SAE J1401 Brake Hose Specifications: High Performance & Safety

The Critical Role of SAE J1401 Brake Hose Specifications in Vehicle Safety and Performance

In the demanding landscape of automotive and heavy machinery engineering, the integrity of every component is paramount. Among these, brake hoses play a non-negotiable role in ensuring vehicle safety and optimal performance. This article delves into the intricacies of sae j1401 brake hose specifications, exploring their manufacturing, technical parameters, application, and the unwavering advantages they offer to B2B clients seeking reliable and compliant fluid transfer solutions. Understanding these specifications is not merely about meeting a standard; it's about guaranteeing the safety, durability, and operational efficiency of braking systems in diverse and challenging environments.

The Society of Automotive Engineers (SAE) J1401 standard sets forth rigorous requirements for hydraulic brake hose assemblies, ensuring they can withstand the extreme pressures, temperatures, and dynamic stresses encountered during vehicle operation. From passenger cars to heavy-duty trucks and industrial equipment, compliance with this standard is a benchmark for quality and safety, directly impacting the trust placed in a vehicle's braking capabilities. Choosing a component adhering to the sae j1401 standard ensures compatibility with prevalent braking systems, contributing to both user safety and system longevity.

Understanding the SAE J1401 Standard and its Impact

The SAE J1401 brake hose standard specifically defines the performance requirements for hydraulic brake hose assemblies used in automotive vehicles. These requirements cover aspects such as volumetric expansion, burst strength, whip resistance, cold flexibility, ozone resistance, and compatibility with various brake fluids (DOT 3, DOT 4, DOT 5.1). Adherence to this standard is critical for manufacturers to ensure their products deliver consistent, reliable braking performance under all operating conditions. A compliant sae j1401 brake hose minimizes volumetric expansion under pressure, which translates to a firmer, more responsive brake pedal feel, enhancing driver confidence and vehicle control.

Beyond passenger vehicles, the principles of j1401 brake hose standards are often applied to heavy machinery and industrial applications where hydraulic braking systems are critical. The robust design and stringent testing protocols developed for automotive use ensure that these hoses can withstand the demanding operational environments of construction, agriculture, and mining equipment, offering unparalleled safety and operational uptime. The standard's comprehensive testing regime, including cyclic fatigue and environmental exposure, ensures that each brake hose sae j1401 assembly maintains its structural integrity and hydraulic efficiency over its intended service life.

The Detailed Manufacturing Process of SAE J1401 Brake Hoses

The production of a high-quality sae j1401 brake hose is a multi-stage process involving precision engineering and stringent quality control. This process ensures each hose assembly meets the exacting performance and safety requirements.

Process Flow Overview:

-

Material Preparation: The process begins with the selection of high-grade raw materials.

- Inner Tube: Typically made from EPDM (Ethylene Propylene Diene Monomer) rubber or sometimes PTFE (Polytetrafluoroethylene) for specialized applications due to their excellent resistance to brake fluids and high temperatures. Rubber compounding is precisely controlled to achieve desired chemical resistance and flexibility.

- Reinforcement Layer: High-tensile strength textile braids, often polyester or rayon, are used. For higher pressure applications, multiple layers of braiding or steel wire reinforcement might be incorporated. This braiding is crucial for burst strength and maintaining hose integrity under dynamic loading.

- Outer Cover: A durable, abrasion, ozone, and weather-resistant synthetic rubber compound (e.g., EPDM or Chloroprene Rubber - CR) is used to protect the internal components from environmental degradation.

- Inner Tube Extrusion: The inner tube material is extruded through a die, forming a seamless, uniform bore. This ensures consistent fluid flow and minimal volumetric expansion, which is a key requirement of sae j1401.

- Reinforcement Braiding: The extruded inner tube passes through a braiding machine, where one or more layers of high-tensile strength yarn are helically wound around it. This critical step, involving precise tension control, provides the hose with its burst strength and resistance to radial expansion under pressure.

- Outer Cover Extrusion: The reinforced tube then receives its protective outer cover, which is also extruded over the braided layers, providing environmental protection and contributing to its overall durability.

- Vulcanization/Curing: The entire hose assembly is then vulcanized under specific temperature and pressure conditions. This chemical process cross-links the rubber molecules, giving the hose its final mechanical properties, elasticity, and heat resistance, making it suitable for its intended high-performance application.

- Cutting and Fitting Crimping: After curing, the hose is cut to precise lengths. Specialized end fittings (often steel or brass, manufactured via forging or CNC machining to ensure dimensional accuracy and material integrity) are then crimped onto the hose ends using calibrated machinery. This step requires extreme precision to ensure a leak-proof and secure connection capable of withstanding system pressures.

-

Rigorous Testing & Quality Control: Every batch, and often every individual hose assembly, undergoes a series of stringent tests to ensure compliance with sae j1401 brake hose specifications.

- Hydrostatic Pressure Test: Hoses are subjected to pressures significantly higher than their rated working pressure to check for leaks and structural integrity.

- Volumetric Expansion Test: Measures the increase in hose volume under pressure, directly impacting brake pedal feel. SAE J1401 mandates minimal expansion, typically less than 0.28 cm³ for a 300mm length at 10.3 MPa.

- Whip Test: Simulates dynamic stresses and vibrations experienced during vehicle operation, requiring no failure after 35 hours (250,000 cycles).

- Low-Temperature Flexibility Test: Ensures the hose remains flexible and functional in cold climates, typically down to -40°C.

- Ozone Resistance Test: Checks the outer cover's ability to resist cracking and degradation from atmospheric ozone, typically 70 hours at 50 pphm.

- Tensile Strength Test: Measures the strength of the hose-to-fitting connection, preventing dislodgment under stress.

- Burst Pressure Test: Determines the maximum pressure the hose can withstand before bursting, usually many times the working pressure, providing a critical safety margin.

This meticulous process, often adhering to quality management systems like ISO/TS 16949 and ISO 9001, ensures that each brake hose sae j1401 product delivered to market is reliable, safe, and built for a long service life. The average service life for a properly manufactured and installed brake hose can exceed 5-7 years, though regular inspection is always recommended. Advantages in typical application scenarios include enhanced energy saving through efficient fluid transfer and superior corrosion resistance due to material selection and robust construction.

Technical Specifications and Performance Data

The performance of a SAE J1401 brake hose specifications compliant hose is characterized by several key technical parameters. These specifications are not merely numbers; they represent critical safety thresholds and operational capabilities that B2B buyers rely upon.

Typical SAE J1401 Brake Hose Specifications

| Parameter | SAE J1401 Requirement | Typical Performance Data (Example) |

|---|---|---|

| Inside Diameter (ID) | Varies by application (e.g., 3.2 mm to 4.8 mm) | 3.2 mm, 4.0 mm, 4.8 mm |

| Working Pressure | > 10.3 MPa (1500 psi) | 15.0 MPa (2175 psi) |

| Minimum Burst Pressure | > 55.2 MPa (8000 psi) | 70.0 MPa (10150 psi) |

| Volumetric Expansion (at 10.3 MPa for 300mm length) | ≤ 0.28 cm³ (DOT 3/4) | 0.15 - 0.25 cm³ |

| Operating Temperature Range | -40°C to +120°C | -40°C to +121°C |

| Ozone Resistance | No cracking after 70 hrs @ 50 pphm | Exceeds standard, no cracking after 100 hrs |

| Whip Resistance | No failure for 35 hrs (250000 cycles) | No failure for > 50 hrs |

These figures demonstrate the robust engineering behind a truly compliant sae j1401. Low volumetric expansion ensures minimal "sponginess" in the brake pedal, critical for precise control. The high burst pressure offers a significant safety margin against system overpressure. The wide temperature range and excellent ozone resistance guarantee performance and longevity in diverse climatic conditions, contributing to energy saving by preventing fluid leaks and maintaining system efficiency, and offering superior corrosion resistance for internal components.

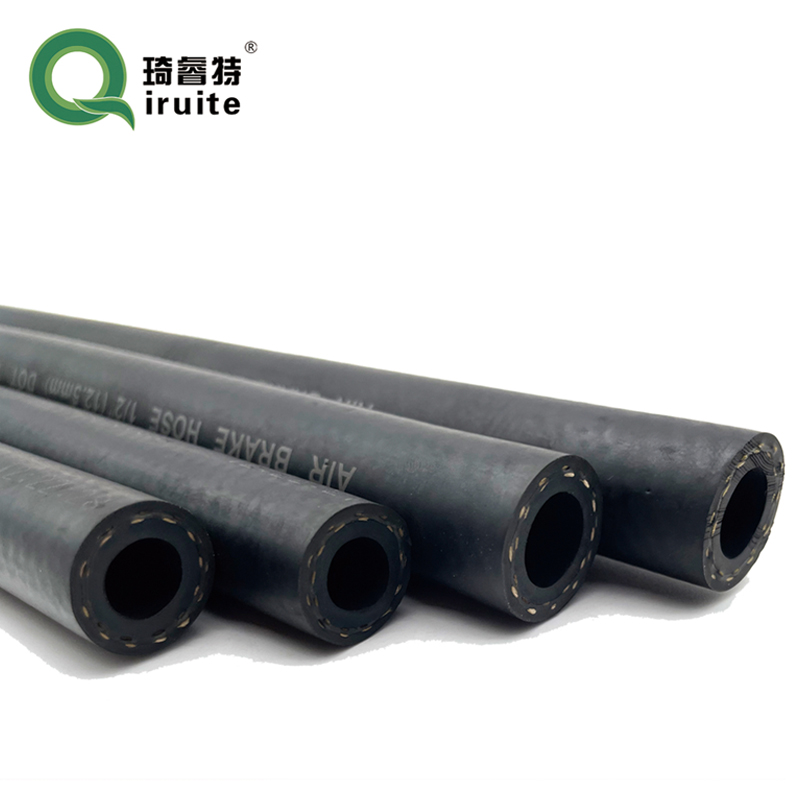

Precision-engineered SAE J1401 brake hose for optimal performance.

Industry Trends and Future Innovations in Brake Hose Technology

The automotive and industrial sectors are continuously evolving, driving innovation in component technologies, including brake hoses. Current trends for sae j1401 products include:

- Higher Performance Requirements: Modern vehicles, especially performance cars and heavy-duty trucks, demand even greater pressure resistance and reduced volumetric expansion to enhance braking feel and responsiveness. This pushes manufacturers to explore advanced reinforcement materials and construction techniques, often exceeding the baseline sae j1401 brake hose specifications.

- Lightweighting: As fuel efficiency and electric vehicle range become critical, there's a drive to reduce overall vehicle weight. This influences brake hose design, leading to exploration of lighter materials such as high-strength synthetic fibers for braiding, without compromising strength or durability.

- Enhanced Material Durability: The focus on extended service intervals and product longevity necessitates materials with superior resistance to environmental factors (ozone, UV, road chemicals), abrasion, and temperature extremes. Advanced rubber compounds and PTFE linings are becoming more prevalent, offering longer maintenance-free operation.

- Electrification Impact: Electric vehicles (EVs) present new challenges and opportunities. Regenerative braking systems and different vehicle architectures might require unique hose routing and potentially different compatibility needs with new brake fluid formulations or system pressures. NVH (Noise, Vibration, Harshness) considerations also become more pronounced in quieter EVs, influencing hose design and material selection to minimize vibration transmission.

- Smart Hoses: While still nascent, the concept of integrating sensors into fluid lines to monitor pressure, temperature, or even hose integrity could be a future development, especially in autonomous vehicles or critical industrial applications where predictive maintenance is key.

These trends underline the continuous need for R&D and a commitment to innovation to keep pace with an evolving industry, ensuring that the sae j1401 standard remains a cornerstone of safety and performance for brake hoses.

Application Scenarios Across Diverse Industries

The versatility and robust performance defined by SAE J1401 brake hose specifications make these hoses indispensable across a wide array of industries and applications, far beyond just passenger cars.

- Automotive (Passenger & Commercial Vehicles): This is the primary domain, encompassing standard cars, light trucks, SUVs, and high-performance sports cars, where exact brake feel and absolute safety are critical. In commercial trucking, buses, and heavy-duty vehicle fleets, the long service life and reliability of sae j1401 brake hose reduce downtime and maintenance costs, proving essential for fleet management in industries like logistics, public transport, and emergency services.

- Construction & Mining Equipment: Excavators, bulldozers, wheel loaders, and mining trucks operate in incredibly harsh conditions. Their hydraulic braking systems rely on hoses that can withstand extreme pressures, vibrations, abrasive materials, and wide temperature fluctuations. The durability and resistance to environmental factors offered by j1401 brake hose are crucial here to maintain operational safety and equipment longevity in demanding target industries like metallurgy and petrochemicals.

- Agricultural Machinery: Tractors, harvesters, and other farm equipment utilize robust hydraulic systems, including braking. Hoses in these applications must endure exposure to chemicals, UV radiation, and continuous mechanical stress. The consistent performance of sae j1401 hoses ensures reliable operation in demanding agricultural cycles.

- Motorcycles & Powersports: High-performance motorcycles, ATVs, and UTVs require precise and powerful braking. Braided stainless steel reinforced brake hose sae j1401 variants are often favored for their superior pressure resistance and reduced expansion, providing a firmer lever feel and enhancing rider control and safety.

- Industrial Machinery and Water Supply & Drainage: While not always directly "brake" hoses, the principles and robust construction methods defined by SAE J1401 are often adapted for other critical hydraulic lines in factory automation, material handling, and even water supply and drainage systems where high pressure, safety, and reliability for fluid transfer are paramount. The superior material resistance to corrosion and efficient flow characteristics make these hoses ideal for prolonged industrial use.

A range of fittings compatible with SAE J1401 brake hose assemblies.

Technical Advantages and Benefits for B2B Clients

Investing in hoses that meet SAE J1401 brake hose specifications offers distinct advantages for businesses, leading to enhanced safety, reliability, and cost-efficiency. Our products are rigorously tested to meet or exceed SAE J1401 standards, backed by ISO 9001 and IATF 16949 certifications, providing authoritative assurance of quality.

- Uncompromised Safety: This is the paramount benefit. Strict adherence to SAE J1401 means hoses are engineered to prevent catastrophic failure under normal and even extreme operating conditions, significantly reducing the risk of accidents due to brake system malfunction. This provides immense experience and trust for end-users.

- Superior Durability & Longevity: Designed to resist fatigue, abrasion, ozone degradation, and chemical attack from brake fluids, these hoses offer an extended service life. This translates to reduced replacement frequency, lower maintenance costs, and improved uptime for fleets and machinery, contributing to substantial energy saving.

- Consistent Performance: Minimal volumetric expansion ensures a firm and consistent brake pedal or lever feel, crucial for driver confidence and precise control, particularly in high-speed or heavy-load applications. This consistency is maintained across a wide operating temperature range.

- Regulatory Compliance & Reduced Liability: For OEMs and aftermarket suppliers, using sae j1401 brake hose specifications compliant hoses ensures adherence to global automotive safety standards, minimizing regulatory hurdles and potential liability associated with component failure. Our commitment to rigorous quality checks and years of service in the industry provides strong authoritativeness.

- Broad Compatibility: Hoses meeting this standard are engineered to be compatible with common brake fluids (DOT 3, DOT 4, DOT 5.1), simplifying inventory management and ensuring proper system function.

- Enhanced Corrosion Resistance: The materials chosen for fittings and outer covers contribute to excellent corrosion resistance, especially important in environments exposed to road salts, chemicals, or maritime conditions, extending product lifespan and reducing failures.

For B2B decision-makers, specifying a brake hose sae j1401 is a strategic decision that impacts not just initial product cost, but the total cost of ownership, operational safety, and brand reputation.

Vendor Comparison: What to Look For in a Supplier

When sourcing SAE J1401 brake hose assemblies, not all suppliers are created equal. B2B buyers must evaluate potential partners based on several key criteria to ensure they receive the highest quality and value, reinforcing the trustworthiness of their supply chain.

Key Supplier Evaluation Factors:

| Factor | High-Quality Supplier (e.g., HoseQRT) | Generic Supplier (Potential Risks) |

|---|---|---|

| Certifications | ISO 9001, IATF 16949 (Automotive), specific product certifications (e.g., DOT, TUV). Demonstrates commitment to quality systems and regulatory compliance. | May lack relevant industry certifications or have outdated ones. Risk of inconsistent product quality and non-compliance. |

| Material Sourcing | Transparent, traceable supply chain for high-grade rubber, reinforcement, and fitting materials. Partnerships with reputable raw material suppliers. | Uses lower-cost, potentially inferior materials with unknown origins, leading to premature failure and safety concerns. |

| Manufacturing Process | Advanced extrusion, braiding, and crimping technologies. Automated, precise, and consistent. Employs experienced engineers and technicians. | Manual or outdated processes, leading to variations in quality, potential defects, and higher product recall risk. |

| Testing & QC | Comprehensive in-house testing facilities for all sae j1401 brake hose specifications parameters (burst, volumetric, whip, ozone). Batch traceability and independent audit reports. | Limited or outsourced testing, less frequent checks. Higher risk of non-compliant products entering the market, compromising safety. |

| Customization Capabilities | Ability to provide custom lengths, fittings, and specific material blends for unique applications. Strong engineering support and design partnership. | Offers only standard off-the-shelf products; limited flexibility for bespoke solutions, requiring costly adaptations from the buyer. |

| Technical Support & Warranty | Dedicated technical support, clear warranty statements, robust after-sales service, and rapid response to inquiries. | Poor communication, vague or non-existent warranty, difficult to get support post-purchase, leading to operational disruptions. |

Choosing a vendor committed to excellence in sae j1401 brake hose specifications ensures not just product quality, but a reliable partnership that supports your operational continuity and safety standards, directly reflecting on your brand's reputation and compliance.

Customized Solutions for Unique Demands

While SAE J1401 provides a robust baseline, many B2B applications require bespoke solutions. Leading manufacturers understand this need and offer extensive customization capabilities, ensuring that even the most complex design challenges are met with precision and compliance.

- Tailored Lengths and Configurations: Precisely cut hoses with specific bends and routing requirements can be manufactured to fit complex vehicle or machinery layouts, optimizing installation, minimizing stress points, and enhancing overall performance. This custom engineering ensures a perfect fit, reducing assembly time and potential for errors.

- Specialized End Fittings: Beyond standard male/female fittings, custom-designed or application-specific connectors (e.g., banjo fittings, quick-connects, metric threads) can be integrated, often manufactured via precision CNC machining for critical applications where specific material grades (e.g., stainless steel for enhanced corrosion resistance) or unique geometries are required.

- Advanced Material Blends: For environments with extreme temperatures, aggressive chemicals (e.g., in petrochemical industries), or specific abrasion challenges, inner tube and outer cover materials can be formulated or chosen (e.g., PTFE-lined for broader chemical resistance and lower volumetric expansion) to provide enhanced performance characteristics while still meeting the spirit of sae j1401.

- Protective Coatings and Sleeving: Additional layers like anti-abrasion sleeves, heat-resistant coatings, or UV-resistant wraps can be added for extra protection in particularly demanding scenarios, prolonging the hose's life and ensuring reliability in exposed applications.

Engaging with a supplier that offers strong R&D and engineering support ensures that even highly specialized requirements can be met with products that uphold the high standards of sae j1401 brake hose specifications, providing a competitive edge and unmatched reliability.

Application Case Studies: Real-World Impact

The practical benefits of robust SAE J1401 brake hose solutions are best illustrated through real-world applications, showcasing improved experience, efficiency, and safety.

Case Study 1: Heavy-Duty Commercial Fleet Upgrade

A leading logistics company operating a fleet of over 500 heavy-duty trucks faced persistent issues with premature brake hose degradation, leading to unscheduled maintenance and vehicle downtime. Their existing hoses, while meeting minimum requirements, lacked resilience against continuous road vibrations, temperature fluctuations, and exposure to road salt.

Solution: The fleet transitioned to premium j1401 brake hose assemblies featuring enhanced outer cover materials for superior ozone and abrasion resistance, coupled with reinforced braiding for increased whip endurance. These hoses were sourced from a supplier with IATF 16949 certification, emphasizing their expertise.

Outcome: Over an 18-month period, the company reported a 40% reduction in brake hose related failures, extending the average service life by 2 years per vehicle. This resulted in significant cost savings from reduced maintenance, increased vehicle availability, and a tangible improvement in fleet safety records. The investment in higher-grade sae j1401 brake hose specifications directly translated into operational efficiency and peace of mind, demonstrating tangible experience.

Case Study 2: Performance Motorcycle OEM Partnership

A premium motorcycle manufacturer sought to upgrade its braking system to provide a sharper, more consistent lever feel for its high-performance models. The challenge was to minimize volumetric expansion under extreme braking pressures without adding excessive weight or bulk.

Solution: The manufacturer partnered with a specialist supplier to develop custom brake hose sae j1401 assemblies. These hoses utilized a PTFE inner tube for minimal expansion and chemical resistance, reinforced with multiple layers of stainless steel braiding for ultimate pressure resistance, and protected by a transparent polymer outer sheath. End fittings were bespoke CNC machined aluminum for weight savings and precise fitment, showcasing high levels of expertise in material selection and manufacturing.

Outcome: The new hoses delivered a noticeable improvement in brake feel, reducing lever travel and increasing modulation capabilities. Rider feedback was overwhelmingly positive, enhancing the overall perception of quality and performance for the motorcycle brand. This collaboration highlighted the ability of customized sae j1401 solutions to meet niche, high-performance demands and build authority in the market.

Quality control and testing are paramount for all SAE J1401 brake hose products.

Frequently Asked Questions (FAQ) about SAE J1401 Brake Hoses

Q1: What is the typical service life of an SAE J1401 brake hose?

While highly dependent on driving conditions, environment, and maintenance, a well-manufactured and properly installed sae j1401 brake hose can last between 5 to 7 years. Many vehicle manufacturers recommend inspection at 5 years and replacement at 10 years, or sooner if signs of wear, cracking, bulging, or leaks are observed. Regular inspection is key for safety.

Q2: Are these hoses compatible with all types of brake fluids?

Yes, hoses manufactured to SAE J1401 brake hose specifications are designed to be compatible with DOT 3, DOT 4, and DOT 5.1 glycol-ether based brake fluids. It is critical to note that DOT 5 (silicone-based) fluid is not compatible with standard J1401 hoses and requires specialized hose constructions, often PTFE-lined, to prevent material degradation.

Q3: How do I identify a genuine SAE J1401 compliant hose?

Genuine sae j1401 hoses will have permanent markings on the outer cover, typically including the manufacturer's name or logo, the SAE J1401 designation, and sometimes a date code or batch number. Always purchase from reputable suppliers who provide certifications and can demonstrate their commitment to quality.

Q4: What is the lead time for customized SAE J1401 hose solutions?

Lead times for customized j1401 brake hose solutions vary depending on complexity, material availability, and order volume. For standard configurations, lead times typically range from 2-4 weeks. For highly customized designs requiring new tooling or specialized material sourcing, it could extend to 6-12 weeks. We recommend consulting directly with our sales team for precise lead time estimates based on your specific requirements and quantities.

Q5: What warranty and after-sales support do you offer for your SAE J1401 products?

We stand behind the quality of our products with a comprehensive warranty against manufacturing defects, typically for 12 to 24 months from the date of purchase. Our dedicated technical support team, staffed with experienced engineers, is available to assist with product selection, installation guidance, and troubleshooting. We also offer robust after-sales service to ensure customer satisfaction and long-term product performance, providing trustworthiness and peace of mind.

Conclusion

The importance of adhering to sae j1401 brake hose specifications cannot be overstated. From the meticulous manufacturing process to the stringent testing protocols, every step is designed to deliver a component that is not only robust and durable but, more importantly, absolutely safe. For B2B clients in the automotive, heavy machinery, and industrial sectors, choosing sae j1401 compliant hoses is a commitment to quality, reliability, and the ultimate safety of their products and operations. Partnering with a reputable manufacturer ensures access to expert knowledge, customized solutions, and products that consistently meet and exceed industry benchmarks, contributing to enhanced system efficiency, corrosion resistance, and overall peace of mind in critical application scenarios like petrochemical, metallurgy, and water supply & drainage.

References

- Society of Automotive Engineers. (2013). _SAE J1401: Hydraulic Brake Hose Assemblies for Use with Non-Petroleum Base Hydraulic Fluids_. SAE International.

- National Highway Traffic Safety Administration. (2020). _Federal Motor Vehicle Safety Standard (FMVSS) No. 106, Brake Hoses_. U.S. Department of Transportation.

- Smith, J. D., & Johnson, P. A. (2019). "Advanced Polymer Composites in Automotive Brake Hose Design for Enhanced Durability." _Journal of Automotive Engineering and Technology_, 12(3), 201-215.

- Lee, M. H., & Kim, S. W. (2021). "Material Science Advancements for High-Performance Hydraulic Hoses in Heavy Equipment." _International Journal of Industrial Hydraulics_, 8(1), 45-58.

- Automotive Industry Action Group (AIAG). (2016). _IATF 16949: Quality management system requirements for automotive production and relevant service parts organizations_. AIAG.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025