Jan . 26, 2025 07:28

Back to list

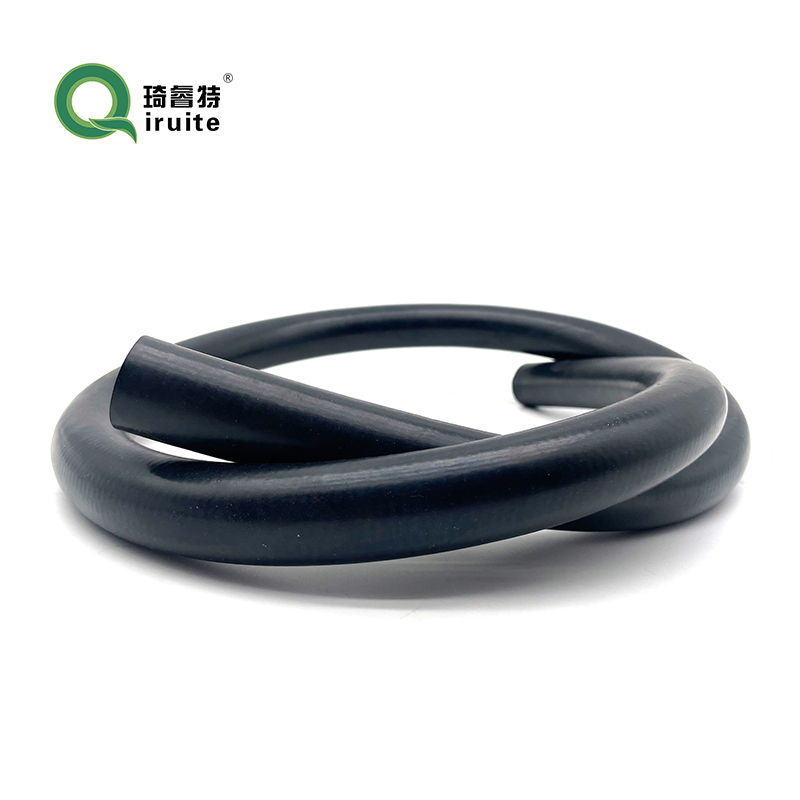

E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE

When selecting the right pipe coupling for your project, the importance of understanding the specifics of the product cannot be overstated. Today, the 3 8 pipe coupling stands out as a unique product in a vast array of coupling solutions. Catering specifically to infrastructure that requires strong, reliable connectivity in small-diameter pipelines, the 3 8 coupling holds a niche place in the plumbing and construction industries. Drawing from extensive expertise and practical applications, let's explore why this particular product is often preferred by seasoned professionals.

Furthermore, their design effectively minimizes potential leakage points, a common concern in plumbing systems. By ensuring a tight seal, whether through compression or threaded designs, the 3 8 coupling reduces maintenance needs and increases the overall reliability of the piping network. This effectiveness in preventing leaks not only conserves resources but also protects surrounding furnishings and infrastructures from water damage, promoting long-term structural integrity. Expert users of the 3 8 pipe coupling often extol its adaptability. These couplings are crafted to fit within a framework that supports easy modifications and expansions, an essential feature for evolving infrastructure requirements. Whether incorporating new technology or simply expanding upon existing plumbing systems, these couplings provide the flexibility necessary for modern construction demands, ensuring seamless transitions and fewer disruptions. Trust in the 3 8 pipe coupling is further cemented by endorsements from established authorities in the plumbing industry. Many regulatory bodies and certification organizations have provided seals of approval for this coupling's durability and safety standards, making it a reliable choice for any professional seeking to ensure compliance with stringent building codes and plumbing standards. In conclusion, the 3 8 pipe coupling is much more than a simple fitting. It represents a careful blend of practicality, durability, and flexibility that professionals depend upon. By prioritizing these factors, installers and engineers can ensure successful projects with long-term, reliable outcomes. As plumbing and infrastructure continue to evolve, this component remains a trusted mainstay, showcasing the perfect balance of form and function in the world of pipe fittings.

Furthermore, their design effectively minimizes potential leakage points, a common concern in plumbing systems. By ensuring a tight seal, whether through compression or threaded designs, the 3 8 coupling reduces maintenance needs and increases the overall reliability of the piping network. This effectiveness in preventing leaks not only conserves resources but also protects surrounding furnishings and infrastructures from water damage, promoting long-term structural integrity. Expert users of the 3 8 pipe coupling often extol its adaptability. These couplings are crafted to fit within a framework that supports easy modifications and expansions, an essential feature for evolving infrastructure requirements. Whether incorporating new technology or simply expanding upon existing plumbing systems, these couplings provide the flexibility necessary for modern construction demands, ensuring seamless transitions and fewer disruptions. Trust in the 3 8 pipe coupling is further cemented by endorsements from established authorities in the plumbing industry. Many regulatory bodies and certification organizations have provided seals of approval for this coupling's durability and safety standards, making it a reliable choice for any professional seeking to ensure compliance with stringent building codes and plumbing standards. In conclusion, the 3 8 pipe coupling is much more than a simple fitting. It represents a careful blend of practicality, durability, and flexibility that professionals depend upon. By prioritizing these factors, installers and engineers can ensure successful projects with long-term, reliable outcomes. As plumbing and infrastructure continue to evolve, this component remains a trusted mainstay, showcasing the perfect balance of form and function in the world of pipe fittings.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025