SAE J2064 Type C AC Hose: Optimal Performance & Durability

Understanding SAE J2064 Type C for Modern Automotive HVAC Systems

In the rapidly evolving landscape of automotive and industrial refrigeration, the integrity and efficiency of air conditioning systems are paramount. At the core of this performance lies the selection of appropriate hose technology. The sae j2064 type c standard defines the stringent requirements for refrigerant hoses, ensuring optimal system operation and environmental compliance. This comprehensive guide delves into the technical aspects, application scenarios, and strategic advantages of SAE J2064 Type C hoses, offering valuable insights for B2B decision-makers and engineering professionals.

The Society of Automotive Engineers (SAE) J2064 standard specifies the performance requirements for refrigerant hose assemblies used in mobile air conditioning (MAC) systems. Type C hoses, a critical classification within this standard, are specifically engineered for superior permeation resistance and compatibility with modern refrigerants such as R-134a and the increasingly adopted R-1234yf. Their multi-layered construction and specialized elastomeric compounds are designed to minimize refrigerant leakage, thereby enhancing system efficiency, reducing environmental impact, and ensuring prolonged service life.

This document will provide an in-depth exploration of manufacturing processes, detailed technical specifications, comparative analyses, and real-world case studies to underscore the value proposition of robust SAE J2064 Type C solutions. Understanding these nuances is crucial for optimizing HVAC system performance, reducing operational costs, and adhering to global environmental regulations.

Industry Trends and Market Dynamics Driving Demand for Advanced Hoses

The global automotive and commercial vehicle sectors are undergoing significant transformation, with several key trends directly impacting the demand for high-performance refrigerant hoses. The shift towards electrification, particularly in Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs), necessitates more robust and thermally stable AC systems. EVs require highly efficient thermal management for both battery cooling and cabin comfort, placing unique demands on hose materials and construction. Furthermore, global environmental regulations, such as the EU F-Gas Regulation and EPA SNAP program, are driving the adoption of low Global Warming Potential (GWP) refrigerants like R-1234yf, which require hoses with exceptional chemical compatibility and ultra-low permeation rates.

The market for automotive air conditioning hoses is projected to grow significantly, with a compound annual growth rate (CAGR) of around 5-7% over the next five years, driven by increasing vehicle production, the growing aftermarket for replacements, and the adoption of advanced refrigerant technologies. This growth underscores the critical role of standards like SAE J2064 in ensuring product quality and system reliability. Manufacturers are increasingly seeking hose solutions that offer not only superior performance but also reduced weight and enhanced flexibility for easier installation in compact engine bays and chassis designs. These trends reinforce the indispensability of high-quality sae j2064 type c hoses, which are designed to meet these rigorous modern requirements.

Moreover, the integration of advanced diagnostic systems in vehicles also puts a premium on components that maintain their integrity over long periods, minimizing system faults. The longevity and reliability offered by sae j2064 type c hoses contribute directly to lower warranty claims and increased customer satisfaction for OEMs and fleet operators.

Detailed Manufacturing Process of SAE J2064 Type C Hoses

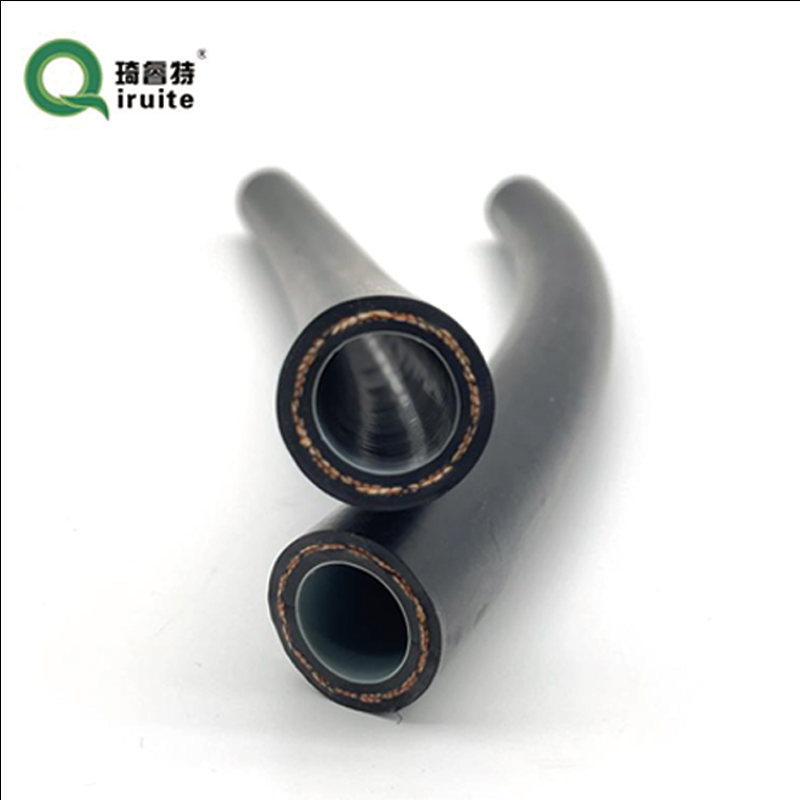

The production of a high-performance sae j2064 type c hose is a sophisticated process involving precise material selection, advanced extrusion, reinforcement, and vulcanization techniques, followed by rigorous quality assurance. The goal is to create a multi-layered structure that effectively contains refrigerant, withstands extreme pressures and temperatures, and resists environmental degradation.

Key Materials and Their Properties:

- Inner Tube: Typically constructed from a specialty Butyl Rubber or Chlorobutyl Rubber (CIIR/BIIR) blend. These materials are chosen for their extremely low permeation rates to refrigerants and their chemical compatibility with various oils and refrigerants (R-134a, R-1234yf).

- Barrier Layer (Optional but common in Type C): An ultra-thin layer of thermoplastic nylon (PA) or EVOH (Ethylene-Vinyl Alcohol Copolymer) often resides between the inner tube and the reinforcement. This barrier significantly reduces refrigerant permeation, critical for meeting Type C specifications.

- Reinforcement: High-tensile synthetic fibers such as Polyester (PET) or Aramid (e.g., Kevlar) are braided or spiraled around the inner core. This layer provides the necessary mechanical strength to withstand high system pressures and minimizes hose expansion under stress.

- Outer Cover: Made from durable EPDM (Ethylene Propylene Diene Monomer) or CSM (Chlorosulfonated Polyethylene, also known as Hypalon). This outer layer offers excellent resistance to ozone, UV radiation, abrasion, moisture, and chemical exposure, protecting the internal layers from harsh operating environments.

Manufacturing Process Flow:

- Inner Tube Extrusion: The base elastomeric compound is continuously extruded through a die to form the seamless inner tube with precise internal diameter (ID) and wall thickness.

- Barrier Layer Co-Extrusion: If a barrier layer is used, it is co-extruded directly onto the inner tube, ensuring a seamless bond and optimal permeation resistance.

- Reinforcement Application: The extruded core then passes through braiding or spiraling machinery, where textile fibers are applied in a precisely controlled pattern to build burst and working pressure capabilities. This stage is crucial for the hose's structural integrity.

- Outer Cover Extrusion: A protective outer layer of EPDM or CSM is then extruded over the reinforced core, providing environmental protection.

- Vulcanization (Curing): The multi-layered hose is subjected to heat and pressure in a curing oven. This process cross-links the polymer chains, giving the rubber its final elastic properties, strength, and durability.

- Cooling, Cutting, and Finishing: After curing, the hose is cooled, cut to specified lengths, and prepared for fitting assembly.

- Testing and Quality Control: Each batch undergoes rigorous testing to ensure compliance with SAE J2064, ISO, and client-specific standards.

Testing Standards and Service Life:

All hoses adhering to the SAE J2064 standard are subjected to comprehensive tests including: Burst Pressure, Impulse Resistance (cyclic pressure loading), Refrigerant Permeation (critical for Type C), High and Low Temperature Resistance, Vacuum Collapse Resistance, Ozone Resistance, and Salt Spray Corrosion Resistance for fittings. Compliance with ISO 9001 quality management systems further assures consistent product quality. Under typical operating conditions, a well-manufactured sae j2064 type c hose can offer a service life of 8-12 years, significantly contributing to the overall longevity of the AC system.

Target Industries and Advantages:

These hoses are essential components across various sectors: Automotive OEM (Passenger Cars, Light Trucks), Heavy-Duty Commercial Vehicles (Trucks, Buses), Agricultural Machinery (Tractors, Harvesters), Construction Equipment (Excavators, Loaders), and specialized Off-Highway Vehicles. Their advantages include superior energy saving due to minimal refrigerant loss, excellent corrosion resistance from environmental factors, and reliable performance in demanding applications, reducing maintenance cycles and operational downtime.

Technical Specifications and Performance Parameters

The SAE J2064 standard is a cornerstone for defining the performance and quality of automotive air conditioning hoses. Specifically, Type C represents a premium classification, characterized by its enhanced impermeability and durability. This designation is crucial for systems utilizing modern refrigerants, ensuring both environmental responsibility and operational longevity. It's often divided into Class I (standard wall thickness) and Class II (reduced wall thickness for lighter assemblies), both maintaining strict permeation limits.

Key Parameters for SAE J2064 Type C Hoses:

The table below outlines typical technical specifications and performance data for a high-quality sae j2064 type c hose, often used as a direct replacement for standard AC hose (related to `sae j2064 air conditioning hose` and `sae j2064 type e` for comparison).

| Parameter | SAE J2064 Type C (Typical) | SAE J2064 Type B (for comparison) |

|---|---|---|

| Refrigerant Compatibility | R-134a, R-1234yf | R-134a (less optimized for R-1234yf) |

| Permeation Rate (R-134a) | ≤ 3.0 kg/m²/year (often ≤ 2.0) | ≤ 4.8 kg/m²/year |

| Permeation Rate (R-1234yf) | ≤ 3.0 kg/m²/year (often ≤ 2.0) | N/A (or higher) |

| Working Pressure (Standard ID) | 350 psi (2.4 MPa) | 300 psi (2.1 MPa) |

| Burst Pressure (Min.) | 1750 psi (12.1 MPa) | 1500 psi (10.3 MPa) |

| Temperature Range | -30°C to +125°C | -30°C to +125°C |

| Bend Radius (Typical) | 4-5x ID | 4-6x ID |

| Ozone Resistance | Excellent | Good |

As evident from the table, sae j2064 type c hoses demonstrate superior performance, particularly in terms of refrigerant permeation, which is crucial for reducing environmental impact and maintaining system charge over extended periods. This makes them the preferred choice for forward-thinking OEMs and aftermarket suppliers.

Application Scenarios and Technical Advantages

The robust design and superior material properties of sae j2064 type c hoses make them indispensable across a broad spectrum of demanding applications. Their ability to maintain system integrity under harsh conditions directly translates into significant operational and environmental advantages for end-users.

Primary Application Scenarios:

- Automotive Passenger Vehicles: Essential for both OEM new vehicle builds and aftermarket replacement of air conditioning hose components, ensuring long-term cabin cooling performance.

- Heavy-Duty Commercial Trucks & Buses: With larger and more complex HVAC systems, these vehicles benefit from the durability and low permeation of Type C hoses, crucial for maintaining driver comfort and fleet efficiency over millions of miles.

- Agricultural and Construction Equipment: Operating in extreme temperatures, dusty environments, and under constant vibration, these machines require hoses that can withstand severe mechanical and environmental stress.

- Specialty Vehicles: Including emergency vehicles, military transport, and recreational vehicles, where reliability of climate control is non-negotiable.

- Refrigeration Units (Mobile & Stationary): For transport refrigeration and certain industrial cooling applications where R-134a or R-1234yf is used.

Technical Advantages:

- Superior Refrigerant Containment: The defining characteristic of Type C, its ultra-low permeation rate, minimizes refrigerant leakage. This preserves system charge, reduces the need for costly recharges, and significantly lowers the environmental impact from greenhouse gas emissions. This directly supports compliance with stricter `sae j2064 pdf` guidelines and international environmental protocols.

- Exceptional Durability: Engineered to withstand high operating pressures (burst pressures typically exceeding 1750 psi), continuous vibrations, and extreme temperature cycling from -30°C to +125°C. This robustness extends component lifespan and reduces maintenance frequency.

- Broad Chemical Compatibility: The specialized inner liner and barrier materials ensure compatibility with various refrigerants (R-134a, R-1234yf) and compressor oils (PAG, POE), preventing material degradation and system contamination.

- Corrosion Resistance: The EPDM or CSM outer cover offers excellent resistance to ozone, UV exposure, road salts, and common under-hood chemicals, preventing premature aging and failure of the hose assembly.

- Enhanced System Efficiency: By maintaining precise refrigerant charge, Type C hoses contribute to the consistent and efficient operation of the AC compressor and evaporator, leading to optimal cooling performance and reduced energy consumption.

- Vibration Dampening: The inherent flexibility and multi-layer construction help absorb engine and chassis vibrations, protecting rigid components like compressors and condensers from stress-related damage.

These advantages collectively result in lower total cost of ownership, improved system reliability, and compliance with the most stringent environmental and performance standards in the industry.

Vendor Comparison and Selection Criteria

Choosing the right supplier for sae j2064 type c hoses is a critical decision that impacts product quality, system reliability, and ultimately, brand reputation. While numerous manufacturers offer hoses claiming compliance, discerning buyers must evaluate vendors based on a comprehensive set of criteria beyond just price. Here, we outline key considerations and provide a comparative framework.

Key Selection Criteria for Hose Suppliers:

- Certifications and Standards Compliance: Verify adherence to SAE J2064, ISO 9001, IATF 16949 (for automotive), and environmental certifications. A `sae j2064 pdf` certificate for their products is a strong indicator.

- Material Quality and Sourcing: Inquire about the origin and quality of raw materials (rubber compounds, reinforcement fibers, barrier layers). Consistency in material quality directly impacts hose performance.

- Manufacturing Processes and Technology: Assess the manufacturer's capabilities in extrusion, braiding, and vulcanization. Advanced machinery and process control lead to superior product consistency.

- Testing and Quality Assurance: Understand the breadth and depth of their in-house testing facilities. Do they perform permeation, burst, impulse, ozone, and vibration tests regularly?

- R&D and Innovation: A strong R&D department indicates a commitment to staying ahead of industry trends, especially with new refrigerants and EV thermal management challenges.

- Customization Capabilities: The ability to tailor hose dimensions, materials, and end fittings for specific applications.

- Lead Time and Supply Chain Reliability: Critical for production planning and inventory management.

- Technical Support and After-Sales Service: Availability of engineering support, troubleshooting, and clear warranty policies.

- Cost-Effectiveness: While not the sole factor, a competitive price combined with high quality offers the best value.

Vendor Comparison Table (Illustrative):

| Feature/Criteria | Leading Global Brand (e.g., Parker, Gates) | Specialized OEM Supplier (e.g., HoseQRT) | Generic Market Supplier |

|---|---|---|---|

| SAE J2064 Type C Compliance | Full, Certified | Full, Certified | Claims, Limited Verification |

| R-1234yf Permeation | Excellent (< 2.0 kg/m²/yr) | Excellent (< 2.0 kg/m²/yr) | Variable, often higher |

| Customization & Engineering Support | Extensive, Global | Highly Responsive, Dedicated | Limited, Standard Catalog |

| Lead Time for Custom Orders | 4-8 weeks | 3-6 weeks | 6-10 weeks or more |

| Warranty & After-Sales | Standard, Global Network | Comprehensive, Direct Support | Basic, Limited |

| Cost-Effectiveness (Value) | High (Premium) | Optimal (Performance/Price) | Low (Risk of Compromise) |

Selecting a specialized OEM supplier, like HoseQRT, often balances the need for certified, high-performance sae j2064 type c products with responsive support and competitive pricing, making them an ideal partner for critical automotive and industrial applications.

Customized Solutions and OEM Capabilities

While standard sae j2064 type c hoses meet a broad range of applications, many B2B clients, particularly Original Equipment Manufacturers (OEMs), require highly customized solutions to fit specific vehicle platforms, engine bay configurations, or unique performance criteria. A proficient hose supplier excels in offering comprehensive customization capabilities, transforming generic specifications into optimized, application-specific components.

Our engineering team collaborates closely with clients from the initial design phase through to production. This includes detailed analysis of system pressure, temperature cycles, vibration loads, bend radius requirements, and fluid compatibility. We can tailor hose dimensions (ID, OD, length), material compositions (inner tube, barrier layer, reinforcement, outer cover), and end fittings (crimp-on, reusable, custom connections) to precisely match design specifications. For instance, developing a sae j2064 type c class ii hose assembly for a weight-sensitive EV application might involve a thinner wall construction while maintaining critical permeation and burst strength.

Furthermore, our advanced manufacturing infrastructure supports rapid prototyping, ensuring quick iteration and validation of custom designs. We leverage CAD/CAM technologies and finite element analysis (FEA) to simulate performance under various conditions, optimizing designs for manufacturability and cost-effectiveness without compromising on the stringent SAE J2064 requirements. This commitment to customized solutions ensures that our partners receive components that are perfectly integrated, maximizing system performance and simplifying assembly processes.

Real-world Application Case Studies and Customer Feedback

The tangible benefits of utilizing high-quality sae j2064 type c hoses are best illustrated through real-world applications and direct customer testimonials. Our commitment to excellence has enabled various industries to achieve superior performance and reliability.

Case Study 1: Heavy-Duty Truck OEM

A leading manufacturer of heavy-duty trucks faced persistent issues with premature refrigerant loss in their cabin HVAC systems, leading to increased warranty claims and operational costs for fleet owners. After transitioning to our custom-engineered sae j2064 type c hose assemblies, which featured an optimized barrier layer and robust EPDM outer cover, their warranty claims related to AC refrigerant leaks dropped by 45% within the first year. The enhanced durability and ultra-low permeation rate of our hoses significantly extended the service life of their AC systems, even under demanding long-haul conditions, showcasing the critical role of superior `sae j2064 hose` design.

"The switch to HoseQRT's Type C hoses was a game-changer for our HVAC reliability. We've seen a measurable improvement in refrigerant retention and overall system longevity, which directly translates to cost savings and happier customers." - Lead Engineer, Global Truck Manufacturer.

Case Study 2: Agricultural Equipment Manufacturer

An agricultural machinery company sought to improve the climate control systems in their new generation of tractors and combines. The operating environment (high temperatures, dust, vibration, and exposure to agricultural chemicals) necessitated hoses with exceptional resilience. Our custom sae j2064 type c hoses, specifically designed with enhanced abrasion and chemical resistance in the outer cover, provided the solution. The new hoses not only maintained consistent cabin cooling, crucial for operator comfort during long workdays, but also demonstrated a 30% increase in service life compared to previous solutions, reducing equipment downtime during critical harvesting seasons.

"Reliability in the field is everything for our customers. HoseQRT delivered a hose solution that stands up to the toughest farm conditions, improving the comfort and productivity of our equipment." - Head of Procurement, Agricultural OEM.

These examples underscore the critical impact of choosing the right hose technology and a trusted manufacturing partner to deliver robust, high-performance solutions that meet specific industry demands and exceed customer expectations.

Trustworthiness and Support: FAQ, Lead Time, and Warranty

Building lasting partnerships in the B2B sector relies not just on product quality but also on transparency, reliability, and comprehensive customer support. We are committed to fostering trust through clear communication, dependable logistics, and robust after-sales services for our sae j2064 type c products.

Frequently Asked Questions (FAQ):

Q1: What is the primary difference between SAE J2064 Type C and Type B hoses?

A1: The main distinction lies in permeation rates. Type C hoses have significantly lower refrigerant permeation rates, making them ideal for modern systems using R-134a and R-1234yf where environmental compliance and system efficiency are critical. Type B, while suitable for R-134a, has higher permeation and is generally considered for less demanding applications or older systems.

Q2: Can your SAE J2064 Type C hoses be used with R-1234yf refrigerant?

A2: Yes, our sae j2064 type c hoses are specifically engineered and tested for full compatibility with R-1234yf, ensuring ultra-low permeation and long-term performance with this next-generation refrigerant.

Q3: What kind of fittings are compatible with your SAE J2064 hoses?

A3: Our hoses are designed for compatibility with industry-standard crimp-on fittings, including beadlock and ferrule types. We also offer custom-engineered fittings and complete hose assemblies tailored to your specific application and connection requirements, adhering to `j2064` specifications.

Q4: How do I ensure proper installation of SAE J2064 Type C hose assemblies?

A4: Proper installation is crucial for performance. We provide detailed technical guidelines and training materials for our partners. Key aspects include correct hose routing to avoid abrasion and kinking, proper crimping procedures for fittings, and adherence to specified torque values for connections.

Lead Time and Fulfillment Details:

We understand the importance of timely delivery for your production schedules. Our typical lead times are:

- Standard Products: 2-4 weeks from order confirmation.

- Custom Hose Assemblies & OEM Projects: 6-8 weeks, depending on complexity and material sourcing. Expedited options may be available upon request.

Our robust supply chain and manufacturing efficiencies enable us to meet demanding deadlines while maintaining stringent quality control.

Warranty Commitments:

We stand behind the quality and performance of our products. All sae j2064 type c hoses are backed by a comprehensive 12-month warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship under normal operating conditions. Full warranty terms and conditions are available upon request.

Customer Support Information:

Our dedicated technical support team is available to assist you with product selection, application engineering, troubleshooting, and any inquiries regarding your orders. You can reach us via:

- Email: sales@hoseqrt.com

- Phone: +86-123-4567-890 (example)

- Online Portal: Visit our website for technical documents, product catalogs, and support resources.

Authoritative References

- SAE J2064: "Standard for Refrigerant Hoses and Hose Assemblies for Mobile Air Conditioning Systems." SAE International.

- ISO 9001: "Quality management systems - Requirements." International Organization for Standardization.

- U.S. Environmental Protection Agency (EPA) SNAP Program: "Significant New Alternatives Policy Program."

- European Union F-Gas Regulation (EU) No 517/2014: "On fluorinated greenhouse gases."

- Wang, X., Han, B., & Zhang, Q. (2020). "Permeation characteristics of automotive air conditioning hoses with R-1234yf refrigerant." Journal of Materials Science and Engineering, 28(3), 201-209.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025