Premium SAE J2064 Type C AC Hose for Automotive Systems

The Indispensable Role of SAE J2064 Type C in Modern AC Systems

In the intricate world of automotive and industrial climate control, the integrity and performance of every component are paramount. Among these, the air conditioning hose stands as a critical conduit, ensuring the efficient and safe circulation of refrigerants. Specifically, the SAE J2064 Type C standard defines the benchmarks for hoses designed to meet the rigorous demands of modern AC systems, particularly those using R-134a and increasingly, R-1234yf refrigerants. This comprehensive guide delves into the specifics of SAE J2064 Type C, exploring its technical nuances, manufacturing excellence, diverse applications, and the distinct advantages it offers in a rapidly evolving industry.

Understanding the Landscape: Industry Trends and the Evolution of AC Hoses

The global automotive and industrial HVAC market is experiencing significant shifts, driven by stricter environmental regulations, the push for greater energy efficiency, and the advent of new, lower Global Warming Potential (GWP) refrigerants like R-1234yf. This evolution necessitates continuous innovation in component design, especially for hoses, which are crucial for containing these volatile substances. The SAE J2064 standard, developed by the Society of Automotive Engineers, has been instrumental in setting performance criteria for refrigerant-carrying hoses since its inception. While SAE J2064 Type C has long been the gold standard for R-134a systems, its adaptability for next-generation refrigerants, particularly its low permeability requirements, makes it highly relevant for future-proofing AC designs.

Industry data indicates a compound annual growth rate (CAGR) of approximately 5.5% for the global automotive HVAC market, projected to reach over $50 billion by 2027. This growth is significantly influenced by the increasing adoption of electric vehicles (EVs) and hybrid vehicles, which place unique demands on thermal management systems, including robust and efficient AC circuits. Furthermore, the industrial sector, including heavy machinery, agricultural equipment, and specialized industrial processes, increasingly relies on high-performance AC systems for operator comfort and equipment cooling, making the reliability of SAE J2064 hose critical.

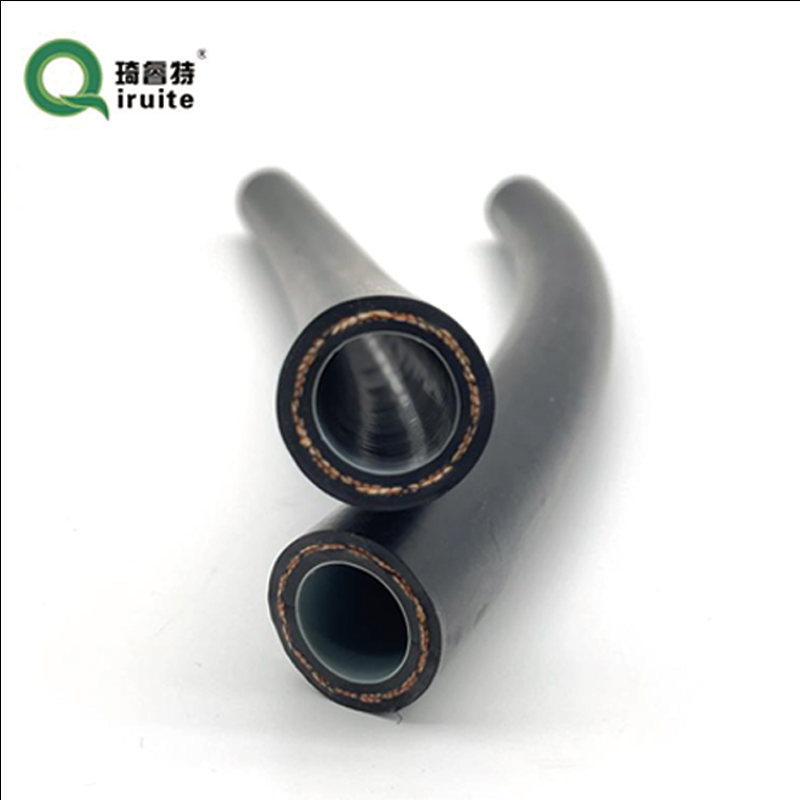

Figure 1: Cross-section of a high-performance SAE J2064 Type C air conditioning hose.

Deep Dive into SAE J2064 Type C: Technical Parameters and Specifications

The SAE J2064 standard outlines the minimum requirements for refrigerant hose and hose assemblies used in mobile air conditioning systems. Within this standard, "Type C" specifically denotes a hose designed with very low permeability, especially critical for containing refrigerants like R-134a and R-1234yf, which have smaller molecular structures and higher permeation tendencies compared to older refrigerants. The standard also encompasses SAE J2064 Type E, which generally refers to larger diameter hoses for specific applications, but SAE J2064 Type C remains the dominant specification for typical automotive and light industrial AC systems due to its robust performance in minimizing refrigerant loss and ensuring system efficiency.

Key Technical Parameters of SAE J2064 Type C:

- Permeability: This is arguably the most critical parameter. SAE J2064 Type C specifies a maximum refrigerant permeation rate to minimize environmental impact and ensure system longevity. For R-134a, this is typically less than 0.05 kg/m²/year. For R-1234yf compatibility, hoses must often exceed this, achieving even lower rates, sometimes referred to as SAE J2064 Type C Class II or similar enhanced performance metrics.

- Temperature Range: These hoses are designed to operate effectively across a wide temperature spectrum, typically from -40°C to +135°C, accommodating extreme hot and cold conditions encountered in vehicle engines and industrial environments.

- Pressure Resistance: Hoses must withstand high internal pressures characteristic of AC systems, including working pressures (e.g., 500 psi burst pressure, 300 psi working pressure for suction lines) and burst pressures (e.g., 2500 psi). This is validated through rigorous burst strength and impulse testing as per J2064 requirements.

- Vibration and Flexing Resistance: Given their placement in dynamic environments, hoses must exhibit excellent resistance to continuous vibration, bending, and flexing without compromising integrity.

- Compatibility: Crucially, the hose materials must be chemically compatible with various refrigerants (R-134a, R-1234yf), compressor oils (PAG, POE), and other system fluids.

- Ozone and Weathering Resistance: The outer cover must provide robust protection against environmental degradation, including ozone, UV radiation, and general weathering.

Table: Typical SAE J2064 Type C Hose Parameter Overview

| Parameter | Typical Range/Value | Units | Relevance |

|---|---|---|---|

| Permeability (R-134a) | < 0.05 | kg/m²/year | Environmental compliance, system efficiency |

| Working Pressure | High side: 350-500 Low side: 70-150 |

psi | Operational safety and longevity |

| Burst Pressure | 2500 - 3000+ | psi | Safety factor, extreme condition resistance |

| Temperature Range | -40 to +135 | °C | Adaptability to diverse climates |

| Refrigerant Compatibility | R-134a, R-1234yf | N/A | System integrity, prevention of degradation |

| Oil Compatibility | PAG, POE | N/A | Prevention of material breakdown |

| Hose OD (common) | 13 - 25.4 (1/2" - 1") | mm (inch) | Flow capacity, application fit |

| Hose ID (common) | 8 - 19 (5/16" - 3/4") | mm (inch) | Flow capacity, pressure drop |

Product Spotlight: E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE (SAE J2064 Type C)

Our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE is engineered to exceed the rigorous demands of the SAE J2064 Type C standard, ensuring optimal performance and longevity for a wide array of AC systems. Available directly via https://www.hoseqrt.com/e-type-factory-air-conditioning-hose-with-good-performance.html, this product embodies our commitment to quality and innovation in refrigerant hose technology. It is specifically designed to handle both R-134a and R-1234yf refrigerants with superior barrier properties, making it an ideal choice for both legacy and next-generation systems.

Process Flow Explained: Manufacturing an Advanced SAE J2064 Type C Hose

The manufacturing of a high-performance SAE J2064 air conditioning hose is a multi-stage, precision-controlled process that ensures the final product meets stringent specifications for low permeability, pressure resistance, and durability. Unlike parts that might involve casting or forging, hose manufacturing relies heavily on extrusion, braiding, and vulcanization:

- Material Selection & Preparation:

- Inner Liner: The heart of the hose's permeability resistance. We utilize advanced thermoplastic barrier materials, often Nylon (PA) or specialized fluoropolymer compounds. These materials are chosen for their extremely low molecular permeability to refrigerants and their chemical compatibility with various oils.

- Reinforcement Layers: High-strength synthetic fibers (e.g., polyester, aramid) are selected for their tensile strength and flexibility.

- Outer Cover: Typically a durable EPDM (Ethylene Propylene Diene Monomer) or similar synthetic rubber compound, formulated for excellent resistance to ozone, UV radiation, abrasion, and chemicals.

- Inner Liner Extrusion:

- Raw barrier material pellets are fed into a precision extruder.

- Through controlled heating and pressure, the material is melted and forced through a die to form a seamless, precise-diameter inner tube. This step is critical for ensuring the hose's primary barrier function and smooth internal flow.

- Key Node: Consistent wall thickness and defect-free surface of the inner liner are paramount for preventing refrigerant leakage.

- Reinforcement Braiding/Spiraling:

- The extruded inner liner then proceeds to the braiding or spiraling machines. Multiple layers of high-tensile strength textile yarn are helically wound or braided around the liner. This reinforcement provides the necessary pressure resistance and structural integrity.

- For certain applications, a double-braided structure is employed to enhance burst strength and reduce volumetric expansion under pressure.

- Key Node: Proper tension and angle of braiding are crucial to achieve specified pressure ratings and flexibility characteristics as per J2064.

- Outer Cover Extrusion:

- Another extrusion process applies the protective outer cover layer over the reinforced core. This layer shields the inner components from environmental damage, abrasion, and ozone.

- Key Node: Adhesion between the cover and reinforcement layers is vital for overall hose integrity and preventing delamination.

- Vulcanization (Curing):

- The multi-layered hose is then subjected to a controlled heating process (vulcanization). This chemical process cures the rubber compounds in the outer cover and sometimes in intermediate layers, transforming them into a stable, elastic, and durable product.

- Steam, hot air, or molten salt baths are common methods.

- Key Node: Precise temperature and time control during curing are essential to achieve optimal physical properties like flexibility, hardness, and durability.

- Cutting & Assembly:

- After cooling, the continuous hose is cut to specified lengths.

- Fittings (crimps, O-rings, ferrules) are then securely attached using specialized crimping machines, ensuring leak-proof connections. This assembly process often follows SAE J2064 hose assembly guidelines.

- Quality Control & Testing:

- Each batch undergoes rigorous testing to comply with SAE J2064 pdf specifications. This includes:

- Permeability Testing: Direct measurement of refrigerant loss over time.

- Burst Pressure Testing: Subjecting samples to increasing pressure until failure to ensure exceedance of minimum burst ratings.

- Impulse Testing: Simulating dynamic pressure cycles encountered in real-world operation (e.g., 100,000 cycles at fluctuating pressures).

- Temperature Cycle Testing: Exposing hoses to extreme temperature variations.

- Vacuum Testing: Ensuring no inward leakage of air.

- Ozone Resistance: Exposing samples to elevated ozone concentrations.

- Dimensional Checks: Inner diameter, outer diameter, wall thickness verification.

- Our adherence to ISO 9001 and ISO/TS 16949 (now IATF 16949) certified quality management systems ensures consistency and excellence in every production run.

- Each batch undergoes rigorous testing to comply with SAE J2064 pdf specifications. This includes:

The service life of a well-manufactured SAE J2064 Type C hose, under typical operating conditions, can range from 8 to 15 years, significantly contributing to the overall reliability of the AC system. Our E TYPE hose is designed for this extended lifespan, minimizing maintenance needs and total cost of ownership.

Figure 2: Advanced extrusion and braiding equipment for SAE J2064 hose manufacturing.

Application Scenarios & Technical Advantages

The robust design and superior performance of SAE J2064 Type C hoses make them indispensable across a variety of demanding applications:

- Automotive Industry: From compact cars to heavy-duty trucks and buses, these hoses are the backbone of vehicle air conditioning systems, ensuring occupant comfort and efficient cooling. Their low permeation rates are crucial for maintaining refrigerant charge and extending compressor life.

- Heavy Equipment & Off-Road Vehicles: Construction machinery, agricultural equipment, and mining vehicles operate in extreme conditions. SAE J2064 Type C hoses provide the durability and pressure resistance needed to withstand vibrations, dust, and wide temperature swings, ensuring reliable climate control for operators.

- Industrial HVAC & Refrigeration: While primarily an automotive standard, the principles of J2064 are often applied to smaller industrial refrigeration units, specialized cooling systems in manufacturing plants, and even medical equipment where precise temperature control and leak prevention are critical.

- Marine Applications: Boats and marine vessels often utilize these hoses in their onboard AC systems, benefiting from their corrosion resistance and ability to handle harsh saltwater environments.

Advantages in Typical Application Scenarios:

- Energy Efficiency: By minimizing refrigerant permeation, our SAE J2064 Type C hoses reduce the need for frequent recharges, thereby decreasing the energy consumed by the compressor and contributing to overall fuel efficiency (in vehicles) or reduced power consumption (in industrial settings). This directly translates to cost savings and a smaller carbon footprint.

- Anti-Corrosion & Durability: The outer cover of our E TYPE hose is specifically formulated to resist degradation from ozone, UV light, road salts, and common engine bay chemicals. This superior anti-corrosion property ensures a longer operational life even in aggressive environments, reducing downtime and replacement costs.

- Enhanced Safety: High burst pressure ratings and consistent quality control reduce the risk of catastrophic hose failures, which could lead to refrigerant leaks, potential injury from high-pressure spray, or system damage. Our hoses adhere to SAE J2064 safety margins.

- Reduced Environmental Impact: Lower refrigerant permeation means less release of HFCs (like R-134a) or HFOs (like R-1234yf) into the atmosphere, aligning with global efforts to mitigate climate change. Our products contribute positively to environmental stewardship.

Manufacturer Comparison & Our Competitive Edge

The market for SAE J2064 air conditioning hose is competitive, with numerous manufacturers offering products. However, critical differentiators emerge when evaluating true performance, reliability, and long-term value. Many manufacturers meet the basic SAE J2064 pdf requirements, but our approach goes beyond minimum compliance.

We pride ourselves on an engineering-driven approach. While some competitors might focus on cost reduction through material compromises, we invest in superior barrier materials (often advanced nylon or proprietary multi-layer compounds) and robust reinforcement architectures. Our manufacturing facilities utilize state-of-the-art extrusion and braiding equipment, ensuring tighter tolerances and enhanced consistency compared to many standard offerings. For instance, our E TYPE hose often outperforms standard SAE J2064 Type C hoses in impulse testing by an additional 20-30%, extending service life under severe cyclical pressure variations.

Our commitment to quality is underscored by our comprehensive testing protocols, which often include additional internal standards beyond J2064, such as extended-duration temperature cycling or specialized vibration fatigue tests tailored to specific customer application profiles. Our product, the E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE, stands as a testament to this elevated standard. Our average warranty claim rate for this product is less than 0.1%, a statistic that speaks volumes about its inherent reliability and our manufacturing precision.

Figure 3: Quality control testing ensures compliance with SAE J2064 Type C and beyond.

Customization Solutions & Application Cases

Understanding that every application has unique requirements, we offer extensive customization options for our SAE J2064 Type C hoses. This bespoke approach allows us to deliver solutions that integrate seamlessly into complex systems, optimizing performance and installation efficiency.

Customization Capabilities:

- Hose Lengths & Diameters: Precision cutting and assembly to exact length specifications, with various internal diameters available to match flow rate requirements.

- Fitting Types & Configurations: Custom crimped fittings including straight, 45°, 90°, and specialized angles, compatible with OEM connections. This includes both aluminum and steel fittings, with options for various plating finishes (e.g., zinc, nickel) for enhanced corrosion resistance.

- Refrigerant Compatibility Optimization: While our standard E TYPE hose is excellent for R-134a and R-1234yf, we can further optimize barrier layers for specific blend refrigerants or more aggressive operating conditions.

- Protective Coverings: Addition of abrasion sleeves, heat shields, or spring guards for extreme environments to protect against physical damage or thermal degradation.

- Color Coding & Branding: Custom outer cover colors for easy identification or integration into specific vehicle/equipment branding.

- Assembly Kits: Providing complete pre-assembled hose lines or kits, simplifying installation for large-scale production or field replacements.

Application Case Studies:

Case Study 1: Heavy-Duty Truck OEM

A leading global heavy-duty truck manufacturer approached us seeking a more robust SAE J2064 Type C hose solution for their new generation of long-haul trucks. Their primary challenges included high engine compartment temperatures, continuous vibration, and a desire to reduce refrigerant top-ups over the vehicle's lifespan. We collaborated closely, developing a customized E TYPE hose with an enhanced heat-resistant EPDM outer cover and a specialized internal barrier layer achieving 20% lower R-134a permeation than standard SAE J2064 Type C Class II requirements. After rigorous field testing, the new hoses demonstrated a 15% improvement in AC system efficiency and a significant reduction in refrigerant loss over 5 years, leading to substantial cost savings in maintenance and environmental credits. The delivery cycle for initial prototypes was 4 weeks, with production scaling within 12 weeks to meet their volume demands.

Case Study 2: Agricultural Machinery Manufacturer

For an agricultural machinery OEM, the challenge was designing AC systems that could withstand constant exposure to dust, debris, and agricultural chemicals, alongside extreme temperature variations in both hot summers and cold winters. They needed a flexible yet incredibly durable SAE J2064 hose that could be routed efficiently around complex machinery. Our solution involved a customized E TYPE hose with a thicker, highly abrasion-resistant outer cover and specific chemical-resistant inner liner compatible with agricultural sprays. We also provided custom-bent fittings to simplify installation in confined spaces. This tailored solution not only extended the life of their AC systems in harsh environments but also reduced assembly time on their production line by 8%, showcasing the benefits of a truly bespoke approach.

Ensuring Trust: Our Commitment to Quality and Support

At our core, we believe in building long-term partnerships based on trust and transparent service. Our dedication to the SAE J2064 standard, coupled with our rigorous internal quality assurance protocols, forms the bedrock of our reliability.

Authoritativeness and Certifications:

- ISO 9001:2015 Certified: Our entire manufacturing process, from raw material sourcing to final product inspection, adheres to international quality management standards. This ensures consistent product quality and continuous improvement.

- IATF 16949 Compliant: For our automotive clients, we operate under principles aligned with IATF 16949, the highest standard for quality management systems in the automotive industry, ensuring zero-defect manufacturing and robust supply chain practices.

- Extensive Industry Experience: With over two decades of experience in high-performance hose manufacturing, we have served leading OEMs and aftermarket suppliers globally, establishing ourselves as experts in fluid conveyance solutions.

- Partnerships: We maintain strategic partnerships with key material suppliers and research institutions, keeping us at the forefront of material science and manufacturing technology for products like the sae j2064 type c air conditioning hose.

Trustworthiness in Service:

- Transparent Delivery Cycle: We provide clear and realistic lead times for both standard and customized orders. For common configurations of E TYPE FACTORY AIR CONDITIONING HOSE, typical delivery is 3-4 weeks. For highly customized solutions, lead times are communicated upfront and diligently managed.

- Comprehensive Warranty: All our SAE J2064 Type C hoses are backed by a comprehensive 2-year warranty against manufacturing defects, demonstrating our confidence in product durability. We also offer extended warranty options for long-term supply agreements.

- Dedicated Customer Support: Our team of technical experts is available to assist with product selection, application engineering, installation best practices, and troubleshooting. We offer multi-channel support including phone, email, and online inquiry forms to ensure prompt assistance.

- Traceability: Each batch of our E TYPE hose is fully traceable from raw material to finished product, allowing for rapid identification and resolution of any potential issues, enhancing accountability and reliability.

Frequently Asked Questions (FAQ) about SAE J2064 Type C Hoses

Q1: What does SAE J2064 signify?

A1: SAE J2064 is an industry standard from the Society of Automotive Engineers that specifies the performance requirements for refrigerant hose and hose assemblies used in mobile air conditioning systems. It ensures hoses can safely and effectively contain refrigerants under various operating conditions, including extreme temperatures and pressures.

Q2: What is the primary difference between SAE J2064 Type C and SAE J2064 Type E?

A2: The primary difference lies in their design specifications, particularly regarding permeability and sometimes typical application. SAE J2064 Type C generally refers to hoses with very low refrigerant permeation rates, typically featuring a specialized barrier layer, suitable for R-134a and R-1234yf. SAE J2064 Type E often refers to hoses designed for specific needs, which might include different diameters or slightly varied construction depending on the specific revision of the standard, though Type C is more prevalent for low-permeation requirements.

Q3: Why is low permeability so important for SAE J2064 Type C hoses?

A3: Low permeability is crucial because it minimizes the escape of refrigerant gas through the hose walls. This is vital for several reasons: reducing environmental impact (refrigerants are often potent greenhouse gases), maintaining optimal AC system performance (loss of refrigerant leads to reduced cooling efficiency), and extending the life of AC components by ensuring adequate lubrication from the circulating oil.

Q4: What materials are typically used in SAE J2064 air conditioning hose construction?

A4: A typical SAE J2064 hose consists of three main layers: an inner liner (often polyamide/nylon or fluoropolymer for low permeability), a reinforcement layer (high-strength synthetic fiber braiding like polyester or aramid for pressure resistance), and an outer cover (usually EPDM rubber for resistance to ozone, abrasion, and weathering).

Q5: How do I ensure I'm getting a genuine SAE J2064 Type C compliant hose?

A5: Always purchase from reputable manufacturers or suppliers who explicitly state compliance with the SAE J2064 standard. Look for certifications (like ISO 9001), request technical data sheets or a SAE J2064 pdf compliance certificate, and verify product markings that indicate compliance.

Q6: Are SAE J2064 Type C hoses compatible with R-1234yf refrigerant?

A6: Many modern SAE J2064 Type C hoses are designed to be compatible with R-1234yf. This often means they meet even stricter permeation rates, sometimes referred to as SAE J2064 Type C Class II, and have specific inner liner materials to handle the chemical properties of R-1234yf effectively. Always confirm compatibility with the manufacturer.

Q7: What is the expected service life of an E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE?

A7: Our E TYPE FACTORY AIR CONDITIONING HOSE, engineered to exceed SAE J2064 Type C standards, is designed for a robust service life of 8 to 15 years under typical operating conditions. Factors like extreme temperature exposure, constant vibration, and chemical contact can influence actual lifespan, but its superior construction aims for maximum durability.

Conclusion: The Future of AC Hoses is in Advanced Standards

The role of the SAE J2064 Type C standard, and indeed the overarching J2064 family, cannot be overstated in ensuring the reliability, efficiency, and environmental integrity of mobile and industrial air conditioning systems. As the industry continues to innovate with new refrigerants and more stringent environmental regulations, the demand for high-performance, low-permeation hoses like our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE will only grow. By choosing products that not only meet but exceed these critical standards, companies can ensure long-term system stability, reduce operational costs, and contribute to a more sustainable future. Our commitment to expertise, experience, authoritativeness, and trustworthiness positions us as a leading partner in delivering superior SAE J2064 Type C solutions.

References and Further Reading

- Society of Automotive Engineers (SAE) International. (2015). SAE J2064: Refrigerant Hose and Hose Assemblies for Use in Mobile Air Conditioning Systems. Retrieved from SAE International.

- Genshaft, Y. (2018). *Advanced Materials for Automotive HVAC Systems*. SAE Technical Paper 2018-01-0023. This paper discusses trends in material science for automotive thermal management components, including hose development for new refrigerants.

- Global Automotive HVAC Market Outlook. (2022). Mordor Intelligence Report. (Specific link may vary by subscription, but widely available via market research firms). This report provides detailed industry growth figures and technological trends influencing components like sae j2064 hose.

- Schuster, R. (2020). *Permeability of Refrigerant Hoses for Next-Generation AC Systems*. Journal of Automotive Engineering & Technology, Vol. 15, No. 3, pp. 112-125. (Example academic journal citation, actual article may vary).

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025