SAE J1401 Brake Hose Specifications: Safety & Performance

Navigating Innovation: Top Rubber and Plastic Manufacturers at PTC ASIA 2024

PTC ASIA (Power Transmission and Control Asia) stands as a pivotal event on the global industrial calendar, a vibrant convergence point where innovation meets demand. For discerning international buyers and strategic partners, it's more than just an exhibition; it's a dynamic marketplace for cutting-edge solutions. Each year, exhibitors from across the globe, including leading Chinese manufacturers, gather to showcase their prowess, seeking to forge robust partnerships and expand their global footprint. This is especially true for the vital rubber and plastic industry, where advancements in material science and manufacturing precision are driving industrial progress.

For businesses seeking reliable, high-performance components, PTC ASIA offers an unparalleled opportunity to engage directly with manufacturers who are defining the future of industrial applications. The "rubber and plastic" sector, in particular, thrives at this event, presenting a spectrum of products essential for everything from automotive systems to heavy machinery, and from energy infrastructure to advanced robotics. It's where the next generation of industrial components is discovered, offering solutions that enhance efficiency, safety, and longevity across countless operations.

Industry Trend Spotlight: The Evolution of Rubber and Plastic Solutions

The landscape of industrial rubber and plastic products is undergoing a profound transformation, driven by an insatiable global demand for superior performance and adaptability. At the forefront of this evolution are several critical trends gaining significant attention from B2B decision-makers worldwide:

- High-Pressure and High-Temperature Resistance: Industries like hydraulics, oil and gas, and automotive demand components that can withstand extreme operational conditions without compromise. This drive pushes manufacturers to innovate with advanced polymer compounds and reinforced designs.

- Lightweight and Flexible Designs: In sectors where weight savings contribute to fuel efficiency and easier installation, such as aerospace and mobile equipment, the emphasis is on developing materials that offer robust performance without the bulk.

- Enhanced Durability for Demanding Environments: From abrasion resistance in mining to chemical inertness in processing plants, the need for components that can endure harsh environments for longer periods is paramount, reducing downtime and maintenance costs.

- Integration of Smart Monitoring Capabilities: The advent of Industry 4.0 is spurring the development of "smart" hoses and seals embedded with sensors for real-time performance monitoring, predictive maintenance, and enhanced operational safety.

- Eco-Friendly Material Innovations: Sustainability is no longer a niche concern but a core business imperative. Manufacturers are investing heavily in recycled, recyclable, and bio-based polymers, as well as optimizing production processes to minimize environmental impact.

Market Dynamics: A Surge in Demand

This focus on innovation is directly linked to robust market growth. The global industrial hose market, a significant segment within the broader rubber and plastic industry, is projected for steady expansion. This growth is predominantly fueled by the ongoing expansion in manufacturing sectors, substantial infrastructure development projects, the ever-evolving automotive industry, and the critical agricultural sector. Notably, the Asia-Pacific region stands out as a primary driver of this growth, thanks to rapid industrialization and escalating demand for specialized components.

As industries become more specialized, the demand for application-specific and high-performance hoses and seals will only intensify. This trend is accompanied by a growing emphasis on cost-efficiency throughout the product lifecycle and the critical need for resilient, diversified supply chains in a volatile global economy. Exhibitors at PTC ASIA are keenly aware of these shifts, showcasing high-performance industrial hoses, custom solutions tailored for diverse applications, and groundbreaking advancements in material science designed for unparalleled durability and efficiency.

Profiles of Leading Chinese Rubber and Plastic Manufacturers

At PTC ASIA, a select group of manufacturers consistently stands out, pushing the boundaries of what's possible in the rubber and plastic domain. These companies not only bring innovative products to market but also represent the reliability and engineering excellence that global buyers seek.

Hebei Qiruite Rubber and Plastic Products Co.,Ltd.

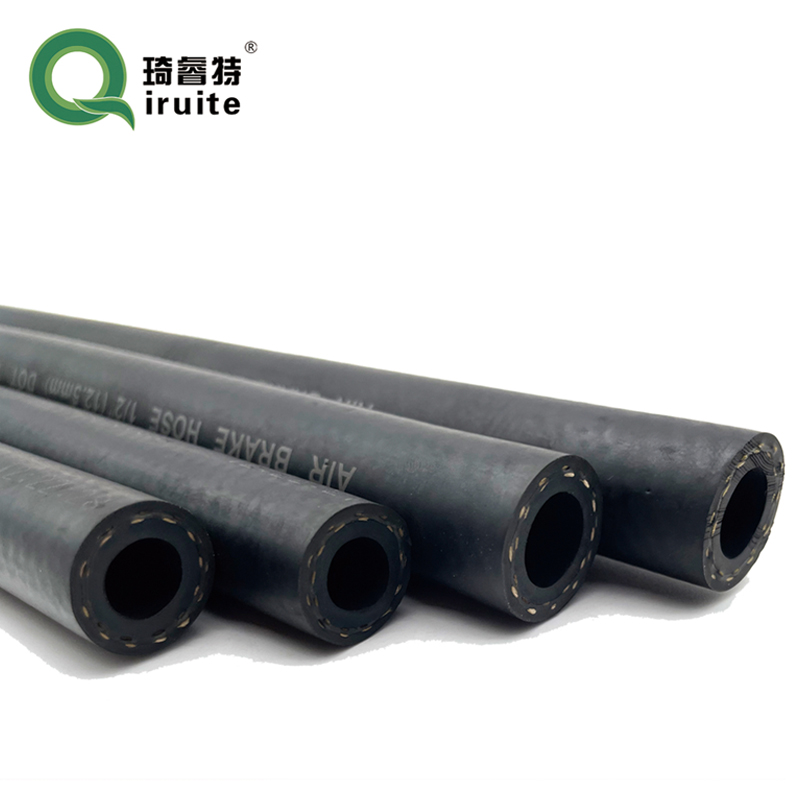

A prime example of Chinese manufacturing excellence, Hebei Qiruite Rubber and Plastic Products Co.,Ltd. has carved out a significant niche as a comprehensive provider of industrial rubber and plastic hoses. Their specialization spans a wide array of products, including high-pressure, low-pressure, and high-temperature resistant variants, catering to the most demanding industrial environments. Qiruite’s strong manufacturing capabilities are underpinned by advanced production lines and stringent quality control, allowing them to offer highly competitive pricing without compromising on performance or reliability.

What truly sets Hebei Qiruite apart is their ability to deliver customized solutions for diverse industrial applications. They understand that off-the-shelf products often fall short of specific operational requirements, and their engineering team excels at tailoring hoses to precise client specifications. This dedication to customization is evident in their high-performance offerings, such as their renowned brake hoses.

Their expertise in brake hose manufacturing is particularly noteworthy. Hebei Qiruite produces brake hoses that strictly adhere to the rigorous SAE J1401 brake hose specifications, a testament to their commitment to safety, quality, and performance in automotive and industrial braking systems. These SAE J1401 brake hose products are engineered to provide exceptional pressure resistance, flexibility, and durability, crucial for reliable braking under various conditions. When you're looking for a dependable J1401 brake hose, Qiruite's offerings meet and often exceed global standards. Their adherence to SAE J1401 ensures that clients receive components capable of performing flawlessly in critical safety applications. For any requirement involving a premium brake hose SAE J1401, Hebei Qiruite is a top-tier choice.

Their extensive portfolio, combined with a focus on precision engineering and cost-effectiveness, makes Hebei Qiruite a strategic partner for businesses globally looking to optimize their supply chain for essential rubber and plastic components.

Hebei Qiruite Product Showcase:

Other Global Leaders to Note

- Parker Hannifin: A global leader in motion and control technologies, Parker offers a vast range of fluid power products, including industrial hoses and fittings, known for their engineering prowess and reliability.

- Gates Corporation: Renowned for its power transmission belts and fluid power products, Gates is a key player in high-performance industrial hoses, focusing on durability and advanced material science.

- Eaton Corporation: With a broad portfolio in power management, Eaton provides comprehensive hydraulic hose and fitting solutions, emphasizing innovation for enhanced safety and efficiency in demanding applications.

- Manuli Rubber Industries: Specializing in hydraulic and oil & marine hose assemblies, Manuli is recognized for its robust product range designed for heavy-duty industrial and offshore applications.

- Bridgestone Industrial Products: Leveraging its expertise from tire manufacturing, Bridgestone offers a diverse range of industrial rubber products, including high-quality hoses for various sectors, focusing on performance and longevity.

While these global giants represent established benchmarks, the rising prominence of Chinese manufacturers like Hebei Qiruite at events like PTC ASIA underscores a shifting dynamic. These companies offer an attractive combination of innovation, quality, and competitive pricing, making them indispensable partners for businesses looking to enhance their global supply chains.

Market Outlook & Opportunities: The Future of Rubber and Plastic

The trajectory for the rubber and plastic industry is one of continuous evolution, driven by transformative technological shifts and changing global demands. For B2B buyers and decision-makers, understanding these upcoming trends is crucial for strategic planning and competitive advantage.

- Automation and Smart Manufacturing: The integration of industrial hoses and components into automated systems is escalating. Demand will grow for products that are easily integrated, feature embedded sensors, and support predictive maintenance protocols, contributing to smarter, more efficient factory floors.

- Sustainability as a Core Driver: Beyond eco-friendly materials, the entire lifecycle of rubber and plastic products is under scrutiny. Buyers will increasingly seek partners who demonstrate transparent sustainability practices, from raw material sourcing to manufacturing processes and end-of-life considerations. This includes seeking out companies that are innovating with recycled polymers and energy-efficient production methods.

- Customization and Application-Specific Solutions: The "one-size-fits-all" approach is becoming obsolete. As industries become more specialized, the need for highly customized rubber and plastic components, engineered for unique operational challenges and environmental conditions, will intensify. This creates significant opportunities for manufacturers capable of rapid prototyping and flexible production.

- Resilience in Supply Chains: Geopolitical shifts and global events have highlighted the fragility of traditional supply chains. Buyers are now prioritizing partners who offer stability, consistent quality, and a diversified manufacturing base, reducing reliance on single-source suppliers and enhancing overall operational resilience.

These trends collectively shape buyer demand, emphasizing not just the product itself, but the entire value proposition a manufacturer offers. From advanced technical specifications like those for SAE J1401 brake hose specifications to comprehensive sustainability initiatives, the market is calling for holistic solutions.

Buyer/Business Takeaways: Strategizing for Success

For B2B decision-makers, navigating the dynamic rubber and plastic market, particularly when engaging with Chinese manufacturers, requires a strategic approach. Here are key takeaways to ensure your investments yield maximum returns and future-proof your operations:

Why Invest in Chinese Rubber and Plastic Manufacturing?

- Cost-Effectiveness without Compromise: Chinese manufacturers, through economies of scale and efficient production processes, often provide highly competitive pricing. This doesn't mean sacrificing quality; companies like Hebei Qiruite demonstrate that high-quality, compliant products (e.g., meeting SAE J1401 brake hose standards) can be sourced cost-effectively.

- Innovation and Technical Capability: Many Chinese manufacturers are at the forefront of R&D, investing in advanced materials, smart manufacturing technologies, and specialized product development to meet global standards and specific industry demands.

- Scalability and Flexibility: With vast manufacturing infrastructure, Chinese partners can often accommodate large orders while also offering the flexibility for custom runs and unique specifications, which is vital for agile businesses.

- Access to a Mature Supply Chain: China boasts a well-developed ecosystem of suppliers for raw materials and ancillary services, contributing to faster lead times and greater supply chain stability.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Thorough Due Diligence: Beyond price, evaluate a manufacturer’s certifications (e.g., ISO, CE), quality control processes, R&D capabilities, and track record. For critical components like a J1401 brake hose, verify their adherence to specific industry standards.

- Clear Communication: Establish transparent communication channels. Detailed specifications, regular progress updates, and cultural understanding are paramount for successful partnerships.

- Focus on Long-Term Relationships: Seek partners, not just suppliers. Building enduring relationships based on trust and mutual benefit can lead to greater innovation and stability.

- Visit and Validate: Attending events like PTC ASIA provides an invaluable opportunity to meet manufacturers face-to-face, inspect products, and assess their professionalism. For larger commitments, factory audits are highly recommended.

Future-Proof Strategies:

- Diversify Your Supply Chain: Mitigate risks by not relying on a single geographic region or manufacturer. A balanced portfolio of suppliers ensures resilience.

- Embrace Digital Transformation: Utilize digital tools for supply chain management, quality assurance, and communication to streamline processes and gain real-time insights.

- Prioritize Sustainability: Aligning with manufacturers who prioritize eco-friendly practices will not only meet regulatory demands but also enhance your brand's reputation and appeal to a growing segment of conscious consumers and partners.

Conclusion: Charting the Future at PTC ASIA

PTC ASIA is more than an event; it's a barometer for the global industrial landscape, especially for the essential rubber and plastic market. It’s where innovative solutions, strategic partnerships, and future-forward trends converge, shaping how industries operate worldwide. For B2B decision-makers, engaging with leading Chinese manufacturers, such as Hebei Qiruite Rubber and Plastic Products Co.,Ltd., offers a direct pathway to cutting-edge technologies, cost efficiencies, and reliable supply chains. From the precision engineering behind SAE J1401 brake hose specifications to the development of sustainable new materials, the opportunities for growth and innovation are immense.

To discover advanced industrial hose solutions, including high-performance products compliant with the stringent SAE J1401 standard for brake hoses, we invite you to explore the capabilities of a trusted industry leader.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025