SAE J1401 Brake Hose Specifications: DOT-Approved, OEM-Grade

What to Know About Sae J1401 Brake Hose Specifications in 2025

If you’re sourcing brake lines today, you’ll see a quiet but real shift: OEMs and serious aftermarket brands are tightening to SAE J1401 and FMVSS 106, while fleets are asking for traceability and longer salt-spray performance. The SAE J1401 Brake Hose—sometimes nicknamed “oil brake hose” in the trade—has become the baseline for hydraulic brake systems on cars, light trucks, and trailers. Origin-wise, this line from Ningjin County, Hebei Province keeps popping up in quotes because it balances cost with compliance. And to be honest, that’s what most buyers want.

Industry snapshot

-

- Increasing use of braided polyester/nylon reinforcements for weight savings and consistent expansion.

- More labs testing to FMVSS 106 whip resistance and ozone aging, not just burst pressure—smart move.

- Buyers requesting IATF 16949/ISO 9001 certificates plus PPAP for OEM projects.

- Custom assemblies (banjo, crimp sleeves, protective sleeves) are now routine, even for midsize distributors.

Technical overview

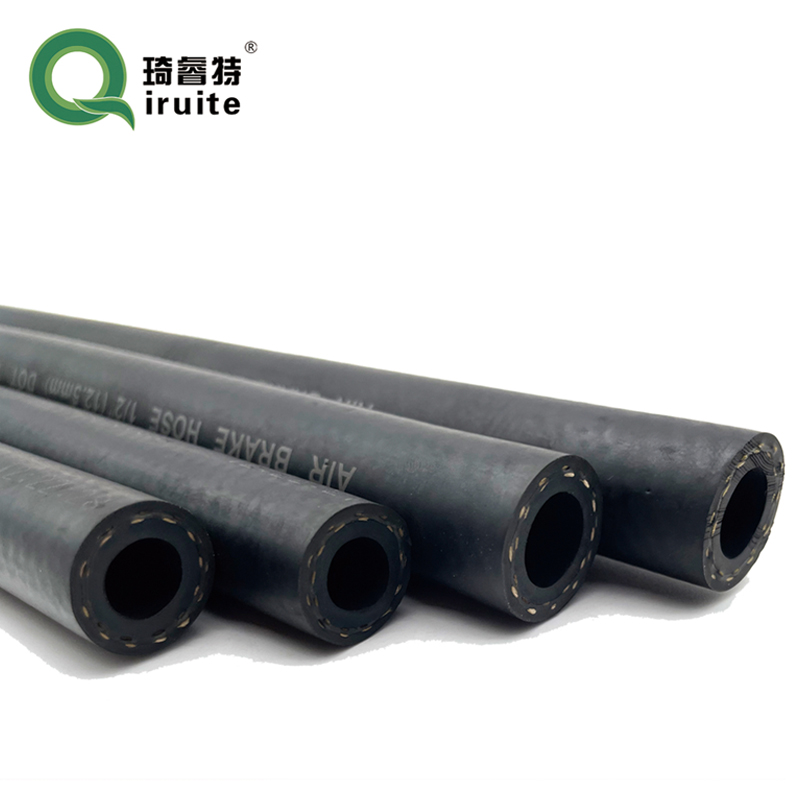

Construction: EPDM inner tube (compatible with DOT 3/4/5.1), braided polyester or nylon reinforcement, EPDM/CR outer cover with ozone and abrasion resistance. Manufactured by extrusion → braiding → vulcanization → cutting → crimping/assembly → proof testing. Many customers say the expansion stability under high heat is the “make-or-break” attribute on long descents.

| Parameter | Typical Value (≈) | Notes (real-world use may vary) |

|---|---|---|

| Inner diameter | 3.2–3.5 mm (1/8") | Other sizes on request |

| Working pressure | 1,000–1,500 psi | System-dependent |

| Burst pressure | ≥ 8,000–10,000 psi | Meets SAE J1401/FMVSS 106 |

| Temperature range | -40°C to +120°C (spikes to +150°C) | Short-term peaks only |

| Volumetric expansion | Low, J1401-compliant | Keeps pedal feel firm |

| Ozone/salt resistance | Passes ozone; 96–240 h NSS | ISO 9227 guidance |

Applications and advantages

-

- Passenger cars, pickups, vans, trailers (hydraulic).

- Stable pedal feel thanks to low expansion braids; surprisingly noticeable on heavier SUVs.

- Custom lengths, fittings (banjo, male/female, quick-connect), color sleeves, laser marks for traceability.

Process & testing flow

Materials selection → extrusion (EPDM) → braiding (polyester/nylon) → vulcanization → fitting crimping → 100% proof test (often 3,000 psi) → whip test (per FMVSS 106) → ozone aging → salt spray → cleanliness check (per ISO guidelines). Typical service life: 5–8 years in mixed climates; heavy road salt may shorten that—I’ve seen fleets swap at 4–5 years proactively.

Vendor landscape (quick comparison)

| Vendor | Certifications | MOQ | Lead Time | Customization | Price |

|---|---|---|---|---|---|

| QRT (Ningjin, Hebei) | ISO 9001; IATF 16949 (on request) | ≈ 500–1,000 pcs | 3–5 weeks | High (fittings, sleeves, print) | $$ (value) |

| Importer A | ISO 9001 | ≈ 2,000 pcs | 6–8 weeks | Medium | $ |

| Boutique Racing | IATF 16949; ISO 17025 lab | ≈ 100 pcs | 2–3 weeks | Very high | $$$ |

Case notes and feedback

- Regional delivery fleet: switched to Sae J1401 Brake Hose Specifications-compliant assemblies with anti-abrasion sleeves; reported fewer pedal-sponginess complaints after 12 months.

- Trailer OEM: customized lengths and banjo angles reduced assembly time by ~11%—small but real.

- Enthusiast shop: noticed better modulation on heavy-braking tracks; they still inspect every event (as they should).

Buying checklist

-

- Confirm FMVSS 106 and Sae J1401 Brake Hose Specifications test reports (burst, whip, expansion, ozone).

- Ask for material declarations (EPDM compatibility with DOT 3/4/5.1).

- Specify fittings, torque, crimp OD, and cleanliness targets; request PPAP for OEM.

- For snow-belt markets, request extended salt-spray validations (≥ 240 h if possible).

Bottom line: a solid J1401 hose isn’t glamorous, but it’s the backbone of consistent braking. Get the data, lock the specs, and you’ll sleep better—all while keeping costs sane.

Authoritative citations

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025