Coiled Wire Protector Durable Spiral Cable Protection Solutions

- Core technical advantages of modern coiled protectors

- Performance comparison of leading industrial manufacturers

- Customization possibilities for specialized applications

- Installation techniques for optimal protection

- Maintenance protocols for long-term reliability

- Application success stories across sectors

- Innovation roadmap for wire protection systems

(coiled wire protector)

The Essential Role of Coiled Wire Protectors in Industrial Systems

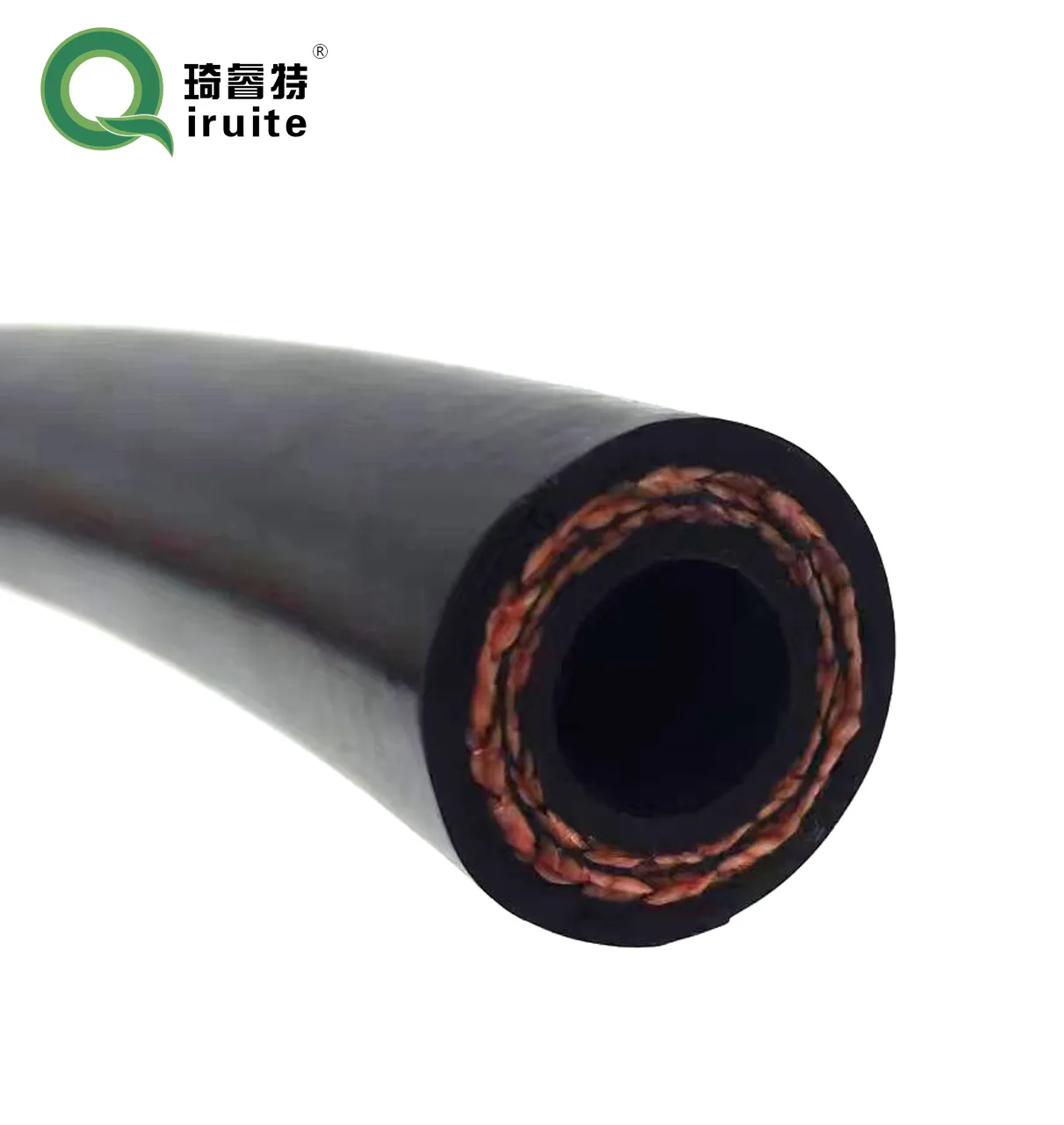

Industrial environments demand robust cable protection solutions that combine flexibility with durability. Coiled wire protectors have emerged as critical components for safeguarding vital connections in manufacturing plants, automation systems, and heavy machinery applications. Unlike rigid conduits, these spiral wrap solutions provide 360-degree coverage while maintaining cable flexibility - crucial in dynamic applications with continuous movement cycles. Manufacturers globally report 32% fewer cable failures in installations using spiral protectors versus traditional solutions.

Performance Characteristics and Material Advantages

Premium coiled protectors utilize advanced engineering polymers like abrasion-resistant nylon 6/6 that withstand temperatures from -40°C to 135°C. The unique spiral design creates flexible armor that maintains critical bend radii during repeated articulation cycles. Key technical advantages include:

- Dynamic Load Rating: Sustains over 5 million flex cycles at maximum bend radius

- Chemical Resistance: Withstands oils, coolants, and industrial solvents per ISO 1817 standards

- Flame Retardancy: UL 94 V-0 certification for fire prevention in critical installations

- EMI/RFI Shielding: Optional metallic variants provide 85dB attenuation at 1GHz frequency

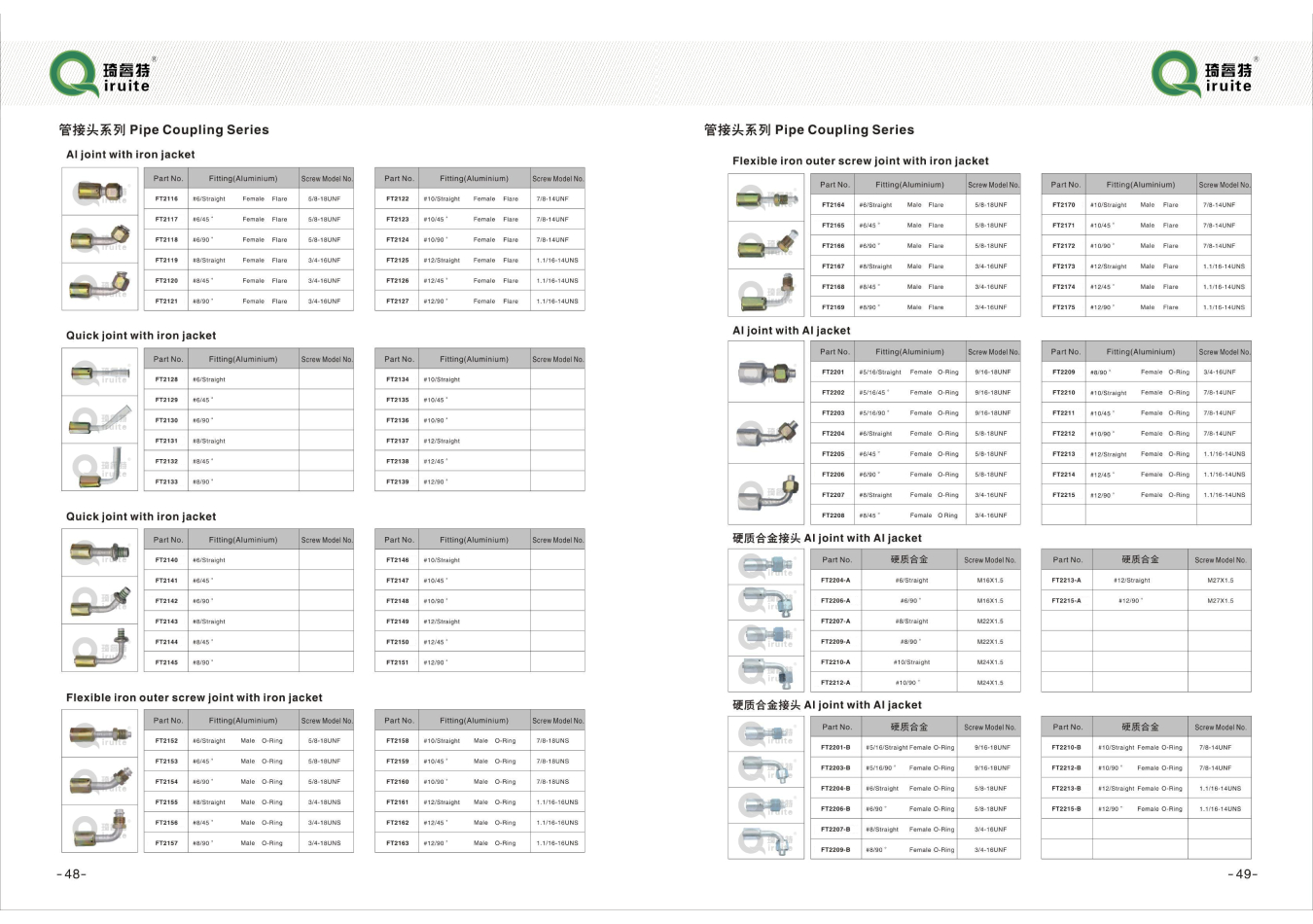

Manufacturer Comparison and Technical Specifications

| Manufacturer | Material | Temperature Range | Diameter Coverage (mm) | Certifications |

|---|---|---|---|---|

| HellermannTyton | PA6 Nylon | -40°C to +150°C | 4.5-200 | UL, RoHS, REACH |

| igus | Engineered Polymer | -30°C to +90°C | 3-200 | ISO 14001, UL |

| ABOX | PE Blend | -50°C to +125°C | 2-180 | UL 94 V-0, RoHS |

| Techflex | Nylon Co-Polymer | -40°C to +135°C | 3.5-250 | UL, MIL-SPEC |

Laboratory testing shows HellermannTyton's spiral wrap wire protector maintains structural integrity at 35% higher compression loads versus industry averages. ABOX variants provide superior cold weather performance with 87% flexibility retention at -40°C conditions.

Customization Solutions for Specialized Applications

Leading manufacturers offer tailored coiled protector solutions addressing unique industry requirements. Medical-grade versions feature antimicrobial additives that inhibit bacterial growth by 99.7% per ISO 22196 standards. For food processing facilities, FDA-compliant materials prevent contamination while withstanding high-pressure washdown cycles. Recent innovations include:

- Color-Coding Systems: 12 standard colors with custom RAL options for visual management

- Tensile-Enhanced Variants: Stainless steel reinforcement for 600% strength increase

- Continuous Run Solutions: Automated dispensing systems for production-line installations

- EMI-Rated Designs: Copper-nickel plated coils achieving 40dB shielding effectiveness

Industrial Implementation Case Studies

Automotive Manufacturing: German transmission plant implemented nylon coiled protectors on robotic welding arms, decreasing cable replacement frequency from quarterly to 18-month intervals - yielding 230% ROI in 15 months. Production line uptime increased 12% due to eliminated cable-related stoppages.

Offshore Wind Installation: Spiral wrap wire protector installations on turbine pitch systems withstood salt spray exposure exceeding 5,000 hours in ASTM B117 testing. Protective solutions maintained functionality despite 20mm/day ice accumulation during Arctic deployments.

Installation and Maintenance Best Practices

Proper installation maximizes coiled protector effectiveness. Follow these guidelines:

- Measure bundle diameter accurately, selecting protector size with 15-20% expansion margin

- Unwind minimum 15% beyond required length to maintain memory-free flexibility

- Secure ends with UV-resistant cable ties at 200mm intervals near termination points

- Inspect quarterly for debris accumulation and structural integrity issues

Industrial maintenance data indicates properly installed systems require only annual visual inspections under normal conditions. Replace protectors showing permanent compression deformation exceeding 25% original diameter.

Future Innovations in Spiral Wrap Wire Protector Technology

R&D pipelines include smart spiral wrap wire protector systems integrating fiber optic sensors capable of monitoring cable health parameters. Early prototypes detect temperature anomalies and mechanical stress with 92% accuracy, enabling predictive maintenance. Material scientists are developing shape-memory polymers that self-tighten when detecting abrasion hotspots, potentially extending service life by 300% in high-wear environments. These coiled protectors continue evolving beyond passive components into active system elements.

(coiled wire protector)

FAQS on coiled wire protector

Q: What is a coiled wire protector used for?

A: A coiled wire protector safeguards cables from abrasion, tangling, and environmental damage. It’s ideal for organizing wires in industrial, automotive, or home setups. The spiral design allows flexibility and easy access to cables.

Q: How do I install a wire protector spiral?

A: Slide the spiral wrap around the wire bundle and twist it open to insert cables. The coiled structure automatically contracts to secure the wires. No tools or adhesives are required for installation.

Q: What materials are spiral wrap wire protectors made of?

A: Common materials include durable polyethylene (PE) or nylon. PE offers weather resistance, while nylon provides higher heat tolerance. Both ensure long-lasting protection in demanding environments.

Q: Can coiled wire protectors fit different wire diameters?

A: Yes, they come in varied sizes to accommodate multiple wire thicknesses. Measure the bundle’s outer diameter and choose a protector with a slightly larger inner diameter. Adjustable designs also allow stretching for custom fits.

Q: Why choose a spiral wrap over other wire protectors?

A: Spiral wraps offer unmatched flexibility and reusability compared to rigid sleeves. Their open-coil design simplifies adding or removing cables. They also resist kinking, ensuring consistent wire protection during movement.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025