Feb . 04, 2025 01:34

Back to list

40mm female coupling

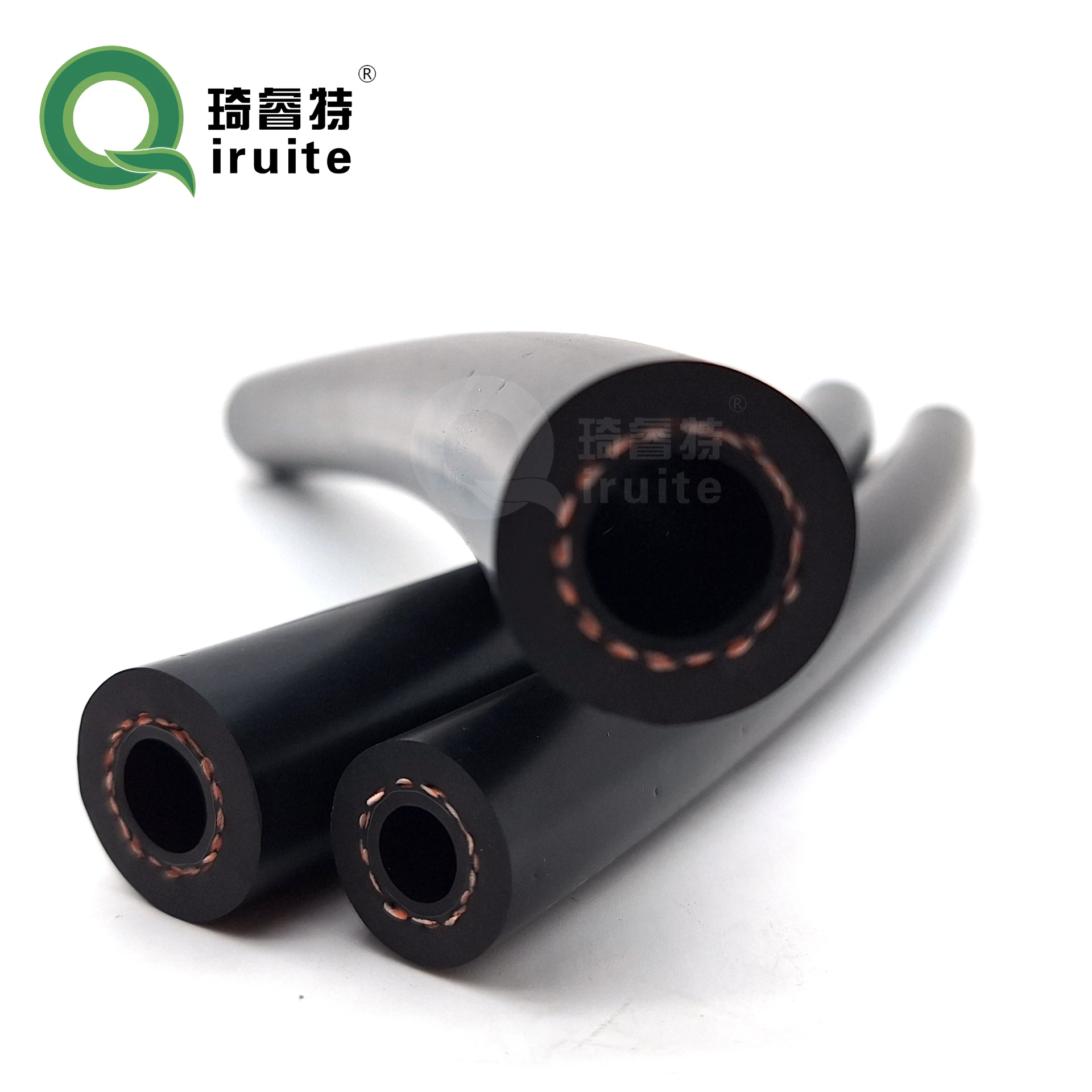

Choosing the right coupling for a specific application can significantly influence the efficiency and longevity of your equipment. The 40mm female coupling, in particular, serves as a vital component across various industries such as oil and gas, chemical processing, and water treatment. Understanding its functionalities, applications, and benefits can assist professionals in making informed decisions. This article delves deep into the intricacies of the 40mm female coupling, highlighting its significance and practical applications.

Authoritativeness in the realm of 40mm female couplings comes from adherence to international standards such as ISO and ANSI. These standards outline the specifications including materials, dimensions, and testing procedures required to ensure couplings handle specified pressures and operational conditions. Utilizing couplings that meet these standards not only enhances performance but also contributes to industry compliance, thus avoiding potential regulatory fines. In terms of trustworthiness, customer testimonials and case studies serve as invaluable resources. Reports of successful implementations where 40mm female couplings have contributed to seamless project execution bolster confidence in potential buyers. Companies that prioritize transparency in testing results and offer substantive warranties are more likely to be trusted by customers needing reliable components that maintain system integrity. Furthermore, innovation within coupling technology continues to evolve. Advanced sealing techniques and precision machining enhance coupling efficiency and durability. Implementing smart technology, such as sensors to monitor connectivity and leakage in real-time, represents the future of fluid management systems, allowing for preemptive maintenance, and further minimizing downtime. In conclusion, the 40mm female coupling is more than just a connector; it is a linchpin in many industrial systems. Through understanding its functional parameters, material benefits, and installation nuances, industries can ensure they select a coupling that upholds operational efficiency and safety standards. Staying informed about evolving technologies and industry standards will continuously drive improvement and trustworthiness in fluid management solutions.

Authoritativeness in the realm of 40mm female couplings comes from adherence to international standards such as ISO and ANSI. These standards outline the specifications including materials, dimensions, and testing procedures required to ensure couplings handle specified pressures and operational conditions. Utilizing couplings that meet these standards not only enhances performance but also contributes to industry compliance, thus avoiding potential regulatory fines. In terms of trustworthiness, customer testimonials and case studies serve as invaluable resources. Reports of successful implementations where 40mm female couplings have contributed to seamless project execution bolster confidence in potential buyers. Companies that prioritize transparency in testing results and offer substantive warranties are more likely to be trusted by customers needing reliable components that maintain system integrity. Furthermore, innovation within coupling technology continues to evolve. Advanced sealing techniques and precision machining enhance coupling efficiency and durability. Implementing smart technology, such as sensors to monitor connectivity and leakage in real-time, represents the future of fluid management systems, allowing for preemptive maintenance, and further minimizing downtime. In conclusion, the 40mm female coupling is more than just a connector; it is a linchpin in many industrial systems. Through understanding its functional parameters, material benefits, and installation nuances, industries can ensure they select a coupling that upholds operational efficiency and safety standards. Staying informed about evolving technologies and industry standards will continuously drive improvement and trustworthiness in fluid management solutions.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025