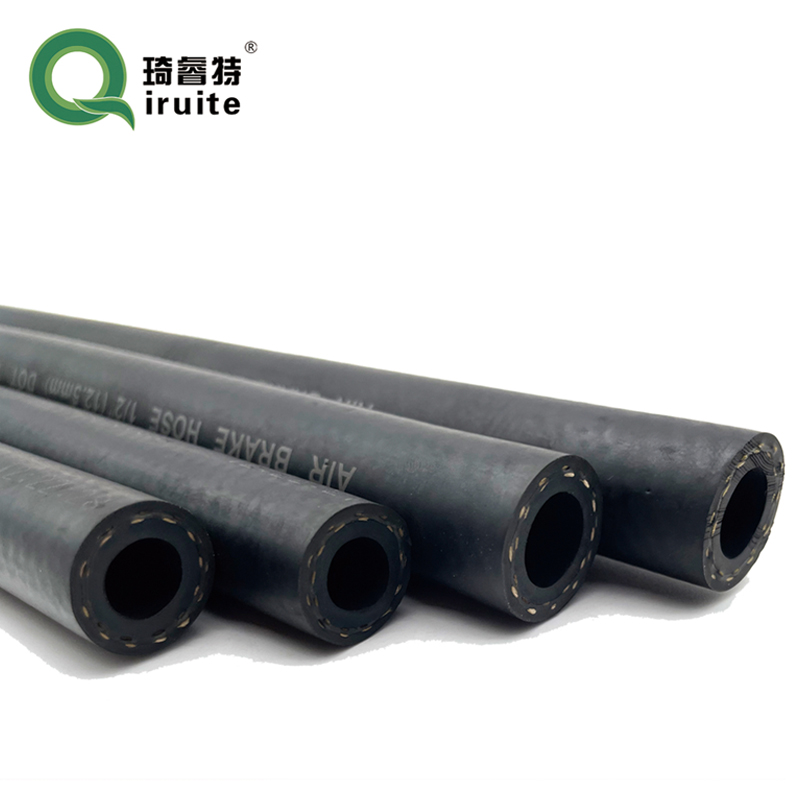

SAE J1401 Brake Hose Specifications: Durable, DOT—Why Us?

Field Notes on sae j1401 brake hose specifications from a Shop-Floor Perspective

I’ve walked more than a few hose lines—from Ningjin County, Hebei Province to the Tier-1 plants in the Midwest—and I can tell you: the quiet hero of a stable pedal feel is the humble SAE J1401 Brake Hose. It’s not glamorous, but when it’s wrong, everybody knows. This Oil brake hose (yes, the older slang still pops up) is tasked with clean, repeatable pressure transmission for auto, truck, and trailer hydraulic braking. And, to be honest, real-world performance usually comes down to materials, braiding discipline, and test culture.

What’s inside the hose (and why it matters)

This SAE J1401 Brake Hose uses an EPDM-based inner tube with a high-tenacity braided reinforcement—typically polyester or nylon—plus an EPDM cover that resists ozone and road splash. The polyester/nylon choice is not cosmetic: polyester brings predictable elongation under pressure, nylon adds toughness. Many customers say the pedal feel is “stabler” when the braid pick count is tight and consistent. It seems that small compounding tweaks (think plasticizer balance) can make low-temp flexibility noticeably better, especially for fleets in colder regions.

Process flow (shop shorthand)

- Material prep: EPDM compounding, moisture-controlled yarn conditioning.

- Inner tube extrusion: concentricity checks every roll change.

- Braiding: polyester/nylon braid with monitored pick per inch (PPI).

- Cover extrusion and vulcanization: stable cure curve, ozone-resist additives.

- Cutting/assembly: fittings crimped to FMVSS 106 methods where applicable.

- Testing: hydrostatic, whip, low-temp flexibility, burst, and ozone resistance per SAE J1401.

Spec snapshot (quick reference)

| Construction | EPDM inner + braided polyester/nylon + EPDM cover |

| Common ID | ≈ 3.2 mm (1/8"), other sizes available |

| Temp range | around −40°C to +120°C (short peaks may vary by compound) |

| Standards | sae j1401 brake hose specifications, FMVSS 106 (assemblies), RoHS; plant-level IATF/ISO as applicable |

| Pressure/burst | Validated per SAE J1401 test protocols; factory targets are set to meet or exceed standard; real-world use may vary |

| Min bend radius | ≈ 50 mm (size- and construction-dependent) |

| Service life | Fleet experience often 5–7 years; environment and routing dominate outcomes |

Applications and feedback

Use cases: passenger cars, light trucks, trailers, and some motorcycles. In retrofit programs, technicians like the consistent crimp bite and low weep on brake fluid. One buyer joked that warranty claims “went quiet,” which is the nicest compliment in braking.

Testing and certifications (the non-negotiables)

- Whip/fatigue, burst, low-temp flexibility, ozone, permeability per sae j1401 brake hose specifications.

- Assemblies validated to FMVSS 106 where required.

- Typical plant certs: IATF 16949 for automotive QMS; ISO 14001 for environmental management.

- Sample lab summary (illustrative): whip test—pass; ozone—no cracks; hydrostatic hold—pass.

Vendor landscape (quick comparison)

| Vendor | Key certification | Avg burst (lab) | MOQ | Lead time | Customization |

|---|---|---|---|---|---|

| QRT (Ningjin, Hebei) | IATF 16949 (plant-level) | Meets/exceeds SAE J1401 (data on file) | Flexible | ≈ 2–4 weeks | ID/OD, braid, lengths, branding |

| Vendor B (Global) | IATF 16949 | Per standard | Medium | 3–6 weeks | Standard catalog |

| Vendor C (Regional) | ISO 9001 | Per standard | Low | ≈ 4–8 weeks | Limited |

Customization playbook

For fleets and OE projects, we usually tweak inner diameter, braid yarn (polyester vs. nylon), cover color/print, and assembly lengths. Routing templates and bend-radius audits up front save headaches later.

Short case note

A trailer OEM running winter routes swapped to a nylon-braid spec from Ningjin-based QRT. Result? Better low-temp flex and fewer weep checks at PDI. Not dramatic, just quietly effective—exactly what you want in brakes.

References

- SAE International: J1401—Road Vehicle—Hydraulic Brake Hose Assemblies—Nonmetallic Materials.

- U.S. NHTSA: FMVSS No. 106—Brake Hoses.

- IATF 16949:2016—Quality management system for automotive production.

- ISO 14001: Environmental management systems.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025