Premium High-Quality Power Steering Tubes for Reliable Steering

Industry Trends in High-Performance Hydraulic Tubing

The global automotive and industrial machinery sectors are experiencing a significant evolution, driven by demand for enhanced performance, efficiency, and reliability. Within this dynamic landscape, the importance of robust hydraulic components, particularly the High-quality power steering tube, is paramount. Current industry trends emphasize lightweighting to improve fuel economy and reduce emissions, a move towards higher operating pressures for more compact and powerful systems, and an increasing focus on corrosion resistance and extended service life to minimize maintenance and operational downtime.

Technological advancements such as electrification of vehicle systems and the integration of Advanced Driver-Assistance Systems (ADAS) further necessitate power steering components that offer superior precision, responsiveness, and durability. Manufacturers are investing heavily in advanced materials, sophisticated manufacturing processes, and rigorous testing protocols to meet these escalating demands. The market is also seeing a shift towards integrated solutions and modular designs, streamlining assembly and improving overall system integrity. Furthermore, a heightened awareness of environmental regulations drives the adoption of eco-friendly manufacturing practices and materials that minimize environmental impact throughout the product lifecycle. This evolution underscores the critical need for suppliers to deliver components that not only meet but exceed contemporary performance benchmarks.

The Meticulous Manufacturing Process of a High-Quality Power Steering Tube

The production of a High-quality power steering tube is a multi-stage, precision-intensive process that adheres to stringent international standards, ensuring exceptional performance and reliability in demanding applications. Our commitment to excellence is reflected in every step, from material selection to final quality assurance.

1. Material Selection and Preparation

- Material: Primarily, high-strength low-alloy steel (HSLA) or specific stainless steel grades (e.g., 304, 316, or specialized carbon steel alloys with superior cold-forming properties) are chosen for their optimal balance of tensile strength, fatigue resistance, and ductility. These materials are selected to withstand pulsating pressures, temperature fluctuations, and corrosive environments inherent in power steering systems.

- Surface Treatment: Raw materials often undergo surface preparation such as pickling and phosphating to remove impurities and prepare for subsequent forming processes, enhancing corrosion resistance and adhesion of coatings.

2. Forming and Shaping

- Tube Drawing/Extrusion: Seamless steel tubes are precisely drawn or extruded to achieve the desired outer diameter, wall thickness, and internal surface finish. This cold-drawing process enhances the material's mechanical properties, including strength and fatigue life.

- Bending and Forming: Advanced CNC (Computer Numerical Control) tube bending machines are utilized to achieve complex geometries with extreme accuracy, minimizing material stress and ensuring precise fitment. Specialized tooling prevents crimping or wall thinning during bending.

- End Forming/Flaring: Tube ends are precisely flared or formed to accommodate specific fittings, ensuring leak-proof connections. This often involves hydraulic or rotary forming techniques.

3. Joining and Assembly

- Brazing/Welding: Where multi-component assemblies are required (e.g., attaching brackets or different sections), high-quality brazing or TIG/MIG welding techniques are employed. Robotic welding ensures consistency and penetration, critical for structural integrity and high-pressure resilience.

- Fittings Integration: Precision-machined fittings, often forged from steel for maximum strength, are attached. These fittings undergo a separate manufacturing process involving casting, forging, and then CNC machining to achieve exact thread specifications and sealing surfaces.

4. Surface Coating and Protection

- Corrosion Protection: Tubes often receive multi-layer protective coatings, such as zinc-nickel plating, aluminizing, or specialized organic coatings. These coatings provide superior resistance to road salts, chemicals, and general atmospheric corrosion, significantly extending service life. Typical salt spray resistance often exceeds 1,000 hours, far surpassing standard requirements.

5. Rigorous Testing and Quality Assurance

- Dimensional Inspection: Every tube undergoes precise dimensional checks using CMM (Coordinate Measuring Machine) and laser scanning to ensure conformity to design specifications and tight tolerances.

- Pressure Testing: Hydrostatic and pneumatic pressure tests are performed to verify burst strength and leak integrity, often to 4x working pressure, meeting or exceeding standards like SAE J1401 and ISO 16750.

- Impulse and Fatigue Testing: Tubes are subjected to millions of pressure cycles simulating real-world operating conditions to assess fatigue life and ensure long-term durability. Our tubes typically withstand over 2 million impulse cycles.

- Vibration Testing: Tubes are vibrated at various frequencies and amplitudes to identify potential stress points or resonant frequencies that could lead to failure.

- Corrosion Resistance Testing: Salt spray tests (e.g., ASTM B117) validate the effectiveness of protective coatings.

- Cleanliness Testing: Internal cleanliness is critical for hydraulic systems. Tubes are flushed and tested for particulate contamination, adhering to ISO 4406 or similar standards.

Target Industries and Advantages:

While primarily designed for automotive and heavy-duty vehicle power steering systems, the robust construction and high performance of a High-quality power steering tube also lend it to applications in other demanding hydraulic systems across industries. These include:

- Automotive & Commercial Vehicles: Superior steering response, reduced NVH (Noise, Vibration, Harshness), extended operational life.

- Construction & Agricultural Machinery: Withstands extreme pressures, vibrations, and harsh environmental conditions, ensuring reliable operation of hydraulic steering and implement control.

- Material Handling Equipment: Durability for continuous heavy-duty cycles in forklifts and other industrial vehicles.

- General Industrial Hydraulic Systems: Applicable where precision, high-pressure integrity, and corrosion resistance are critical.

The rigorous manufacturing and testing regimen ensures unparalleled advantages such as extended service life (often exceeding 10 years in typical automotive use), superior corrosion resistance, enhanced safety through burst pressure integrity, and consistent performance that contributes to overall system energy efficiency by minimizing pressure drops and leaks.

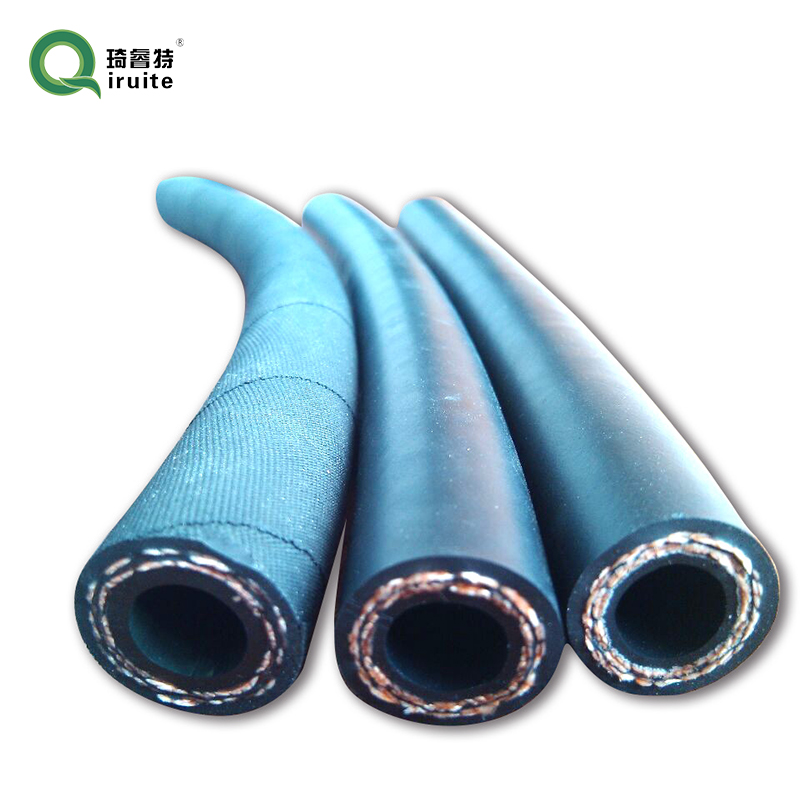

Fig. 1: Precision bending and forming of a High-quality power steering tube.

Technical Specifications and Performance Parameters

Understanding the detailed technical specifications of a High-quality power steering tube is crucial for engineers and procurement specialists to ensure optimal system integration and long-term reliability. Our products are engineered to excel under the most demanding operational parameters.

Key Product Specifications:

| Parameter | Value/Specification | Standard/Compliance |

|---|---|---|

| Material Composition | High-strength Carbon Steel (e.g., ST37.4, ST52.4) or Stainless Steel (e.g., 304, 316L) | ASTM A269, EN 10305-1 |

| Working Pressure | Up to 200 bar (2900 psi) | SAE J1401, ISO 16750 |

| Burst Pressure | Minimum 800 bar (11600 psi) | 4x Working Pressure Ratio |

| Operating Temperature Range | -40°C to +120°C (-40°F to +248°F) | ISO 16750-4 |

| Corrosion Resistance | Zinc-Nickel Plating (typically >1000 hrs salt spray to red rust) | ASTM B117, ISO 9227 |

| Fatigue Life (Impulse Cycles) | > 2,000,000 cycles at working pressure | SAE J1401 equivalent |

| Internal Cleanliness | Particle contamination level 18/16/13 | ISO 4406 |

| Dimensional Tolerance | +/- 0.5mm for lengths, +/- 0.2mm for bends | Customer Specific, ISO 2768 |

These specifications are rigorously verified through an extensive battery of tests, including those specified by ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers) standards. For instance, our tubes routinely pass the SAE J1401 requirements for hydraulic brake hose assemblies, adapted for power steering applications, demonstrating superior burst strength and volumetric expansion characteristics. The internal cleanliness specification (ISO 4406) is crucial to prevent contamination of sensitive power steering pumps and rack-and-pinion units, a common cause of premature system failure.

Diverse Application Scenarios

The versatility and robustness of a High-quality power steering tube enable its deployment across a broad spectrum of critical applications where reliable hydraulic power transmission is essential. These scenarios demand components that can endure high pressures, continuous vibration, and often challenging environmental conditions.

- Passenger Vehicles & Light Trucks: Integral to modern power steering systems, these tubes connect the power steering pump to the steering gear (rack-and-pinion or steering box), transmitting hydraulic pressure that assists the driver in steering. Our tubes are engineered to ensure smooth, responsive steering, contributing to vehicle safety and driver comfort.

- Heavy-Duty Commercial Vehicles: In applications like tractor-trailers, buses, and municipal vehicles, the steering forces are significantly higher. Our robust tubes handle the elevated pressures and greater dynamic stresses, ensuring precise control and operational longevity for fleets that log millions of miles.

- Construction and Mining Equipment: Excavators, loaders, bulldozers, and mining trucks rely on powerful hydraulic systems not just for steering, but also for operating implements. While the primary keyword specifically refers to "power steering," the underlying technology for hydraulic tubing is shared. Our specialized tubing designs, particularly those with enhanced vibration and corrosion resistance, are adapted for the extreme duty cycles and harsh, abrasive environments common in these sectors, ensuring uninterrupted operation of critical hydraulic lines, including steering assistance circuits.

- Agricultural Machinery: Tractors, harvesters, and other farm equipment operate in diverse terrains and weather conditions, requiring durable hydraulic components. Our tubes are integral to the power steering and auxiliary hydraulic systems, providing reliable performance for demanding tasks and extended field operation.

- Material Handling Equipment: Forklifts, reach trucks, and stackers utilize hydraulic systems for steering and lifting. The reliability of these tubes is critical for operational safety and efficiency in warehousing and logistics environments, minimizing downtime due to hydraulic failures.

In each of these scenarios, the ability of the tube to maintain hydraulic pressure integrity, resist fatigue from vibration and pressure pulsation, and withstand environmental degradation is paramount. Our products are specifically designed to meet these challenges, reducing the total cost of ownership through superior durability and reduced maintenance.

Fig. 2: A High-quality power steering tube installed in a heavy-duty vehicle application.

Technical Advantages and Performance Edge

The inherent advantages of our High-quality power steering tube stem from a combination of advanced material science, precision engineering, and stringent quality control. These advantages translate directly into measurable benefits for our B2B clients, ensuring superior system performance and reduced operational costs.

- Exceptional Durability and Longevity: Engineered from high-tensile steel alloys and subjected to advanced cold-drawing processes, our tubes exhibit superior resistance to material fatigue, pressure pulsations, and external mechanical stresses. This results in an extended service life, significantly reducing the frequency of replacements and associated maintenance costs. Our tubes are designed to outlast typical vehicle lifecycles, ensuring reliable operation for millions of cycles.

- Unrivaled Corrosion Resistance: Utilizing state-of-the-art multi-layer protective coatings, such as zinc-nickel or specialized organic finishes, our tubes offer outstanding protection against environmental aggressors like road salts, moisture, and automotive chemicals. This defense against corrosion is critical for maintaining structural integrity and preventing leaks, especially in regions with harsh winter conditions.

- Precision Fitment and Leak-Proof Integrity: Achieved through advanced CNC bending, accurate end forming, and robust fitting integration, our tubes ensure precise alignment and a secure, leak-free connection within the hydraulic system. This minimizes fluid loss, maintains optimal system pressure, and prevents contamination, which is vital for system efficiency and safety.

- Optimized Flow Characteristics and Efficiency: The smooth internal bore and optimized bend radii, achieved through sophisticated forming techniques, reduce turbulence and pressure drop. This ensures efficient hydraulic fluid flow, contributing to reduced energy consumption by the power steering pump and overall improved system efficiency.

- Superior Vibration Damping and Noise Reduction: Our design considerations and material choices contribute to excellent vibration damping properties, reducing the transmission of noise and vibration through the steering system. This enhances driver comfort and reduces wear on interconnected components.

- Compliance with Global Standards: Our manufacturing processes and products are certified to international standards such as ISO 9001 and IATF 16949 for quality management, and product performance adheres to SAE and ISO specific guidelines. This ensures global compatibility and adherence to the highest benchmarks for automotive components.

These technical advantages collectively position our power steering tubes as a premium choice for manufacturers and operators seeking to enhance the reliability, safety, and performance of their hydraulic steering systems while simultaneously reducing long-term maintenance expenditures.

Vendor Comparison Considerations

Selecting the right supplier for critical components like a High-quality power steering tube involves evaluating various factors beyond just price. B2B decision-makers must consider a holistic range of capabilities to ensure long-term value, reliability, and strategic partnership.

| Factor | Our Offering | Typical Market Offering |

|---|---|---|

| Quality Certifications | IATF 16949, ISO 9001, ISO 14001, relevant SAE/ASTM/EN product standards | Often just ISO 9001, less specific product standard adherence |

| Material Traceability | Full batch-level traceability from raw material to finished product | Limited or batch-only traceability |

| Corrosion Resistance (Salt Spray) | Min. 1000 hours (zinc-nickel plating) | Often 200-500 hours (standard zinc plating) |

| Fatigue & Impulse Testing | > 2 million cycles at working pressure | 1 million cycles or less |

| Internal Cleanliness | ISO 4406 (18/16/13) or better | Less stringent, or not consistently tested |

| Customization Capabilities | Full engineering support for material, geometry, fittings, coatings | Limited to standard configurations |

| After-Sales Support | Dedicated technical support, warranty, field service assistance | Basic support, limited warranty |

Our commitment to exceeding industry benchmarks in each of these areas positions us as a premier partner for manufacturers seeking to optimize the performance and reliability of their power steering systems.

Customized Solutions for Unique Demands

Recognizing that standard components may not always meet the unique requirements of every application, we specialize in providing highly customized solutions for High-quality power steering tube assemblies. Our engineering team collaborates closely with clients from concept to production, ensuring optimal performance and seamless integration.

- Material Optimization: Tailoring tube material (e.g., specific steel alloys, stainless steel grades) to combat extreme temperatures, aggressive chemical exposure, or specialized pressure requirements. For instance, in corrosive marine environments, a duplex stainless steel might be specified instead of standard carbon steel.

- Geometry and Routing Design: Developing complex tube geometries and routings to fit within confined spaces, minimize vibration, and optimize fluid flow. Our advanced CAD/CAM capabilities and simulation tools ensure precise fitment and performance prediction before physical prototyping.

- Specialized Coatings and Finishes: Applying custom coatings for enhanced corrosion protection, electrical insulation, or specific aesthetic requirements. This could include specialized polymer coatings for abrasion resistance or high-temperature ceramic coatings.

- Integrated Fittings and Connectors: Designing and integrating bespoke end fittings, flanges, or quick-connect couplings to interface with unique pump, reservoir, or steering gear configurations. This includes custom thread types, seal designs, and material combinations for specific fluid compatibility.

- Assembly and Kitting: Providing complete assembled solutions, including mounting brackets, clamps, and integration with flexible hose sections, delivered as a pre-tested kit ready for immediate installation on the production line, streamlining client assembly processes.

Our agile manufacturing capabilities and dedicated R&D team are equipped to translate intricate engineering challenges into robust, production-ready power steering tube solutions, adhering to the highest standards of quality and performance.

Application Case Studies

Our expertise in delivering a High-quality power steering tube is validated by successful implementations across various demanding applications. These case studies highlight our commitment to problem-solving and delivering tangible value.

Case Study 1: Heavy-Duty Truck OEM

- Challenge: A major heavy-duty truck manufacturer was experiencing premature power steering tube failures due to severe road salt corrosion and high-frequency vibration in specific geographic regions, leading to increased warranty claims and operational downtime for their fleet customers. Standard tubes offered a maximum of 500 hours of salt spray resistance.

- Solution: We engineered a custom power steering tube solution using a specialized high-strength low-alloy steel combined with a multi-layer zinc-nickel coating. The tube's geometry was also optimized to incorporate additional vibration dampeners. Extensive impulse and vibration testing was performed, exceeding the OEM's specified requirements.

- Result: The new tubes demonstrated over 1,200 hours of salt spray resistance (ASTM B117) and successfully passed 2.5 million impulse cycles. This led to a 75% reduction in power steering tube-related warranty claims within two years of implementation, significantly enhancing fleet reliability and customer satisfaction for the OEM.

Case Study 2: Agricultural Equipment Manufacturer

- Challenge: An agricultural equipment manufacturer needed a more durable and space-efficient power steering tube for a new line of compact tractors. The existing tubes were bulky and prone to damage from field debris, also suffering from internal contamination issues affecting pump longevity.

- Solution: We designed a custom-bent High-quality power steering tube assembly with a reduced bending radius, allowing for tighter packaging within the chassis. We implemented advanced cold-forming techniques to maintain wall thickness and integrity, and ensured ultra-high internal cleanliness standards (ISO 4406 level 18/16/13) through a specialized internal flushing and particulate verification process.

- Result: The new tubes provided a 15% reduction in overall hydraulic system footprint. Field trials showed zero instances of contamination-related pump failures over 3,000 operational hours, and the enhanced routing significantly reduced external damage incidents, leading to improved reliability and reduced repair costs for end-users.

Fig. 3: A completed High-quality power steering tube assembly, ready for installation.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a customized High-quality power steering tube order?

A1: Lead times vary based on complexity, material availability, and order volume. For standard configurations, our lead time typically ranges from 4-6 weeks for production after design approval. For highly customized solutions requiring new tooling or specialized materials, lead times may extend to 8-12 weeks. We offer expedited services for urgent requirements upon consultation.

Q2: What warranty is offered for your power steering tubes?

A2: We stand behind the quality of our products with a comprehensive warranty. Our High-quality power steering tube products come with a 2-year or 50,000-mile (80,000 km) warranty, whichever comes first, against manufacturing defects and material failures under normal operating conditions. Extended warranty options are available for specific applications upon request.

Q3: How do you ensure internal cleanliness for sensitive hydraulic systems?

A3: Our manufacturing process includes multi-stage cleaning, flushing, and drying procedures. We utilize specialized high-pressure fluid flushing and air knife techniques, followed by rigorous particulate testing according to ISO 4406 standards. This ensures that our High-quality power steering tube meets critical cleanliness levels, preventing contamination and extending the life of hydraulic pumps and components.

Q4: Can you accommodate small batch orders for prototyping or specialized vehicles?

A4: Yes, we understand the need for flexibility in R&D and specialized vehicle production. We offer prototyping services and can accommodate small batch orders. Our engineering team works closely with clients to validate designs and production processes, ensuring the same high standards are applied regardless of order volume.

Lead Time, Fulfillment, and Customer Support

Our commitment to our clients extends beyond product quality to encompass efficient logistics and comprehensive after-sales support, ensuring a seamless experience from order to operation.

Lead Time and Fulfillment

We operate with advanced planning systems to optimize material procurement and production scheduling. Typical lead times for our High-quality power steering tube range from 4 to 8 weeks, depending on product complexity, customization requirements, and order volume. We maintain a flexible manufacturing process to respond to fluctuating demands and offer expedited production options for critical projects. Our global logistics network ensures timely and reliable delivery to your facilities worldwide, with options for various shipping methods to meet specific transit time and cost requirements. We provide detailed tracking and proactive communication throughout the fulfillment process.

Warranty Commitments

Each High-quality power steering tube manufactured by us is backed by a robust warranty against defects in materials and workmanship. Our standard warranty covers products for a period of 2 years or 50,000 miles (80,000 km), whichever occurs first, from the date of installation or purchase, provided they are used under normal operating conditions and installed correctly. We are committed to prompt resolution of any warranty claims, ensuring minimal disruption to your operations.

Customer Support

Our dedicated customer support team comprises experienced technical professionals ready to assist with product selection, technical inquiries, installation guidance, and troubleshooting. We offer:

- Technical Assistance: Expert guidance on product specifications, application suitability, and integration challenges.

- Order Management: Real-time updates on order status, shipping, and delivery schedules.

- Field Support: For complex issues, our field engineers can provide on-site diagnostic and support services.

- Training: We can provide product training for your engineering and maintenance teams to ensure optimal handling and installation.

Our goal is to build long-term partnerships by providing not just superior products, but also unparalleled service and support.

Authoritative References

- 1. ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- 2. IATF 16949:2016 - Quality management system for automotive production and relevant service parts organizations. International Automotive Task Force.

- 3. SAE J1401 - Hydraulic Brake Hose Assemblies for Use with Nonpetroleum-Base Hydraulic Fluids. Society of Automotive Engineers.

- 4. ISO 16750-4:2010 - Road vehicles - Environmental conditions and testing for electrical and electronic equipment - Part 4: Climatic loads. International Organization for Standardization.

- 5. ASTM B117 - Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- 6. ISO 4406:2021 - Hydraulic fluid power - Code for cleanliness level by automatic particle counter. International Organization for Standardization.

- 7. EN 10305-1 - Steel tubes for precision applications - Technical delivery conditions - Part 1: Seamless cold drawn tubes. European Standard.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025