SAE J1401 Brake Hose Specifications | DOT Approved, Durable

SAE J1401 Brake Hose: What Specs Really Matter in the Field

If you’ve ever stood in a workshop arguing about brake feel, expansion, or whip resistance (guilty), you know the spec sheet tells only half the story. This guide unpacks sae j1401 brake hose specifications from a practical, boots-on-the-ground perspective—what engineers ask for, what fleet managers check, and what actually holds up on the road.

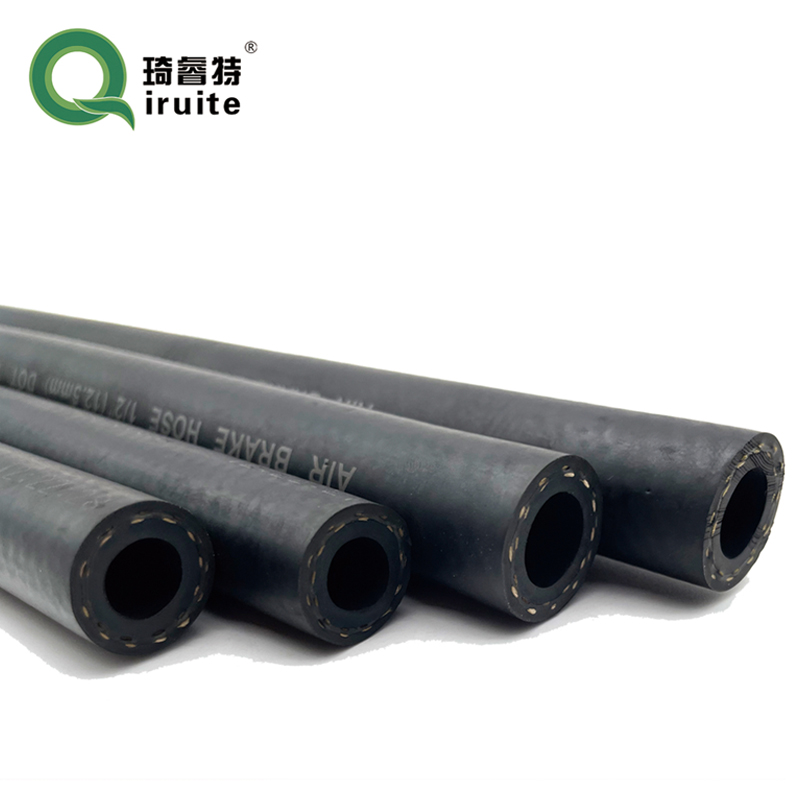

Product snapshot and where it comes from

Product: SAE J1401 Brake Hose (aka “oil brake hose” in some catalogs). Origin: Ningjin County, Hebei Province. It’s designed for hydraulic pressure transmission in automotive, truck, and trailer braking systems. Construction typically uses a synthetic rubber tube with high-quality braided polyester or nylon reinforcement and a weather/ozone-resistant cover. Sounds standard—until you get into the testing.

Quick spec table (typical values)

| Parameter | Typical Range / Note |

|---|---|

| Inner diameter | ≈ 3.2–10 mm (common: 3.2, 4.8, 6.3 mm) |

| Working pressure | ≈ 10–15 MPa (1,450–2,175 psi), real-world use may vary |

| Proof pressure | ≥ 20.7 MPa (3,000 psi) per common lab practice |

| Burst pressure | ≥ 69 MPa (10,000 psi) typical to meet J1401/FMVSS 106 intent |

| Min. bend radius | ≈ 25–50 mm depending on size |

| Temperature range | -40°C to +120°C intermittent (glycol-based brake fluids) |

How it’s made (the short version)

- Materials: EPDM-based tube/cover for DOT 3/4/5.1 compatibility; braided polyester or nylon reinforcement; anti-ozone cover.

- Methods: Inner tube extrusion → high-tension braiding → outer cover extrusion → vulcanization → permanent marking (traceability) → 100% pressure test and cleanliness check.

- Testing: Burst, proof, whip (impulse flex), volumetric expansion, adhesion, ozone resistance, low-temp flexibility, salt-spray on fittings, cleanliness (ISO 16232 style), and aging.

Where it’s used and how long it lasts

Applications: passenger cars, light trucks, buses, trailers, motorcycles, specialty off-road. Service life: many fleets report 5–8 years under normal conditions; harsh climates, heavy load cycles, and chemical exposure can shorten that. To be honest, routing and clamp spacing matter as much as the hose brand.

Certifications and real test data

Compliant manufacturers cite SAE J1401 and FMVSS 106. Typical lab snapshots I’ve seen: burst > 10,500 psi; volumetric expansion ≈ 0.20–0.40 cm³/m at 1,000 psi; whip test passing 35 h at elevated temperature; ozone test no cracks at 50 pphm/40°C. Numbers vary by size and lot—always ask for a batch test report.

Vendor comparison (what buyers actually compare)

| Vendor | Standards | Lead time | Customization | Price level | Docs |

|---|---|---|---|---|---|

| QRT (Hebei, Ningjin) | SAE J1401, FMVSS 106 | ≈ 2–4 weeks | ID/OD, fittings, length, branding | Value | COC, batch test, PPAP on request |

| Vendor B (Tier supplier) | SAE J1401, OEM specs | ≈ 4–6 weeks | Extensive, incl. assemblies | Premium | PPAP, IMDS |

| Vendor C (Aftermarket) | SAE J1401 | Stock/quick ship | Limited options | Economy | Basic COC |

Customization tips

Ask for lot traceability printed on the cover, low-expansion constructions for performance models, and corrosion-resistant fittings (Zn-Ni or stainless). If you’re chasing ultra-steady pedal feel, tighter volumetric expansion targets matter more than catalog hype. That’s where sae j1401 brake hose specifications meets performance reality.

Mini case study

A regional bus fleet switched to a J1401 hose build with braided nylon reinforcement and stricter expansion limits. Over 12 months, warranty returns dropped ≈32%, and drivers reported “firmer, more consistent” pedal feel. Not scientific, but consistent with what many customers say. It seems attention to sae j1401 brake hose specifications—especially expansion and whip endurance—pays back fast.

Industry trend to watch

We’re seeing tighter cleanliness specs (think ABS/ESC valve sensitivity), more EPDM formulations optimized for new fluid chemistries, and a push toward digital traceability. Honestly, none of this is flashy—but it keeps vehicles stopping straight and predictably.

Authoritative references

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025