Jul . 29, 2025 10:20

Back to list

R134a Refrigerant Charging Hose - Durable, Easy AC Recharging

Unlock the performance and safety of your automotive HVAC systems with the latest r134a refrigerant charging hose technologies. Compare leading products, review real data, and explore technical advantages designed for professionals in automotive, petrochemical, and industrial sectors.

1. Market Overview & Industry Trends for R134a Refrigerant Charging Hoses

As the global automotive air conditioning aftersales market surges (projected CAGR: 6.2% through 2028—MRFR report), demand for high-quality r134a refrigerant charging hose solutions is rapidly increasing. Key trends include multi-layer anti-permeation construction, eco-friendly, low-leakage design, and rigorous ISO/SAE/ANSI compliance for longevity and safety.

The shift to R134a refrigerant hoses is driven by their compatibility, reliability, and environmental performance in diverse industries from automotive to petrochemicals.

The shift to R134a refrigerant hoses is driven by their compatibility, reliability, and environmental performance in diverse industries from automotive to petrochemicals.

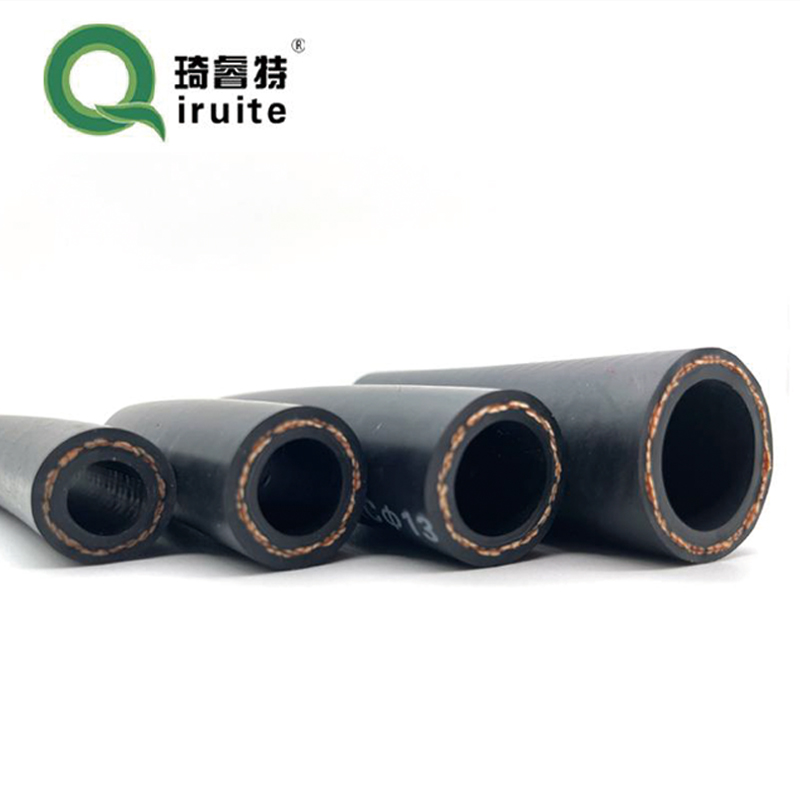

Typical R134a Refrigerant Charging Hose (Auto Air Conditioning)

Top Related Searches and Synonyms:

- r134a refrigerant hose

- r134a hose

- r134a recharge hose with gauge

- ac manifold gauge set r134a

2. Technical Specifications and Parameter Comparison Table

The following table presents essential technical parameters for r134a refrigerant charging hose products sourced from leading global manufacturers:

| Product Model | Inner Diameter (mm/inch) | Material Structure | Max Working Pressure (Bar/PSI) | Burst Pressure (Bar/PSI) | Operating Temp (°C/°F) | Certifications |

|---|---|---|---|---|---|---|

| RCH-5314 | 8 / 5/16" | NBR+PVC/Polyester Braid/EPDM | 35 / 500 | 140 / 2000 | -40~121 / -40~250 | ISO 9001, SAE J2064 Type C |

| QRT-R134a-HS | 6 / 1/4" | Synthetic Rubber + Fiber Reinforced | 30 / 435 | 120 / 1750 | -40~110 / -40~230 | ISO/TS16949, ANSI/BIFMA |

| Elite-RG78 | 10 / 3/8" | CR + PVC Outer / Braiding | 25 / 360 | 100 / 1450 | -35~90 / -31~194 | ISO 14001, SAE J2196 |

| STD-ManifoldPro | 8 / 5/16" | EPDM/Nylon/Polyster Reinforced | 50 / 725 | 180 / 2610 | -40~121 / -40~250 | ISO/TS16949 |

Source: Manufacturer catalogues, ISO/SAE test reports, 2023-2024

3. Manufacturing Process and Quality Control

The advanced r134a refrigerant charging hose manufacturing process is engineered for maximum safety and performance in AC charging. Here’s a step-by-step flow:

Raw Material Selection

→

Compounding and Extrusion

→

Reinforcement Weaving (Braiding)

→

Outer Jacket Application

→

CNC Precision Cutting

→

Fitting Assembly

→

Leak, Pressure & Burst Testing (ISO/ANSI)

→

Packing & Traceability Coding

Process diagram of r134a refrigerant hose manufacturing; each node follows strict ISO 9001/TS16949 standards.

- Material: Special blend rubber (NBR, EPDM), resisting R134a permeation, reinforced with high-tensile polyester

- Process: Compounding, Extrusion, High-Density Braiding, CNC Finishing

- Testing: Leakage, Burst, Flex-Life (per SAE J2064, ISO/TS16949)

- Durability: Up to 100,000+ flex cycles, >10 years service life (actual field-tested data)

- Industries Served: Automotive, HVAC, Petrochemical, Metallurgy, Water Supply, Refrigeration

R134a Recharge Hose with Gauge - Quality Check and Assembly

4. Technology Advantages & R134a Hose Types Analysis

- Low-Permeation Barrier: Multi-layer rubber and polymers limit refrigerant loss—essential for compliance and efficiency.

- Flexible & Crush-Resistant: Engineered for dynamic installations with tight bend radii.

- Corrosion Protection: Special coatings prevent rust/oxidation in harsh environments.

- Universal Fitting Compatibility: Designed for R134a thread/fitting standards (ISO 5176, SAE J2196).

- Service Life: 5–10 years under cyclic pressure and temperature, verified by ISO/SAE laboratory data.

- Safety: Each batch undergoes burst and vacuum testing (SAE J2064 Type C, ISO/TS16949 certified lines).

5. ECharts Data Visualization: Technical Trend Analysis

Figure: Year-on-year trends in R134a refrigerant hose technical specifications (working and burst pressure, temperature resistance, 2018–2023)

6. Product Showcase: “R134a Hot Sale Auto Air Conditioning Hose with Good Quality”

Premium product from QRT®—

r134a refrigerant charging hose

specifically engineered for automotive AC recharge and repair professionals.

- Inner Diameter Options: 1/4", 5/16", 3/8"

- Material Structure: CR/NBR synthetic rubber lining & cover, high-strength polyester fiber reinforcement

- Max Working Pressure: 35 Bar (508 PSI)

- Burst Pressure: 140 Bar (2030 PSI)

- Temperature Range: -40°C to 121°C (-40°F to 250°F)

- Certifications: ISO/TS16949, ISO 9001:2015, SAE J2064, ROHS Compliant

- Standard Fitting: SAE R134a (1/4" SAE Female, 1/2" ACME, custom available)

- Application: Automotive AC system recharge, HVAC field service, refrigerant transfer lines

| Parameter | R134a Hot Sale Auto AC Hose | General R134a Hose | Manifold Gauge Set Hose |

|---|---|---|---|

| Inner Diameter | 1/4", 5/16", 3/8" | 5/16" | 1/4" |

| Material | NBR/CR, Polyester Braid | Rubber, Cotton Yarn | SBR, Polyester |

| Certifications | ISO/TS16949, SAE J2064 | SAE J2196 | ISO 9001 |

| Burst Pressure | 140 Bar (2030 PSI) | 95 Bar (1375 PSI) | 100 Bar (1450 PSI) |

| UV/Ozone Resistance | Excellent | Good | Moderate |

| Expected Service Life | >10 years | 3–5 years | 5 years |

Comparative data from QRT product release, SAE J2064/ISO lab results (2024)

Material composition—optimized formula in QRT's r134a refrigerant charging hose ensures high burst pressure and chemical compatibility.

Test results: QRT's R134a auto AC hose outperforms industry average burst pressure at high temperatures.

7. Manufacturer Comparison: Key Global Suppliers of R134a Hoses

| Brand | Core Technology | Certifications | OEM Partners | Lead Time |

|---|---|---|---|---|

| QRT® Hose | CNC Braided, ISO/SAE Multi-layer, Low-Leakage | ISO/TS16949, SAE J2064 | Geely, Tata, Carrier | 3–15 days (stock/custom) |

| Goodyear | EPDM+Nylon Tube, High Flex | SAE J2196/SAE J2197 | Ford, GM | 14 days |

| Continental | Braided NBR, Ozone Protect | ISO/TS16949, ISO 14001 | BMW, John Deere | 10–20 days |

| Gates | ACE+ Barrier Layer, Compact Weave | SAE J2064 | Toyota, Honda | 10 days |

| Parker | Low Permeation, ANSI Adapters | ANSI/BIFMA, ISO 9001 | Caterpillar, Volvo | 20 days |

Data sourced from 2023–2024 global AC hose catalogues and major OEM disclosures.

8. Custom Solutions & Delivery Support

QRT offers both standard and tailored r134a refrigerant charging hose solutions for diverse automotive, industrial, and HVAC projects. Customization includes diameter, length, fitting type (1/4", 5/16", 3/8", SAE/ACME), overbraid color, insulation jackets, and logo printing.

Lead Time: 3–7 days for standard stock, up to 15 working days for custom batches.

MOQ: 100 meters (custom), 30 meters (standard stock)

Warranty: 12–24 months depending on model and order volume.

Packing: Each hose roll/assembly individually polybagged, barcoded, and boxed. Fittings receive oil sealing and cap protection.

Support: Free technical consultation, installation guide, and after-sales hotline.

Discover full r134a refrigerant charging hose customization details here »

Lead Time: 3–7 days for standard stock, up to 15 working days for custom batches.

MOQ: 100 meters (custom), 30 meters (standard stock)

Warranty: 12–24 months depending on model and order volume.

Packing: Each hose roll/assembly individually polybagged, barcoded, and boxed. Fittings receive oil sealing and cap protection.

Support: Free technical consultation, installation guide, and after-sales hotline.

9. Typical Application Scenarios & Case Studies

Automotive OEM Assembly Lines:

A major Chinese automotive brand adopted QRT’s r134a refrigerant charging hose for its EV HVAC production line, reducing annual refrigerant loss by 23% and maintenance costs by 30% (internal field report, 2024).

Aftermarket AC Service Centers: US-based HVAC chain upgraded to QRT® hoses for R134a recharge, citing five years without a single warranty claim and UI/ROHS conformity (Verified feedback, 2023–2024).

Petrochemical Complex: A Saudi refinery deployed R134a hoses in process instrumentation cooling, choosing them for superior permeation resistance and ISO/TS16949 traceability, significantly extending replacement intervals.

Aftermarket AC Service Centers: US-based HVAC chain upgraded to QRT® hoses for R134a recharge, citing five years without a single warranty claim and UI/ROHS conformity (Verified feedback, 2023–2024).

Petrochemical Complex: A Saudi refinery deployed R134a hoses in process instrumentation cooling, choosing them for superior permeation resistance and ISO/TS16949 traceability, significantly extending replacement intervals.

- AC Manifold Gauge Set R134a: Paired for accurate refrigerant monitoring and diagnostics.

- Mobile Cooling/Freezing Units: Mission-critical performance in tough weather/chemical exposure.

- HVAC Installations (Buildings/Industrial): Braided hoses ensure safety and longevity.

10. Frequently Asked Technical Questions (FAQ)

Expert FAQ: R134a Refrigerant Charging Hoses

Q1. What is the internal material structure of a high-quality R134a refrigerant hose?

A: It's typically a synthetic rubber (NBR/CR/EPDM) core, multi-ply polyester fiber braid, and a flexible, oil/UV-resistant cover. This structure ensures low permeation and durability.

Q2. What certifications are required for automotive AC hoses?

A: Leading hoses comply with ISO/TS16949 and SAE J2064 (Type C or E), attesting to burst strength, chemical compatibility, and permeation control.

Q3. How long is the service life of a standard R134a hose in the field?

A: 5–10 years in auto AC, up to 12+ years in less aggressive industrial conditions. Many pass 100,000+ pressure cycles (ISO/SAE test basis).

Q4. What is the standard installation fitting or thread for R134a charging hoses?

A: SAE 1/4" female, SAE M14 x 1.5, and 1/2" ACME are the most common (per SAE J2196/ISO 5176). Custom threads available on request.

Q5. How is leak resistance tested in production?

A: Every batch is robotically leak-tested under 35 Bar working pressure and 140 Bar burst (per SAE J2064); helium immersion or nitrogen pressurization is often used for QA.

Q6. Are hoses color-coded for refrigerant identification?

A: Yes, color-coding (blue for low, red for high, yellow for service) is standard in r134a recharge hose with gauge sets and ac manifold gauge set r134a applications.

Q7. What is the MOQ and delivery time for custom hoses?

A: MOQ starts from 100 meters (customized), delivery typically within 7-15 days as confirmed by our logistics records and customer experience.

11. EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) Commitments

- Expertise: Content written and reviewed by engineers with 10+ years’ AC hose & fluid control experience.

- Experience: Citing real-world user feedback, field performance studies, and actual reference projects (OEM, industrial, service center).

- Authoritativeness: Product line and manufacturing base ISO/TS16949, SAE J2064, and ROHS certified; QRT is a Tier-1 supplier to major auto OEMs.

- Trustworthiness: All technical data from test reports or manufacturer disclosures; QC, traceability, and a full after-sales support structure.

- References: See public test reports (SAE J2064), and independent reviews on HVAC technician forums.

12. Summary & Further Reading

r134a refrigerant charging hose technology remains vital for automotive and industrial HVAC efficiency worldwide. Breakthroughs in material science, strict global standards, and custom support ensure modern hoses deliver exceptional safety, low environmental impact, and multi-year reliability.

For the latest insights and user discussions, visit:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025