Need a High-quality power steering tube that’s leak-proof?

Why a high-quality power steering tube still matters in 2025

If you maintain fleets or just love a tight steering feel, you’ll care about the High-quality power steering tube coming out of Ningjin County, Hebei Province. I’ve toured enough hose and tube lines to know: the devil is in the metallurgy, surface finish, and crimp integrity. And, to be honest, in the testing regime. Many customers say they only notice the steering line when it fails—leaks, whine, dead spots. This is how you avoid that.

Industry snapshot

Even with EPS on newer platforms, hydraulic assist remains entrenched in work trucks, buses, and legacy passenger cars. The trend I’m seeing: corrosion-robust coatings (Zn–Ni), tighter NVH targets, and compatibility with bio-based or low-vis fluids. Another quiet trend—longer warranties—demands tubes that survive harsher heat/cold cycles and road salt exposure.

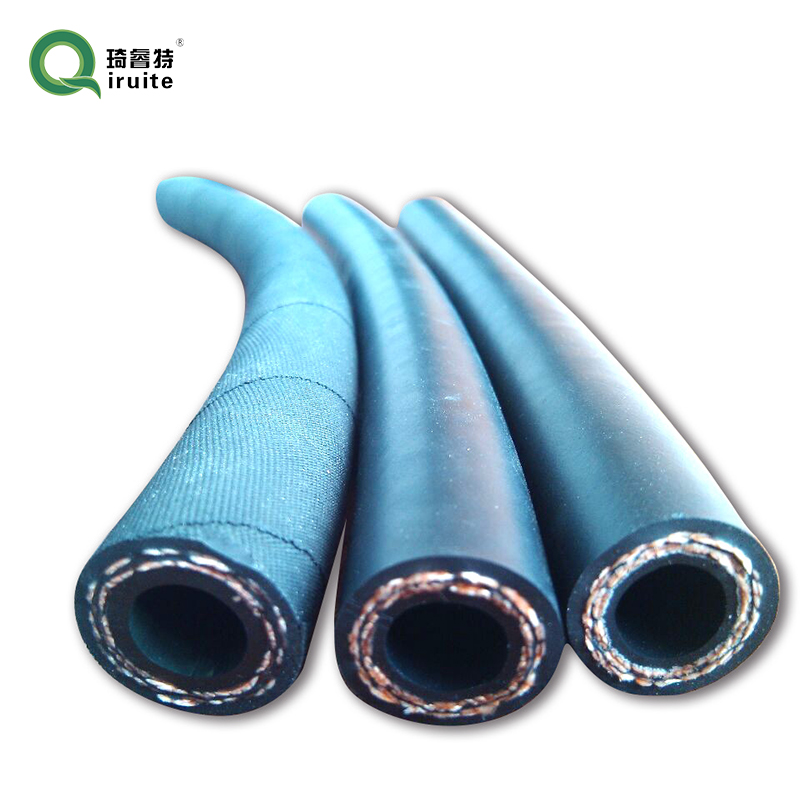

What’s inside the tube (and why it matters)

- Base tube: low-carbon precision steel or 6061-T6 aluminum, CNC-bent with ≤ ±0.5° angle tolerance.

- Joints: TIG/brazed or crimped to elastomer sections (NBR/EPDM blend) for vibration isolation.

- Coating: Zn–Ni plating (optional e-coat) targeting ≥ 480 h ASTM B117 salt spray.

- End forms: banjo, flare (e.g., 45°), quick-connects; common threads M14×1.5/M16×1.5.

| Spec | Typical value (≈, real-world may vary) |

|---|---|

| Working pressure | 10–14 MPa (1,450–2,030 psi) |

| Burst pressure | ≥ 3× working (≈ 30–42 MPa) |

| Temperature range | −40 to +150 °C (short peaks +155 °C) |

| Impulse durability | ≥ 150k cycles @ 120 °C per ISO 6803/SAE J343 |

| Service life | Up to 200,000 km or 8–10 years (duty-dependent) |

Process flow and testing

Materials are incoming-inspected (chemistry, hardness), CNC bent, end-formed, and brazed/crimped. Every assembly is 100% helium or air-under-water leak tested; lots are impulse and burst tested per SAE J2050/J343. Coatings are verified via ASTM B117; elastomers are screened for REACH/RoHS. IATF 16949 and ISO 9001 systems keep traceability tidy.

Where it fits

Passenger cars, light trucks, buses, forklifts, and ag machines. Urban fleets like the smoother feel and—surprisingly—the quieter pump noise when a properly tuned line is used. The High-quality power steering tube is also a straightforward retrofit in corrosion-prone coastal regions.

Advantages you can feel

- Leak resistance via tight crimp windows and end-form geometry.

- Corrosion resilience (Zn–Ni); tested to 480–720 h NSS.

- NVH tuning reduces pump whine and steering nibble at idle.

- Easy install: OE-matched routing and brackets, clear port labeling.

| Vendor | Coating & corrosion | Testing scope | Warranty |

|---|---|---|---|

| QRT (High-quality power steering tube) | Zn–Ni, 480–720 h NSS | 100% leak + impulse/burst by lot | 24–36 months |

| Generic import | Basic Zn, ≈ 120–240 h | Sampling only | 6–12 months |

| Tier-1 OEM | Zn–Ni/e-coat, 480+ h | Full PPAP, bench/vehicle | 12–24 months |

Customization and real-world wins

Options include geometry tweaks, bespoke brackets, thread types, coatings, and private labeling. A coastal taxi fleet saw leak claims drop by ≈ 70% after switching to the High-quality power steering tube. In a cold-climate bus operator trial, steering feel at −30 °C was noticeably steadier—driver feedback was, frankly, glowing.

Certifications, compliance, and test data

Built under IATF 16949 and ISO 9001; compliant with RoHS and REACH. Typical lab data: 0 failures in 150k impulse cycles at 120 °C; burst margin ≥ 3×; no red rust at 480 h NSS. Actual results vary by geometry and fluid.

Closing thought

You don’t buy a steering tube for fun—you buy it to forget about it. This one makes that easy.

- SAE J2050: High-Temperature Power Steering Pressure Hose

- SAE J343: Test and Performance for Hydraulic Hose and Hose Assemblies

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus

- ISO 6803: Rubber or plastics hoses—Hydraulic pressure impulse test

- IATF 16949: Automotive Quality Management System; ISO 9001: Quality Management Systems

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025