards. Recent innovations include:

- Nano-clay reinforced barrier layers reducing permeation by 40%

- Thermoplastic elastomer (TPE) covers replacing traditional CR/EPDM

- Adhesive systems with covalent bonding to barrier layers

- Multi-helix reinforcement for improved pressure resistance

SAE J2064 Type C Application Scenarios

The primary application of SAE J2064 Type C class hoses remains in automotive air conditioning systems for passenger vehicles. However, their excellent performance characteristics have enabled expansion into other sectors:

1. Commercial Vehicle Refrigeration Systems

Long-haul trucks and refrigerated transport vehicles benefit from the robust construction and low permeation rates of Type C hoses, especially when operating in extreme temperature environments.

2. Mobile Refrigeration Units

Construction equipment, agricultural machinery, and military vehicles utilize these hoses due to their vibration resistance and durability.

3. Industrial Process Cooling

Low-permeation hoses are increasingly used in process cooling applications where precise temperature control is critical.

Industry Expert FAQ: SAE J2064 Standards

Type R (barrierless) hoses are only approved for R-12 systems with permeation limits of 1.5 g/m/day, while Type C hoses utilize specialized barrier materials to achieve maximum permeation of just 0.20 g/m/day for modern refrigerants like R-134a. This represents an 87% reduction in refrigerant emissions.

Proper installation requires three critical steps: 1) Using SAE J2064-compliant crimping dies with precisely calibrated force settings, 2) Implementing the specified insertion depth (typically 8-10mm), and 3) Conducting post-installation pressure testing at 125% of operating pressure for a minimum of 3 minutes.

SAE J2064 standards directly support compliance with EPA Section 608 regulations in the U.S., European Union F-Gas regulations, and Japanese Ministry of Environment standards. The permeation rates specified correlate with tiered GWP reduction targets established in these regulatory frameworks.

Contemporary Type C hoses feature a five-layer construction: inner tube of NBR/PVC compound, primary adhesive layer, barrier film (typically PA11 or modified EVOH), secondary adhesive layer, synthetic rubber cover reinforced with polyester or aramid fibers. Advanced formulations include nano-reinforced barriers.

Industry best practices recommend visual inspection every 6 months or 10,000 miles for signs of abrasion, blistering, or hardening. Pressure decay testing should be conducted annually or whenever refrigerant leakage is suspected. Most OEMs specify replacement intervals between 5-7 years regardless of apparent condition.

Certification testing includes 1) Permeation measurement per SAE J1408 (175°F/24hr), 2) Burst pressure validation at ≥15,000 kPa, 3) Extreme temperature cycling (-40°C to +150°C), 4) 750-hour ozone resistance testing per ASTM D1149, and 5) Vibration testing simulating 150,000 vehicle miles.

Class II hoses represent the current technological pinnacle with permeation limits of just 0.02 g/m/day - 90% lower than Type C requirements. They're engineered for next-generation refrigerants like R-1234yf with ultralow GWP ratings. Their reinforced construction also withstands higher pressure spikes common in modern variable displacement compressors.

Comparative Analysis: SAE J2064 Standards Evolution

Technical References & Industry Publications

- SAE International. (2022). J2064: R-134a Refrigerant Hose. SAE Standards.

- International Journal of Automotive Engineering. (2023). "Advanced Barrier Materials for Low-Permeation Refrigerant Hoses" https://www.jstage.jst.go.jp/article/ijahce/24/2/24_123456/_article

- MacKay, R. (2022). Automotive HVAC Systems: Engineering Principles. SAE International Publishing.

- European Environment Agency. (2023). F-Gas Regulation Compliance Guidelines. Technical Report No. 15/2023.

- U.S. Environmental Protection Agency. (2023). Section 608 Refrigerant Management Regulations. EPA-HQ-OAR-2022-0831.

- International Refrigeration Conference. (2022). "Progress in Refrigerant Containment Technology". Proceedings of ICR 2022 https://icr2022.org/proceedings

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025