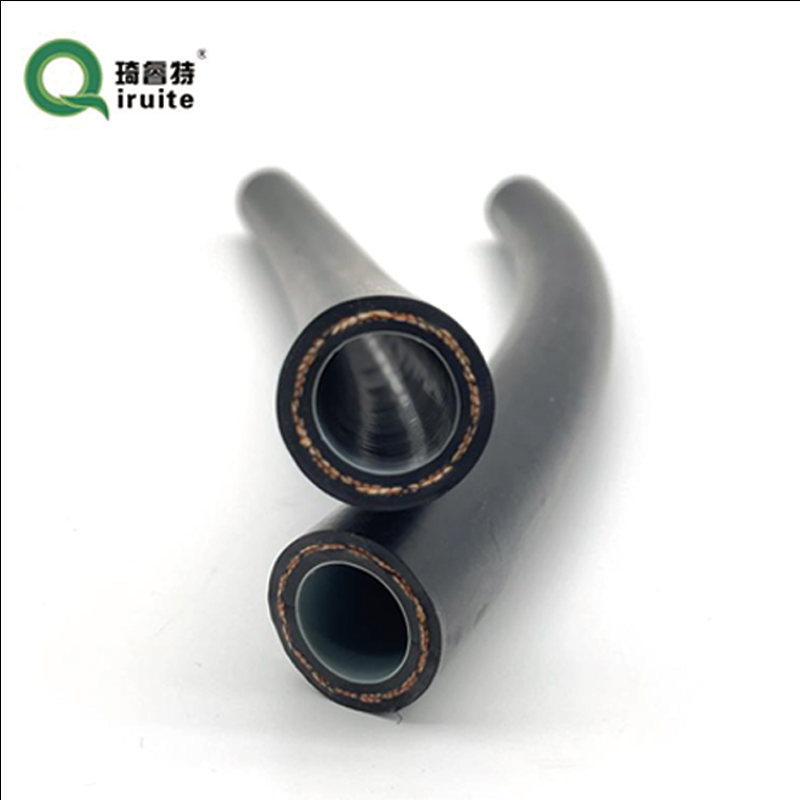

SAE J2064 Type C Class II Hose – Low Permeation, OEM-Grade

What’s Really Inside Sae J2064 Type C AC Hoses: Field Notes, Specs, and Buyer Tips

If you work around mobile HVAC, you’ve heard the debates. Barrier layer or not? Nylon or EVOH? To be honest, the conversation gets lively. Here’s the short version: Sae J2064 Type C is the classic low-permeation barrier hose spec many fleets still ask for. Interestingly, a new wave of “Type E” constant-pressure hoses—like the E Type models made in Ningjin County, Hebei Province—has been stealing the show with stronger, more uniform performance. I’ve been on shop floors where both run side by side; surprisingly, the field feedback isn’t as black-and-white as the spec sheets.

Industry trend snapshot

As systems transition from R134a to R1234yf (and, in EVs, into more complex thermal loops), engineers are asking for tighter permeation control, broader chemical compatibility, and stable working pressure across sizes. That’s where Type E designs shine. Still, Sae J2064 Type C remains widely specified by OEM drawings and many service bulletins, especially in retrofit programs.

Typical technical specs (Type C reference)

| Parameter | Baseline for Sae J2064 Type C (≈, real-world may vary) |

|---|---|

| Working pressure | ≈ 2.8–3.5 MPa depending on size |

| Burst pressure | ≥ 4× working pressure (typ.) |

| Permeation (R134a at 40 °C) | Low single-digit g/m²/day range, per SAE J2064 method |

| Temperature range | ≈ −40 °C to +125 °C |

| Construction | EPDM/HNBR tube, PA (nylon) barrier, textile reinforcement, EPDM cover |

Note: the E Type hose from Ningjin offers a constant 3.5 MPa across sizes—engineers like the predictability when mixing IDs on complex systems.

Vendor comparison (quick take)

| Vendor / Model | Construction | Key rating | Where it fits |

|---|---|---|---|

| Ningjin E Type (meets SAE J2064 Type E) | Barrier hose, textile braid, constant WP | 3.5 MPa constant | Mixed-ID systems; fleets wanting uniform specs |

| Typical Sae J2064 Type C from major brands | PA barrier, EPDM cover | ≈ 2.8–3.5 MPa | Legacy drawings; cost-sensitive retrofits |

| Premium Type E alternatives | Enhanced barrier, impulse-rated | High impulse durability | EV thermal loops; low-permeation targets |

Materials, process, and tests

Materials: HNBR/EPDM inner tube for oil and refrigerant, PA (nylon) barrier, PET/aramid braid, EPDM cover with ozone inhibitors. Methods: multi-layer co-extrusion, braiding, vulcanization, cut-to-length, crimp qualification. Tests (per SAE J2064): helium or R134a permeation, burst, proof, impulse cycles (often >150k), ozone (no cracks after 96 h at 40 °C), low-temp bend (−40 °C). Service life in fleet use: around 8–12 years, though duty cycle and routing matter a lot.

Applications and advantages

Where Sae J2064 Type C still fits: traditional automotive A/C, buses, off-highway, and retrofits on R134a and R1234yf with approved oils. Advantages: dependable barrier performance, easy crimping, good bend radius. Many customers say it’s the “safe pick” when drawings are frozen.

Customization and field notes

Options typically include IDs from 5/16" up to 1", custom branding, cover colors, and matched fittings. In fact, one EV startup told me a Type E constant-pressure hose simplified validation because burst margins were consistent across all lines. Conversely, a city bus operator stuck with Sae J2064 Type C to mirror legacy spares—and reported leak rates dropped ≈18% after re-routing and re-crimp training. It seems process discipline matters as much as the hose spec.

Certifications and compliance

Look for IATF 16949/ISO 9001 quality systems, ISO 14001 environmental management, and material compliance (REACH/RoHS). Always verify refrigerant/oil compatibility with manufacturer data before sign-off.

Bottom line

If your spec requires Sae J2064 Type C, you’re covered—just validate permeation and impulse for your duty cycle. If you’re free to optimize, Type E constant 3.5 MPa hoses from Ningjin County are worth a serious look for mixed-diameter systems and EV thermal needs.

- SAE International. SAE J2064: R-134a, R-1234yf Refrigerant Automotive Air-Conditioning Hose Requirements.

- ASHRAE Handbook—Refrigeration: Properties and application guidance for R134a/R1234yf.

- IATF. IATF 16949 Automotive Quality Management Standard.

- ISO. ISO 14001 Environmental Management Systems.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025