SAE J2064 Type C: Low-Permeation, Durable A/C Hose?

What Buyers Really Need to Know About sae j2064 type c Hoses (and Why Type E Is Winning)

If you work with mobile A/C lines, you’ve heard the debates: do we spec classic sae j2064 type c barrier hose or jump to ultra‑low permeation Type E? To be honest, it’s not just semantics. It’s about leak rates, refrigerant choices (R‑134a vs. R‑1234yf), and how fleets survive brutal summers without a comeback job.

Trend check: from Type C to Type E

In most editions of SAE J2064, Type C generally refers to barrier hose constructions suited to R‑134a systems; Type E pushes further—multilayer designs aimed at ultra‑low permeation, especially with R‑1234yf. Many customers say their leak‑related top‑ups dropped noticeably when switching to Type E. Not shocking—OEMs are squeezing grams-per-year emissions, and sustainability teams are watching.

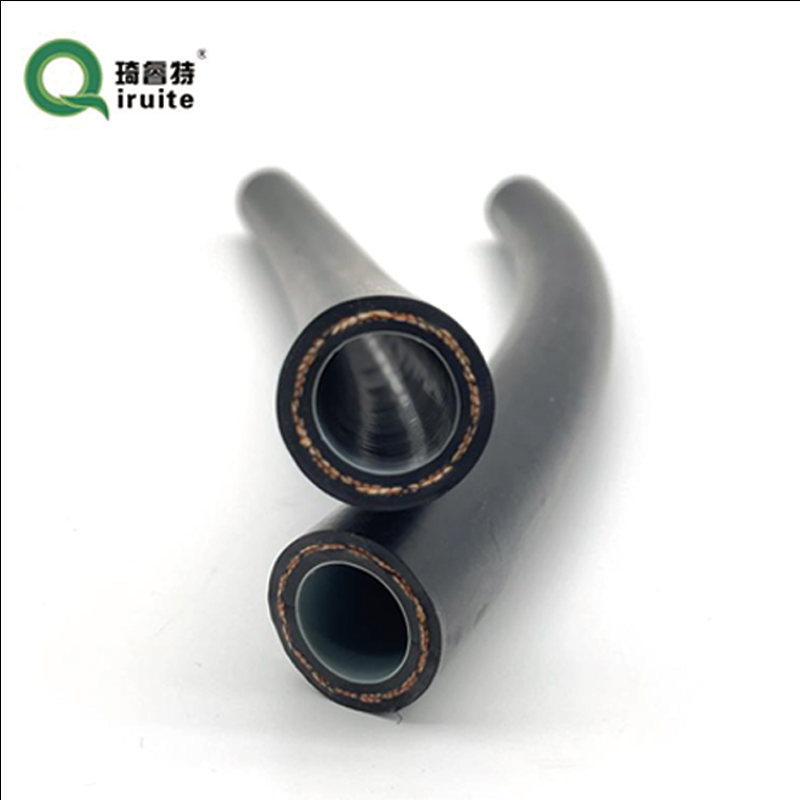

Product spotlight: E Type Factory Air Conditioning Hose with Good Performance

Origin: Ningjin County, Hebei Province. This E Type hose keeps a constant working pressure of 3.5 MPa across all sizes and is engineered to meet SAE J2064 Type E performance. It’s designed for today’s ultra‑low permeation expectations while remaining drop‑in compatible with standard A/C assemblies. If you’ve historically specified sae j2064 type c, this is the modern counterpart many purchasing teams are shortlisting.

| Spec (≈ real-world) | E Type Hose |

|---|---|

| Working Pressure | 3.5 MPa (constant, all sizes) |

| Permeation Class | Meets SAE J2064 Type E targets; Class I–II typical, application‑dependent |

| Temp Range | ≈ −40°C to +125°C (peaks to +135°C) |

| Burst Pressure | ≥ 4× WP per SAE methods (size‑dependent) |

| Compatible Refrigerants | R‑134a, R‑1234yf; common oils (PAG/POE) with validation |

How it’s made (short version)

- Materials: inner tube EPDM/NBR blend; PA (nylon) or multilayer barrier; reinforcement with polyester braid; EPDM outer cover.

- Methods: precision extrusion → barrier co‑extrusion/liner → braiding → vulcanization → cut/mark → 100% visual + sampling tests.

- Testing: SAE J2064 permeation, pressure (static/burst), flex/impulse (SAE J343 methods), temperature cycling, oil compatibility, salt/fog exposure.

- Service life: around 8–12 years in typical fleets; harsher duty may shorten—spec the routing carefully.

- Industries: passenger cars, buses/coaches, ag & construction, refrigerated vans, EV heat‑pump loops.

Why buyers move from sae j2064 type c to Type E

Lower leak rates (grams/year), better retention for R‑1234yf, and slightly tighter bend/flex performance in many sizes. In fact, some techs report fewer callbacks after heat‑soak summers—anecdotal, yes, but consistent.

Sample test snapshots (representative)

Permeation: ≈ 2–6 g/yr per connection equivalent on bench rigs using SAE J2064 protocols; burst ≥ 14 MPa for mid‑sizes; impulse 150k+ cycles at 120°C (lab). Real‑world use may vary.

Vendor comparison (quick buyer’s view)

| Vendor | MOQ | Lead Time | Customization | Certs (claimed) | Price Tier |

|---|---|---|---|---|---|

| Ningjin manufacturer (Type E spotlight) | ≈ 500–1,000 m | 3–5 weeks | ID/OD, print, color stripe, cut‑to‑length | ISO 9001/IATF 16949 (request proof) | Value |

| Global Brand A (Type C & E) | Low | Stock–4 weeks | Limited custom SKUs | IATF 16949, ISO 14001 | Premium |

| Specialist Hose Shop B | By the meter | Immediate | Assembly, fittings | Supplier declares RoHS/REACH | Mid |

Customization tips

- Dial in ID/OD for crimp spec; request crimp charts.

- Choose barrier architecture for refrigerant (R‑1234yf likes Type E).

- Ask for salt‑spray fittings and UV‑resistant cover for coastal fleets.

Two quick case notes

Coach fleet (humid, coastal): Type E swap cut seasonal top‑ups ≈ 30% year‑over‑year. EV startup: tighter routing with smaller bend radius reduced assembly weight ≈ 8% without NVH complaints.

Compliance and documentation

Request: SAE J2064 test reports, material declarations (RoHS/REACH), and quality certificates (ISO 9001/IATF 16949). For safety, check SAE J639 guidance; for emissions benchmarks, see SAE J2727. Some buyers also align with ISO 14001 policies.

References:

- SAE J2064: Refrigerant Automotive Air‑Conditioning Hose and Hose Assemblies. SAE International.

- SAE J639: Safety Standards for Motor Vehicle Refrigerant Systems. SAE International.

- SAE J2727: HFC‑134a (R‑134a) Mobile Air‑Conditioning System Emission Chart. SAE International.

- U.S. EPA SNAP and low‑GWP refrigerant guidance for MAC systems.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025