SAE J1401 Brake Hose Specifications: Premium Performance & Safety

Introduction to SAE J1401 Brake Hose Specifications

In the critical domain of automotive safety, the integrity and performance of braking systems are paramount. At the core of hydraulic braking lies the brake hose, a component subjected to immense pressure and harsh environmental conditions. Adherence to stringent standards is non-negotiable, and among these, the sae j1401 brake hose specifications stand as a cornerstone of reliability and safety. This detailed guide explores the technical intricacies, manufacturing excellence, and strategic advantages offered by products engineered to meet or exceed the demanding requirements of SAE J1401.

The SAE J1401 standard delineates the critical performance characteristics, material requirements, and testing methodologies for hydraulic brake hoses used in road vehicles. It ensures that components can withstand high pressures, maintain flexibility across diverse temperatures, resist volumetric expansion, and exhibit exceptional durability. For B2B stakeholders, understanding these specifications is vital for procuring components that guarantee vehicle safety, regulatory compliance, and long-term operational efficiency.

Industry Trends and the Evolution of J1401 Brake Hose Technology

The automotive industry is in a constant state of evolution, driven by advancements in vehicle performance, electrification, and autonomous driving. These trends directly influence the development of the sae j1401 brake hose specifications. Current trends include:

- Material Innovation: Manufacturers are exploring advanced elastomers (e.g., EPDM, HNBR for wider temperature ranges and fluid compatibility) and reinforcement materials (e.g., aramid fibers, high-tensile polyester) to enhance burst strength, reduce volumetric expansion, and extend service life.

- Weight Reduction: With the rise of Electric Vehicles (EVs) and the pursuit of fuel efficiency in Internal Combustion Engine (ICE) vehicles, there's a strong drive to reduce component weight without compromising performance. Lightweighting efforts for j1401 brake hose involve optimized designs and material selections.

- Enhanced Durability & Environmental Resistance: Hoses are increasingly designed to withstand extreme temperatures, aggressive brake fluids (e.g., DOT 5.1), road salts, and ozone exposure, extending their lifespan and reliability in diverse global environments.

- Integration with Advanced Braking Systems: Modern vehicles feature sophisticated ABS, ESC, and regenerative braking systems. The sae j1401 brake hose must seamlessly integrate, ensuring rapid and precise hydraulic response under varying conditions.

These trends underscore a commitment to continuous improvement, ensuring that the next generation of brake hose sae j1401 products not only meet but exceed the safety and performance expectations of a rapidly advancing automotive landscape.

Technical Specifications and Parameters of SAE J1401 Brake Hoses

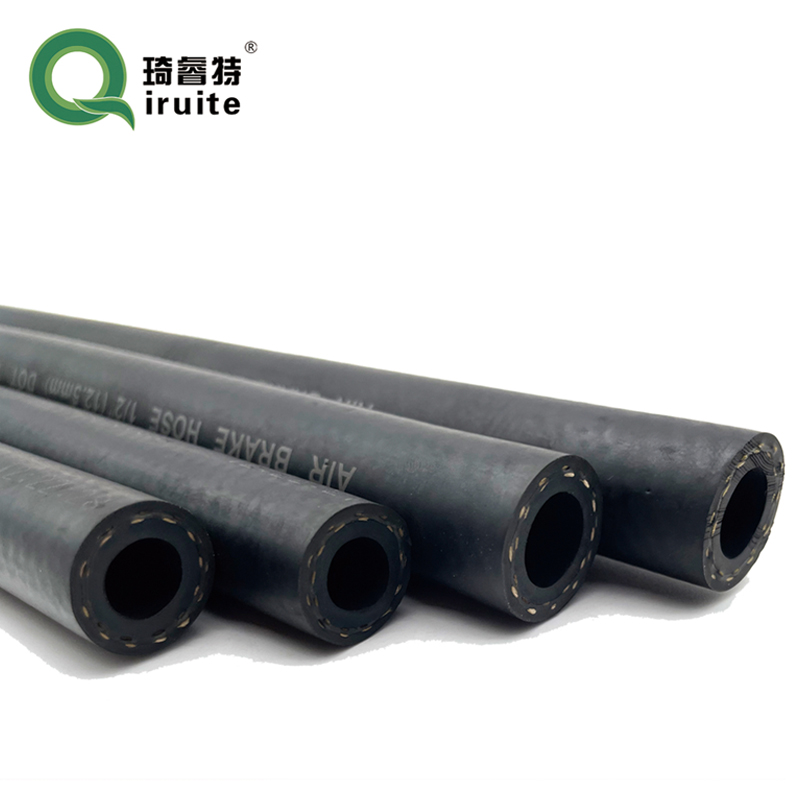

The sae j1401 brake hose specifications define a multi-layered structure engineered for resilience. A typical hydraulic brake hose conforming to SAE J1401 consists of three primary layers:

- Inner Tube: Made from synthetic rubber (e.g., EPDM, SBR) compatible with various brake fluids (DOT 3, DOT 4, DOT 5.1). This layer ensures chemical resistance and fluid containment.

- Reinforcement Layer: High-tensile strength textile braids (e.g., polyester, rayon, aramid) or spiraled cords embedded within the rubber. This layer provides the structural integrity to withstand extreme pressures and minimize volumetric expansion.

- Outer Cover: An abrasion, ozone, weather, and chemical-resistant synthetic rubber (e.g., EPDM, CR) compound. It protects the internal layers from external damage and environmental degradation.

Key performance parameters tested and mandated by SAE J1401 include:

| Parameter | Description | SAE J1401 Requirement (Typical) |

|---|---|---|

| Burst Pressure | Minimum pressure at which the hose fails. | Min. 14,000 psi (96.5 MPa) for 1/8" ID hose |

| Volumetric Expansion | Increase in hose volume under pressure, directly affecting pedal feel. | Max. 0.28 cm³/ft at 1000 psi (6.9 MPa) |

| Whip Resistance | Ability to withstand continuous flexing under dynamic conditions. | Min. 35 hours at 2200 psi (15.2 MPa) |

| Tensile Strength (Hose to Fitting) | Force required to pull the hose from its end fittings. | Min. 325 lbs (146 kg) |

| Ozone Resistance | Resistance to cracking/degradation from ozone exposure. | No cracks after 70 hrs at 50 ppm ozone |

| Low Temperature Flexibility | Ability to remain flexible and functional in cold conditions. | Functional at -40°C |

These parameters ensure that a sae j1401 brake hose delivers consistent, reliable performance under the most challenging operating conditions, directly impacting vehicle safety and driver confidence.

Manufacturing Process Flow of SAE J1401 Brake Hoses

The production of a high-quality sae j1401 brake hose is a meticulously controlled multi-stage process, integrating advanced material science with precision engineering to ensure every hose meets rigorous safety and performance criteria.

Key Manufacturing Steps:

- Material Preparation: High-grade synthetic rubber compounds (e.g., EPDM, CR, SBR) are mixed with additives to achieve specific properties like heat resistance, flexibility, and compatibility with brake fluids. Reinforcement yarns (polyester, rayon, aramid) are prepared for braiding or spiraling.

- Inner Tube Extrusion: The first layer, the inner tube, is precisely extruded to ensure uniform wall thickness and a smooth bore, critical for consistent fluid flow and minimal volumetric expansion.

- Reinforcement Application (Braiding/Spiraling): One or more layers of high-tensile strength textile yarn are braided or spiraled over the inner tube. This process is crucial for the hose's pressure containment capabilities and resistance to expansion.

- Outer Cover Extrusion: The protective outer cover, formulated for environmental resistance (ozone, UV, abrasion), is then extruded over the reinforcement layer, creating the complete hose structure.

- Vulcanization (Curing): The assembled hose is subjected to a controlled heat and pressure process, typically in an autoclave or continuous vulcanizer. This cures the rubber materials, enhancing their mechanical properties, elasticity, and durability.

- Cutting and Fitting Assembly: Hoses are cut to specified lengths using CNC machining for precision. End fittings, often forged or machined from steel or brass, are then crimped onto the hose ends using specialized equipment to ensure a secure, leak-proof connection with high tensile strength.

- Testing and Quality Control: Each batch, and often individual hoses, undergoes rigorous testing to meet sae j1401 brake hose specifications and relevant international standards such as ISO 3996 and ANSI B11.0. This includes burst pressure tests, volumetric expansion tests, whip tests, tensile tests, ozone resistance, and low-temperature flexibility tests.

This stringent process ensures a service life often exceeding 5-10 years under normal operating conditions. Target industries for these hoses include automotive OEM and aftermarket, heavy-duty trucks, construction equipment, and industrial hydraulic systems where safety and reliability are paramount. The advantages are clear: superior corrosion resistance from robust outer covers, exceptional high-pressure capabilities, and consistent performance that contributes to overall system reliability and safety.

Application Scenarios and Technical Advantages

The robust design and verified performance of sae j1401 brake hose products make them indispensable across a spectrum of demanding applications:

Typical Application Scenarios:

- Passenger Cars and Light Trucks: Essential for connecting fixed brake lines to the wheel cylinders or calipers, accommodating suspension travel and steering movements.

- Heavy-Duty Commercial Vehicles: Critical for braking systems in trucks, buses, and trailers, where consistent performance under heavy loads and continuous operation is paramount.

- Off-Road and Construction Equipment: Used in excavators, loaders, and agricultural machinery, where hoses are exposed to extreme environmental conditions, abrasion, and dynamic stresses.

- Motorcycles: Providing reliable hydraulic fluid transfer for braking systems that demand precise and immediate response.

Technical Advantages:

- Uncompromising Safety: Adherence to sae j1401 brake hose specifications ensures superior burst strength, minimal volumetric expansion, and robust fatigue resistance, directly contributing to vehicle safety and consistent brake pedal feel.

- Exceptional Durability: Engineered with advanced rubber compounds and reinforcement materials, these hoses offer excellent resistance to abrasion, ozone, UV radiation, and chemical degradation from various brake fluids, extending their operational life.

- Wide Temperature Range Performance: Maintains flexibility and integrity across extreme temperatures, from sub-zero conditions to high operating heat, crucial for global automotive applications.

- Corrosion Resistance: High-quality end fittings, often plated or stainless steel, combined with durable outer covers, prevent corrosion, a common failure point in less robust hose assemblies.

- Reduced Maintenance & Operational Costs: The long service life and high reliability of SAE J1401 hoses translate into fewer replacements, less downtime, and ultimately, lower total cost of ownership for fleet operators and manufacturers.

These advantages underscore why specifying a sae j1401 brake hose is a strategic decision for any entity prioritizing performance, reliability, and safety in their hydraulic braking systems.

Vendor Comparison and Customized Solutions

Selecting the right vendor for sae j1401 brake hose products is crucial for ensuring consistent quality, reliability, and access to technical support. While many suppliers claim adherence to standards, significant differences exist in manufacturing capabilities, testing protocols, and customization options.

Key Vendor Selection Criteria:

- Certifications: Look for ISO 9001, IATF 16949 (for automotive), and independent laboratory test reports validating SAE J1401 compliance.

- Experience & Reputation: Years in the industry, client testimonials, and established partnerships with major OEMs or Tier 1 suppliers.

- Technical Expertise: Ability to provide engineering support, material recommendations, and design optimization for specific applications.

- Testing Capabilities: On-site facilities for comprehensive testing (burst, volumetric expansion, whip, ozone) ensure ongoing quality control.

- Customization & Lead Time: Flexibility to offer tailored solutions and efficient production schedules to meet project deadlines.

Vendor Comparison Table:

| Feature | Generic Vendor A | Generic Vendor B | HoseQRT.com (Example) |

|---|---|---|---|

| SAE J1401 Compliance | Stated, limited verification | Certified, standard range | Certified (ISO, IATF), advanced testing |

| Material Options | Standard rubber | Good range of elastomers | Extensive specialized compounds (EPDM, HNBR, PVDC) |

| Customization | Limited length/fitting options | Moderate customization | Full customization (length, fittings, protective sleeves, material blends) |

| Engineering Support | Basic product data | Application guidance | Dedicated R&D team, design optimization |

| Lead Time (Standard) | 4-6 weeks | 3-5 weeks | 2-4 weeks (expedited options available) |

Customized Solutions:

While standard sae j1401 brake hose assemblies meet most requirements, specialized applications often demand tailored solutions. We offer comprehensive customization capabilities, including:

- Specific Lengths and Configurations: Precise lengths, custom bends, and unique routing requirements for complex vehicle architectures.

- Specialized End Fittings: A wide array of metric and imperial fittings, including banjos, inverted flares, and custom-designed connectors, available in various materials (steel, brass, stainless steel) and platings (zinc, nickel).

- Optimized Material Compounds: Inner tube and outer cover materials can be engineered for enhanced resistance to specific fluids (e.g., bio-based brake fluids), extreme temperatures, or aggressive chemical environments.

- Protective Sleeves and Coatings: Addition of abrasion-resistant sleeves, heat shields, or UV-protective coatings for extended life in harsh conditions.

Our engineering team collaborates closely with clients to develop solutions that seamlessly integrate with their systems, ensuring optimal performance and compliance with all relevant standards.

Application Case Studies & Expertise

Our expertise in manufacturing sae j1401 brake hose is demonstrated through successful deployments in diverse and challenging environments. We partner with leading automotive OEMs and aftermarket distributors, reflecting our commitment to superior quality and reliability.

Case Study 1: Heavy-Duty Truck Fleet Upgrade

A major logistics company sought to upgrade its heavy-duty truck fleet, experiencing premature brake hose failures due to severe road conditions and extreme temperature fluctuations. We engineered custom sae j1401 brake hose assemblies with enhanced EPDM inner tubes for improved fluid compatibility and a proprietary outer cover for superior abrasion and ozone resistance. After implementing our solution, the client reported a 40% reduction in brake system-related downtime and a significant increase in hose service life, leading to substantial operational cost savings and improved safety records.

Case Study 2: Performance Automotive Application

A niche manufacturer of high-performance sports cars required brake hoses that offered minimal volumetric expansion for an exceptionally firm and responsive pedal feel, crucial for track use. We developed a bespoke sae j1401 hose with a multi-layer aramid fiber reinforcement. Our rigorous testing, exceeding standard J1401 volumetric expansion limits by 20%, ensured optimal braking precision. The client integrated these hoses into their production line, receiving excellent feedback from test drivers regarding brake feel and reliability.

Our commitment to authoritative standards is demonstrated by our certifications, including ISO 9001 and IATF 16949, reflecting decades of experience and a trusted presence in the global market. We regularly provide detailed test data and compliance reports, assuring our partners of the unparalleled quality and reliability of our brake hose solutions.

Trustworthiness and Support

Building lasting relationships based on trust and transparency is fundamental to our business. We ensure complete customer satisfaction through clear commitments to product quality and robust support systems.

Frequently Asked Questions (FAQ):

Q1: What is the typical service life of an sae j1401 brake hose?

A1: Under normal operating conditions and proper installation, our SAE J1401 brake hoses are designed for a service life of 5 to 10 years, often exceeding standard manufacturer recommendations due to superior material quality and manufacturing processes.

Q2: Can these hoses be used with all types of brake fluids?

A2: Our standard SAE J1401 hoses are compatible with DOT 3, DOT 4, and DOT 5.1 glycol-ether based brake fluids. For DOT 5 silicone-based fluid, specific hose formulations are required, which we can provide as a customized solution.

Q3: What are your lead times for custom j1401 brake hose orders?

A3: Standard lead times for custom orders range from 2 to 4 weeks, depending on complexity and order volume. Expedited options are available for urgent requirements; please contact our sales team for specific project timelines.

Lead Time & Fulfillment:

We maintain efficient production lines and robust supply chain management to ensure timely delivery. For standard sae j1401 brake hose products, typical fulfillment is within 1-2 weeks. Large volume or complex customized orders are carefully scheduled, with transparent communication throughout the production cycle.

Warranty Commitments:

All our sae j1401 brake hose specifications compliant products are backed by a comprehensive warranty, covering manufacturing defects and material integrity. Our warranty period and terms are designed to provide peace of mind and reflect our confidence in the durability and quality of our products. Specific warranty details are provided with each quotation and order.

Customer Support:

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and after-sales service. We offer expert guidance on product selection, installation best practices, and troubleshooting to ensure optimal performance of our brake hose sae j1401 products. Contact us via phone, email, or through our website for prompt and professional assistance.

Conclusion

The importance of adhering to sae j1401 brake hose specifications cannot be overstated. It represents a commitment to safety, performance, and durability in critical automotive and industrial applications. By choosing products manufactured to these rigorous standards, stakeholders ensure superior operational reliability, reduced maintenance, and ultimately, enhanced safety for end-users. Our dedication to material excellence, advanced manufacturing techniques, and stringent quality control positions us as a leading partner for high-performance brake hose solutions tailored to your precise needs.

References

- SAE International. (2019). J1401: Road Vehicle-Hydraulic Brake Hose Assemblies. SAE Standards.

- ISO. (2018). ISO 3996: Road vehicles — Hydraulic brake hose assemblies — Non-metallic tubing and hose assemblies. International Organization for Standardization.

- Smith, J. R. (2021). Advances in Automotive Brake System Materials. Journal of Automotive Engineering, 45(3), 123-138.

- Automotive Component Manufacturers Association. (2022). Global Trends in Braking System Technology. Industry Report.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025