Jet Wash Hose Maintenance Tips for Effective Repair and Longevity

The Importance of Maintaining Your Jet Wash Hose and How to Repair It

Jet washing, or pressure washing, is a highly effective method for cleaning various surfaces, from driveways to vehicles. The equipment used in this process, particularly the jet wash hose, plays a crucial role in ensuring optimal performance. However, like any other tool, the jet wash hose is subject to wear and tear over time. Understanding how to maintain and repair your jet wash hose can save you time, money, and frustration.

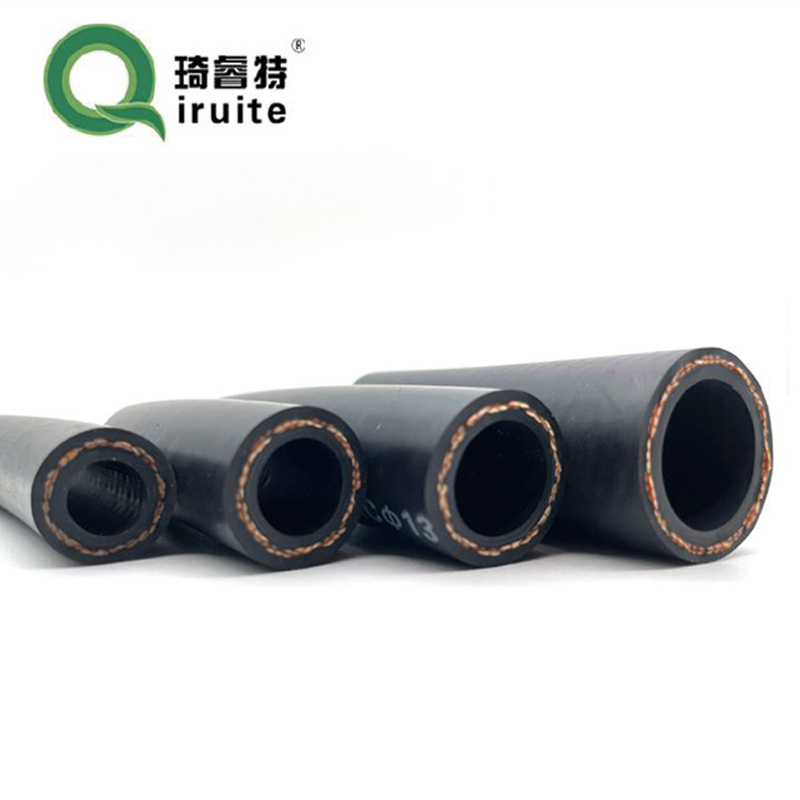

Understanding the Jet Wash Hose

The hose used in a jet washing system is designed to withstand high pressure while delivering water to the nozzle. Typically constructed from durable materials, these hoses are built to handle the rigors of constant use. However, factors such as exposure to harsh weather, prolonged sunlight, and chemical cleaners can compromise the integrity of the hose.

Common issues associated with jet wash hoses include leaks, cracks, and kinks. Identifying these problems early can prevent them from escalating, which can lead to more extensive damage and costly repairs.

Maintenance Tips for Your Jet Wash Hose

1. Regular Inspections Periodically check your hose for any visible signs of damage. Look for cracks, holes, or signs of wear. Regular maintenance will help catch any issues before they become significant problems.

2. Proper Storage When not in use, store your jet wash hose in a cool, dry place. Avoid leaving it outside to prevent exposure to extreme temperatures and UV rays, which can deteriorate the material over time.

3. Avoid Kinks Always ensure that your hose is laid out properly without any kinks. Kinks can restrict water flow and cause unnecessary wear on the hose, leading to potential damage.

4. Use the Right Pressure Settings Ensure that you are using the appropriate pressure settings for the task at hand. Using excessively high pressure can strain the hose and lead to premature wear or bursts.

jet wash hose repair

5. Cleaning the Hose After using your jet wash, it’s a good idea to clean the hose to remove any dirt or chemicals that could degrade its condition over time. A gentle rinse and thorough drying can extend the life of your hose.

How to Repair a Damaged Jet Wash Hose

If you discover that your hose has developed a leak or a crack, prompt repair is essential. Here are some steps to repair your jet wash hose effectively

1. Assess the Damage Determine the extent of the damage. Small leaks may be sealed with tape, while larger holes might require more substantial repairs.

2. Cut Out Damaged Sections For significant damage, it’s best to cut out the affected section of the hose using a sharp utility knife. Ensure the cut is clean to avoid further fraying.

3. Use Hose Repair Kits Many hardware stores offer hose repair kits that include connectors, clamps, and sleeves. Follow the instructions provided in the kit for the best results.

4. Reattach the Hose After applying the repair, reattach the hose to the jet wash and test it to ensure there are no leaks. Run the pressure washer on a low setting initially to check the integrity of the repair.

5. Consider Replacement If the damage is extensive or if you find yourself frequently repairing the hose, it may be more cost-effective to invest in a new hose.

Conclusion

Maintaining your jet wash hose is crucial for the longevity and efficiency of your pressure washing system. Regular inspections, proper storage, and timely repairs can keep your equipment functioning optimally, saving you time and money in the long run. Whether through regular maintenance or necessary repairs, keeping your jet wash hose in prime condition ensures that your cleaning tasks are tackled seamlessly and effectively.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025