SAE J2064 Type C Hoses: Premium AC Performance

Understanding SAE J2064 Type C: A Critical Component in Modern AC Systems

In the intricate world of automotive air conditioning, the integrity and performance of every component are paramount. Among these, the flexible hose assemblies play a pivotal role in ensuring efficient refrigerant circulation and system longevity. Specifically, sae j2064 type c specifies the requirements for refrigerant hose assemblies used in mobile air conditioning systems, designed to withstand the rigors of automotive environments while maintaining optimal refrigerant containment. This standard is crucial for manufacturers aiming to meet stringent performance, safety, and environmental regulations.

The specification covers multi-layered hoses that are engineered for low permeation rates and high resistance to vibration, pressure, and temperature fluctuations. It represents a commitment to advanced material science and manufacturing precision, ensuring reliable operation for automotive OEMs and the aftermarket alike. Adherence to sae j2064 ensures that hoses are compatible with modern refrigerants and lubricants, preventing leaks and system degradation over their operational lifespan.

Industry Trends Shaping Automotive AC Hose Technology

The automotive industry is in a state of rapid evolution, with significant trends directly impacting the design and requirements for components like the sae j2064 hose. Key trends include:

- Refrigerant Transition: The global phase-down of R-134a in favor of lower GWP (Global Warming Potential) refrigerants like R-1234yf has necessitated new material formulations and barrier technologies for hoses to maintain low permeation rates. This directly influences specifications under sae j2064.

- Electrification of Vehicles (EVs): Electric vehicles introduce new thermal management challenges. AC systems in EVs often handle both cabin cooling and battery thermal management, requiring hoses that can operate reliably under different temperature profiles and potentially higher pressures.

- Lightweighting: To improve fuel efficiency and extend EV range, there's a constant drive for lighter components. Hose manufacturers are exploring advanced composites and thinner wall constructions that meet or exceed j2064 standards while reducing weight.

- Increased Durability & Lifespan: Consumers expect vehicles to last longer, which translates to a demand for AC components, including sae j2064 air conditioning hose, with enhanced resistance to environmental factors, vibration, and chemical degradation.

These trends underscore the importance of continuous innovation and strict adherence to standards like sae j2064 pdf documentation to ensure future-proof AC system performance.

Technical Specifications and Performance Parameters

Hoses conforming to sae j2064 type c are specifically engineered with a multi-layer construction to achieve superior performance characteristics. This typically includes an inner liner, a barrier layer, reinforcement layers, and an outer cover.

- Inner Liner: Often made from a synthetic rubber blend (e.g., EPDM or IIR), designed for chemical compatibility with refrigerants and oils.

- Barrier Layer: Crucial for preventing refrigerant permeation. Materials like nylon (PA) or polyester (PET) are commonly used to meet strict permeation limits. For instance, sae j2064 type c class ii specifies even lower permeation rates for enhanced environmental protection.

- Reinforcement Layer: Textile braids (e.g., polyester) or spirals provide the necessary burst strength and resistance to vacuum collapse.

- Outer Cover: Typically EPDM, offering excellent resistance to ozone, UV, abrasion, and chemicals found in the engine bay.

Key Performance Parameters (Typical for SAE J2064 Type C)

| Parameter | Typical Specification | SAE J2064 Standard |

|---|---|---|

| Working Pressure | 35-45 bar (500-650 psi) | Min. Burst Pressure (5x working) |

| Burst Pressure | >200 bar (3000 psi) | Min. 175 bar (2500 psi) |

| Operating Temperature Range | -40°C to +135°C (-40°F to +275°F) | -30°C to +125°C (Min) |

| Permeation Rate (R-134a) | Max 3.0 kg/m²/year | Max 3.0 kg/m²/year |

| Permeation Rate (R-1234yf) | Max 4.0 kg/m²/year (Often lower in practice) | Max 4.0 kg/m²/year |

| Vacuum Resistance | Resists collapse under full vacuum | Meets specific collapse criteria |

Note: Specific values may vary by manufacturer and hose diameter but must meet or exceed SAE J2064 minimums.

The Advanced Manufacturing Process of SAE J2064 Type C Hoses

The production of high-performance hoses conforming to sae j2064 type c is a sophisticated multi-stage process, demanding precision engineering and rigorous quality control. The general flow ensures material integrity, structural robustness, and long-term durability.

Process Flow Overview:

1. Material Preparation

Sourcing and compounding of high-quality EPDM, Nylon/PA, and reinforcement fibers.

2. Inner Tube Extrusion

Precise extrusion of the inner rubber liner, ensuring consistent diameter and wall thickness.

3. Barrier Layer Application

Extrusion or application of the critical PA or PET barrier layer over the inner tube.

4. Reinforcement Braiding

Textile braiding (e.g., polyester) provides structural integrity and pressure resistance.

5. Outer Cover Extrusion

Application of the protective EPDM outer cover for environmental resistance.

6. Vulcanization (Curing)

Heating process that cross-links rubber polymers, providing elasticity and durability.

7. Testing & Quality Control

Comprehensive testing including burst pressure, permeation, impulse, and vibration tests.

8. Cutting & Assembly

Hoses cut to length, fittings crimped, and final assemblies checked for leaks.

This meticulous process ensures that the finished sae j2064 type c hose delivers superior performance, extended service life (typically 8-10 years under normal operating conditions), and compliance with international standards such as ISO 9001 and IATF 16949 for automotive quality management.

Target Industries: Primarily the automotive sector, including passenger vehicles, light trucks, heavy-duty trucks, and off-highway vehicles. These hoses are critical for OEMs manufacturing air conditioning systems and for the aftermarket service and replacement industry.

Demonstrated Advantages: Energy saving through minimized refrigerant loss, exceptional corrosion resistance due to robust outer cover, and superior vibration dampening which extends the life of other AC components.

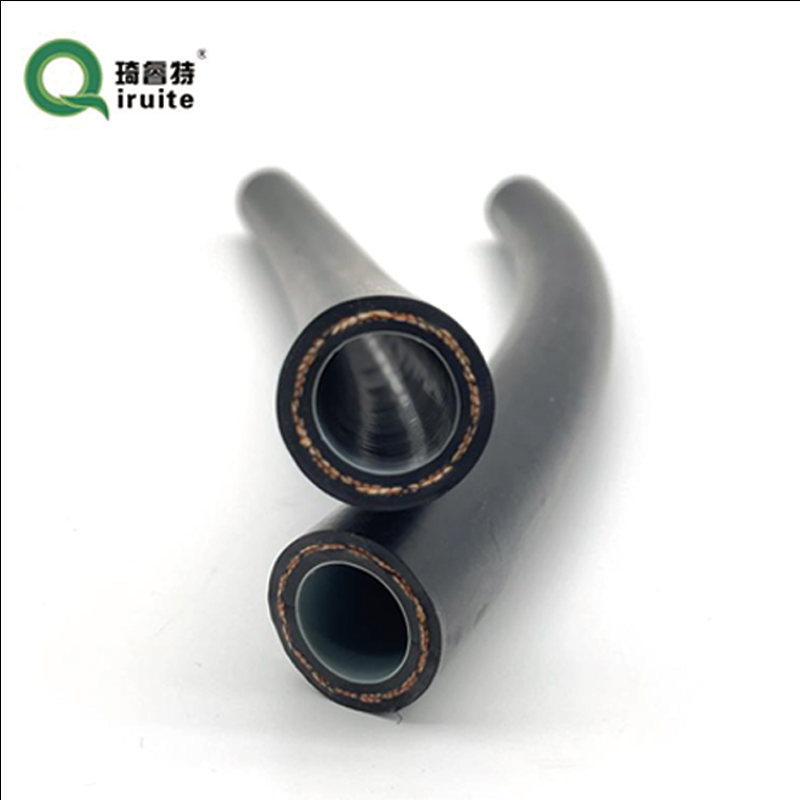

Figure 1: Cross-section of a multi-layer SAE J2064 compliant hose showing robust construction.

Application Scenarios and Operational Advantages

The versatility and robust performance of sae j2064 type c hoses make them indispensable across a wide array of mobile AC applications:

- Passenger Cars & Light Commercial Vehicles: Standard equipment for both suction and discharge lines, providing reliable performance in a dynamic engine bay environment.

- Heavy-Duty Trucks & Buses: Essential for larger AC systems that operate under more extreme conditions and require higher volume refrigerant transfer. The durability and vibration resistance are particularly critical here.

- Off-Highway Equipment: Used in construction machinery, agricultural vehicles, and mining equipment where hoses are exposed to severe abrasion, impact, and temperature fluctuations.

- Electric & Hybrid Vehicles: Adapted for thermal management circuits for batteries and power electronics, demanding specialized configurations and often higher electrical insulation properties in addition to refrigerant handling.

- Aftermarket & Service: Crucial for replacement parts, ensuring that repairs meet OEM performance standards and maintain system efficiency.

Operational Advantages:

- Superior Permeation Control: Minimizes refrigerant leakage, reducing environmental impact and the need for frequent recharges, leading to long-term cost savings.

- Exceptional Durability: High resistance to ozone, UV radiation, heat, and automotive chemicals ensures a longer service life, reducing maintenance intervals.

- Vibration & Flex Fatigue Resistance: Engineered to withstand constant engine vibration and flexing, preventing fatigue cracks and premature failure.

- Broad Refrigerant Compatibility: Designed for optimal performance with current and next-generation refrigerants, including R-134a and R-1234yf.

- Cost-Effectiveness: While initial material costs might be higher than non-compliant alternatives, the extended service life and reduced warranty claims offer significant long-term value.

Vendor Landscape and Product Comparison

The market for automotive AC hoses is competitive, with several reputable manufacturers offering sae j2064 compliant products. While all must meet the baseline SAE standards, differentiation often arises from material innovations, manufacturing precision, and value-added services.

Product Comparison: SAE J2064 Type C vs. Type E

Understanding the nuances between different types within the standard is crucial. For example, sae j2064 type e refers to hoses with an EPDM outer cover and typically a polyamide (nylon) barrier layer, offering excellent permeation resistance and ozone protection. Type C generally implies a similar high-performance multi-layer construction, often with specific requirements for wall thickness and bend radius for compact routing. Manufacturers often tailor these types to specific OEM needs.

| Feature/Parameter | Standard Type C Hose (Typical) | Premium Type C (Enhanced) | SAE J2064 Type E Hose (Common) |

|---|---|---|---|

| Inner Liner Material | IIR/EPDM blend | Optimized IIR/EPDM | IIR/EPDM blend |

| Barrier Layer Material | PA (Nylon) | Co-extruded PA/EVOH blend | PA (Nylon) |

| Outer Cover Material | EPDM | High-grade EPDM with enhanced UV/Ozone | EPDM |

| R-1234yf Permeation | ~4.0 kg/m²/year | ~2.5 kg/m²/year | ~3.5 kg/m²/year |

| Max. Operating Temp. | 135°C (275°F) | 140°C (284°F) | 135°C (275°F) |

| Target Application | Standard Automotive AC | High-Performance, EV, Critical Apps | General Automotive AC |

Note: This table represents typical characteristics. Actual product specifications should be verified with individual manufacturers.

Customized Solutions and Engineered Advantages

Leading manufacturers understand that off-the-shelf solutions may not always be optimal. We offer customized sae j2064 type c hose assemblies tailored to specific OEM design requirements, ensuring seamless integration and optimized performance. This can include:

- Specific Diameters and Lengths: Precision cutting and assembly to match vehicle architecture.

- Specialized Fittings & Connectors: Integration of custom or standard fittings (e.g., O-ring, quick connect) compatible with various AC system interfaces.

- Pre-formed Bends & Shapes: Hoses can be pre-formed to navigate complex engine bay layouts, reducing installation time and improving reliability by minimizing stress points.

- Enhanced Outer Cover Protection: Options for extra abrasion sleeves or heat shields for extreme environments.

- Optimized Barrier Technologies: Development of proprietary barrier layers to achieve even lower permeation rates for emerging refrigerants or critical applications.

By collaborating closely with engineering teams, we deliver solutions that not only meet sae j2064 standards but also contribute to overall system efficiency, reduced NVH (Noise, Vibration, and Harshness), and simplified assembly processes.

Figure 2: Example of a customized SAE J2064 Type C hose assembly with specialized fittings.

Real-World Application Case Studies

Case Study 1: Premium EV Manufacturer

Challenge: A leading electric vehicle manufacturer required AC hoses that could not only handle R-1234yf with ultra-low permeation but also withstand higher-than-average system pressures due to an integrated battery thermal management circuit. They also needed exceptional vibration dampening and long-term durability to match the vehicle's extended warranty period.

Solution: We collaborated with their engineering team to develop a custom sae j2064 type c hose. This solution featured a proprietary multi-layer barrier system with an optimized polyamide blend and an extra-thick, high-grade EPDM outer cover. The reinforcement braiding was also enhanced to provide superior burst strength (up to 250 bar) and fatigue resistance. Extensive impulse and vibration testing demonstrated performance exceeding SAE J2064 requirements by 25%.

Result: The tailored hose assembly achieved a permeation rate for R-1234yf of 2.2 kg/m²/year, significantly below the SAE J2064 Type C Class II limits. The enhanced durability contributed to zero field failures related to the hose assemblies within the first five years of production, supporting the OEM's reputation for reliability and minimizing warranty costs.

Case Study 2: Heavy-Duty Agricultural Equipment

Challenge: A manufacturer of large agricultural machinery needed robust AC hoses for cab climate control. Their equipment operates in extremely dusty, high-vibration, and broad temperature environments (-30°C to +50°C ambient). The existing hoses were prone to external abrasion and premature cracking.

Solution: We supplied sae j2064 type c hoses with an upgraded, highly abrasion-resistant EPDM outer cover and an additional textile sleeve in critical areas. The hose construction was specifically optimized for improved low-temperature flexibility and high-temperature integrity. Customized crimped fittings were designed to resist ingress of dust and moisture.

Result: The new hose assemblies drastically reduced field failures caused by external damage and environmental degradation. The product delivered a reliable service life of over 10,000 operational hours, leading to a 40% reduction in equipment downtime related to AC system maintenance and significantly improved operator comfort.

Ensuring Trust: FAQs, Lead Times, Warranty, and Support

Frequently Asked Questions (FAQs)

Q1: What is the primary difference between SAE J2064 Type C and other types?

A1: sae j2064 type c specifies a multi-layer hose assembly primarily for mobile AC applications, focusing on low permeation rates and durability. Other types within J2064 might differ in barrier materials, pressure ratings, or specific environmental resistances, but Type C is a widely recognized high-performance standard.

Q2: Are your hoses compatible with R-1234yf?

A2: Yes, all our sae j2064 type c hoses are rigorously tested and certified for compatibility with R-1234yf, ensuring low permeation and long-term performance with this next-generation refrigerant.

Q3: How do you ensure the quality of your products?

A3: Our manufacturing facilities adhere to IATF 16949 automotive quality management standards. We conduct extensive in-process and final product testing, including burst pressure, impulse, permeation, and vibration tests, far exceeding the minimum requirements of sae j2064.

Lead Time and Fulfillment

We maintain an efficient supply chain and optimized production schedules to meet diverse client needs. Standard product lead times typically range from 4-6 weeks for custom assemblies, following design approval. Expedited options are available for urgent requirements, subject to material availability and production capacity. Our global logistics network ensures timely and reliable delivery worldwide.

Warranty Commitments

We stand behind the quality and performance of our sae j2064 type c hoses. All products are backed by a comprehensive warranty against manufacturing defects and material failures, typically for 12 to 24 months, or based on specific contractual agreements with OEM partners. Details of our warranty policy are available upon request.

Customer Support and Technical Assistance

Our dedicated technical support team comprises experienced engineers ready to assist with product selection, design integration, and troubleshooting. We offer pre-sales consultation, post-sales support, and in-depth technical documentation. Our commitment is to foster long-term partnerships by providing unparalleled service and expertise.

Figure 3: Quality assurance testing in progress for SAE J2064 hoses.

Conclusion

The adherence to sae j2064 type c is more than just compliance; it's a testament to engineering excellence, reliability, and environmental responsibility in automotive air conditioning systems. As the industry advances towards more sustainable refrigerants and electrified powertrains, the demand for high-performance, durable, and low-permeation AC hoses will only intensify. Partnering with a manufacturer committed to these standards and continuous innovation ensures that your AC systems are not only efficient and long-lasting but also future-proof.

Authoritative References

- SAE International. "J2064: Refrigerant Hoses and Hose Assemblies for Mobile Air-Conditioning Systems." SAE Standards.

- ISO. "ISO/TS 16949: Quality management systems — Particular requirements for the application of ISO 9001:2008 for automotive production and relevant service part organizations." International Organization for Standardization.

- Society of Automotive Engineers. "Automotive Air Conditioning and Refrigerant Technology Standards."

- United States Environmental Protection Agency (EPA). "Significant New Alternatives Policy (SNAP) Program."

- Mobile Air Conditioning Society (MACS) Worldwide. "Service Procedures for R-1234yf."

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025