SAE J1401 Brake Hose Specifications | DOT-Certified, Durable

SAE J1401 Brake Hose: What Matters, What’s Changing, and What to Ask Your Supplier

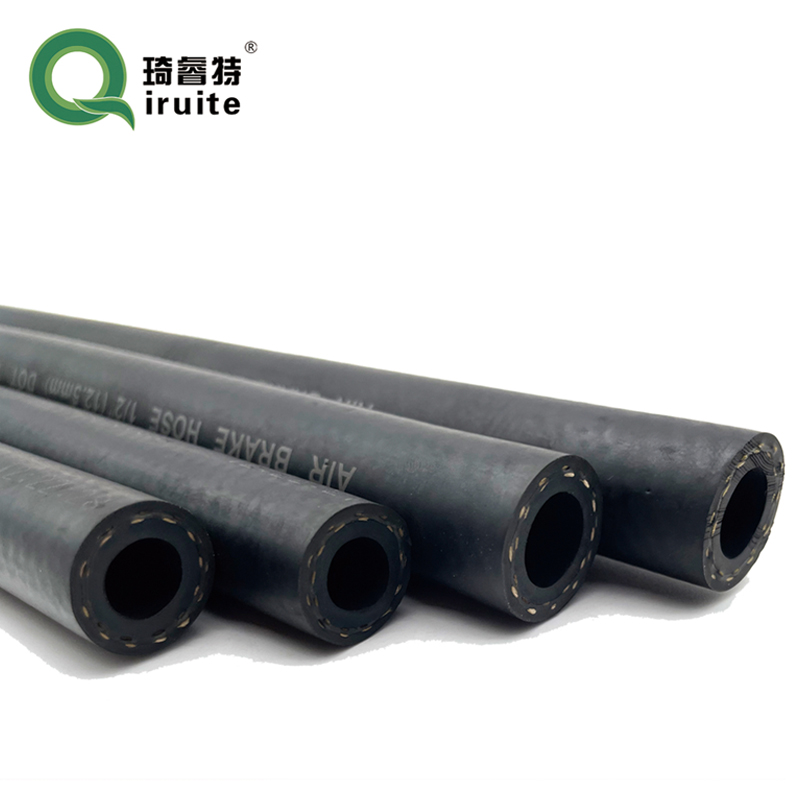

If you’re serious about brake system reliability, you’ve probably hunted for sae j1401 brake hose specifications more than once. Same here. I spend an unhealthy amount of time reading lab reports, and—oddly enough—talking to mechanics in truck yards. The Product Name is SAE J1401 Brake Hose, made in Ningjin County, Hebei Province. It’s built for hydraulic brake systems on autos, trucks, and trailers, typically using braided polyester or nylon over an EPDM tube. Simple idea, complex consequences.

Industry pulse: stricter testing, faster customization

Lately, buyers want tighter volumetric expansion, better low-temp flexibility, and cleaner batches (less extractables contaminating DOT 3/4/5.1 fluid). OEMs also push for IATF discipline. And yes, lead times matter—especially for service kits. In fact, many customers say they’ll trade a fancy sleeve for a hose that holds up in whip testing at -40°C. Fair.

Key specs at a glance

Below is a compact snapshot. Real-world use may vary with temperature, routing, fittings, and crimp quality. Later, I’ll circle back to sae j1401 brake hose specifications and what to scrutinize in the lab data.

| Parameter | Typical Range (≈) | Test Method / Standard |

|---|---|---|

| Inner tube | EPDM (brake-fluid compatible) | SAE J1401 material compatibility |

| Reinforcement | Braided polyester/nylon | Per spec construction |

| Working pressure | ≈ 10–15 MPa (≈1500–2200 psi) | SAE J1401 / FMVSS 106 |

| Burst pressure (min) | ≥ 55–70 MPa (≈8000–10000 psi) | Hydrostatic to rupture |

| Volumetric expansion | Tight control; typically ≤ spec at rated pressure | SAE J1401 expansion test |

| Temperature range | ≈ -40°C to +120°C (peaks higher briefly) | Low-temp flex / heat aging |

| Service life | 5–8 years typical; duty dependent | Field data + aging tests |

Process flow (how it’s actually made)

- Materials: EPDM inner/outer tube; braided polyester/nylon reinforcement; zinc-plated or stainless fittings.

- Methods: inner tube extrusion → braiding → outer cover extrusion → vulcanization → cutting → crimping → 100% pressure proof test.

- Testing: burst, whip (dynamic flex), ozone, leakage, expansion, salt spray on fittings, low-temp bend.

- Certs commonly requested: ISO 9001, IATF 16949 quality systems; sometimes ISO 14001 for environmental management.

Applications and customization

Use cases: passenger cars, heavy trucks, trailers, buses, motorcycles, even off-road kits. Custom options include bore sizes (≈3.2 mm, 4.8 mm), fittings (banjo, male/female), protective sleeves, and private labeling. For projects with tight response, ask for their last three lab reports tied to sae j1401 brake hose specifications—you’ll learn a lot.

Vendor snapshot (what buyers compare)

| Vendor | Lead Time | MOQ | Customization | Certs |

|---|---|---|---|---|

| QRT (Ningjin, Hebei) | ≈ 2–4 weeks | Flexible | Fittings, sleeves, lengths | ISO 9001; IATF on request |

| European Tier-2 | ≈ 4–6 weeks | Medium | Strong engineering support | IATF 16949 common |

| Generic Importer | Stock-based | Low | Limited | Varies |

Field notes and test snippets

- Random batch test: burst averaged ≈ 62 MPa; expansion stayed within the curve up to 10 MPa. To be honest, that’s what you want to see.

- Cold whip: no leakage after cycles at -40°C, fittings intact, light surface checking after ozone—still within spec.

- Customer feedback: “Pedal feel stayed consistent after a summer of towing”—not scientific, but it aligns with the data.

What to ask before you buy

- Latest lab reports aligned to sae j1401 brake hose specifications and FMVSS 106.

- Crimp specs and fitting material (coating, salt-spray hours).

- Traceability: heat/batch numbers on labels; warranty terms.

Authoritative citations

- SAE International, SAE J1401: Road Vehicle—Hydraulic Brake Hose Assemblies.

- NHTSA, FMVSS No. 106: Brake Hoses (49 CFR §571.106).

- IATF 16949:2016 – Automotive Quality Management System Requirements.

- ISO 14001:2015 – Environmental Management Systems.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025