SAE J2064 Type C AC Hose: High-Performance & Durable

Understanding Industry Trends in Automotive AC Hoses

The automotive climate control industry is undergoing significant transformation, driven by demands for increased efficiency, environmental compliance, and enhanced durability. As vehicle electrification accelerates and refrigerants evolve, the specifications for critical components such as air conditioning hoses are becoming more stringent. The industry is moving towards solutions that offer superior impermeability to new refrigerants like R-1234yf, better resistance to higher operating pressures, and reduced weight for fuel economy improvements. This has put a spotlight on advanced hose designs and materials, particularly those conforming to rigorous international standards.

Emerging trends include the integration of multi-layer hose constructions to combat refrigerant permeation, the adoption of advanced elastomers for improved flexibility and chemical resistance, and the development of compact, low-profile designs to optimize engine bay packaging. Furthermore, sustainability is a growing concern, prompting manufacturers to explore recyclable materials and more eco-friendly manufacturing processes. The global push for lower carbon footprints and stricter emissions regulations means every component, including the sae j2064 type c hose, must contribute to the overall efficiency and environmental performance of the vehicle.

Technical Specifications of SAE J2064 Type C Hoses

The SAE J2064 standard outlines the performance requirements for refrigerant hose assemblies used in automotive air conditioning systems. Specifically, the sae j2064 type c designation refers to a hose designed for higher pressure and temperature applications, commonly found in modern R-134a and R-1234yf systems. These hoses are engineered to handle the demands of increasingly complex AC circuits, offering robust performance and durability over extended service life.

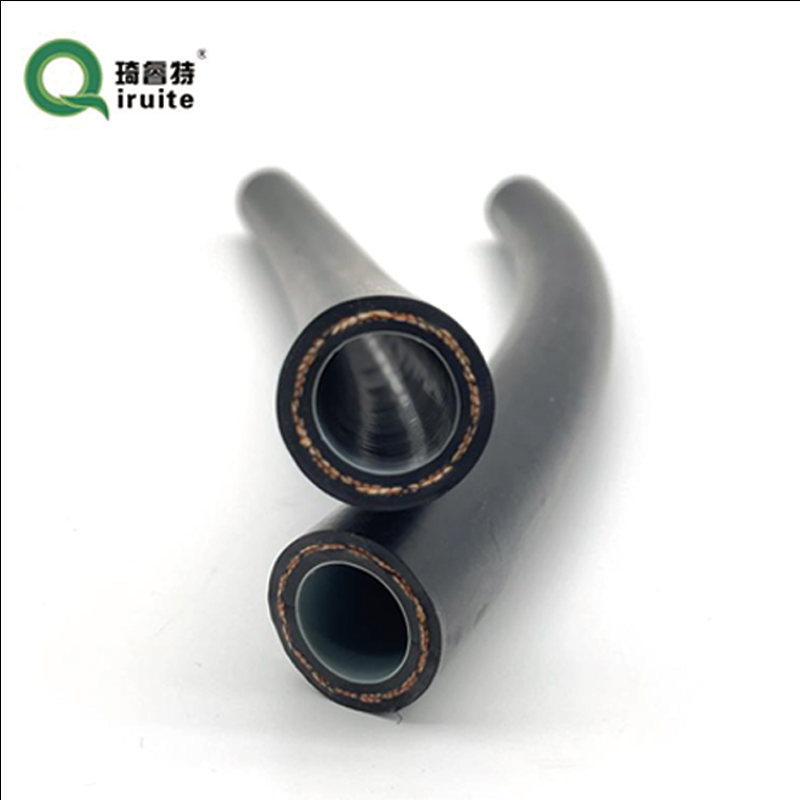

Key technical parameters for sae j2064 type c hoses include burst pressure resistance, permeation rates, cold flexibility, vacuum retention, and resistance to kinking and vibration. These hoses are typically multi-layered, often featuring an internal barrier layer (e.g., polyamide or nylon) to minimize refrigerant permeation, an EPDM or IIR (butyl rubber) inner tube, reinforcement layers (e.g., polyester braid), and an external cover for abrasion and ozone resistance. The specific sub-classification, such as sae j2064 type c class ii, further defines performance characteristics like permeation rates, which are critical for minimizing refrigerant loss and ensuring system efficiency.

Here's a generalized specification table reflecting typical performance parameters for an sae j2064 air conditioning hose:

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| Refrigerant Compatibility | R-134a, R-1234yf | SAE J2064 Appendix A |

| Working Pressure (Max) | Up to 3.5 MPa (500 psi) | SAE J2064 Section 5.3 |

| Burst Pressure (Min) | 17.5 MPa (2500 psi) | SAE J2064 Section 5.4 |

| Temperature Range | -40°C to +135°C | SAE J2064 Section 5.5 |

| Refrigerant Permeation Rate (R-134a) | < 0.25 kg/m²/year | SAE J2064 Section 5.8 |

| Cold Flexibility | No cracking at -40°C | SAE J2064 Section 5.9 |

| Ozone Resistance | No cracks after 72h @ 50pphm | SAE J2064 Section 5.10 |

The production of a high-performance sae j2064 type c hose involves a meticulous, multi-stage manufacturing process designed to ensure material integrity, structural robustness, and compliance with stringent performance standards. From raw material selection to final quality assurance, each step is critical.

1. Material Selection and Preparation

- Inner Tube (Elastomer): High-grade EPDM (Ethylene Propylene Diene Monomer) or IIR (Isobutylene Isoprene Rubber), selected for its excellent chemical resistance to refrigerants and oils, as well as its thermal stability. Materials are carefully compounded to achieve desired flexibility and low permeation.

- Barrier Layer (Thermoplastic): A thin layer of polyamide (PA) or nylon, often co-extruded, provides the primary barrier against refrigerant permeation. This is crucial for meeting sae j2064 pdf permeation requirements for R-134a and R-1234yf.

- Reinforcement (Fiber): High-tensile polyester or aramid fibers are commonly used. These are precisely braided or spiraled around the inner tube and barrier layer to provide burst strength and dimensional stability under pressure.

- Outer Cover (Elastomer): Typically EPDM or CSM (Chlorosulfonated Polyethylene) compounds, formulated for superior resistance to abrasion, ozone, UV radiation, and external chemicals in the engine bay environment.

2. Extrusion and Co-extrusion

The inner tube and barrier layer are often produced through co-extrusion. In this process, multiple extruders feed different material compounds simultaneously through a single die, creating a seamless, multi-layered core. This ensures excellent adhesion between layers and consistent wall thickness.

Schematic Step 1: Core Extrusion

[Hopper 1 (EPDM/IIR)] --> [Extruder 1] -->

[Hopper 2 (PA/Nylon)] --> [Extruder 2] --> [Co-extrusion Die] --> [Inner Tube + Barrier Layer]

3. Reinforcement Application

The extruded core then moves to braiding or spiraling machinery. High-speed textile machines precisely apply one or more layers of reinforcement fibers. The angle and tension of the fibers are meticulously controlled to achieve the desired pressure rating and flexibility characteristics of the sae j2064 hose.

Schematic Step 2: Reinforcement

[Inner Tube + Barrier Layer] --> [Braiding/Spiraling Machine (Polyester/Aramid)] --> [Reinforced Core]

4. Outer Cover Extrusion

A final layer of elastomer is extruded over the reinforced core to form the outer cover. This layer provides protection against environmental factors and mechanical damage, enhancing the overall service life of the j2064 hose.

Schematic Step 3: Outer Cover

[Reinforced Core] --> [Extruder (EPDM/CSM)] --> [Final Hose Profile (Uncured)]

5. Vulcanization (Curing)

The uncured hose is then subjected to a vulcanization process, typically in an autoclave or through continuous curing lines. Heat and pressure chemically cross-link the elastomer compounds, imparting the final physical properties, such as elasticity, strength, and resistance to temperature and chemicals. This step is critical for ensuring the hose meets the long-term durability requirements of the automotive industry.

6. Testing and Quality Control

Post-vulcanization, the hose undergoes rigorous testing. This includes dimensional checks (inner diameter, outer diameter, wall thickness), burst pressure testing (to ISO 1402 standards), permeation rate testing, cold flexibility, ozone resistance, and vibration endurance. Samples are taken from each batch to ensure compliance with SAE J2064, ISO, and client-specific standards. This adherence to strict testing standards ensures a reliable and durable product with an extended service life, typically exceeding 10 years in automotive applications.

Target industries for these hoses include automotive OEM manufacturing, aftermarket automotive parts, heavy-duty vehicle manufacturing, and specialized industrial refrigeration systems. Advantages in typical application scenarios include significant energy saving through minimal refrigerant leakage, superior corrosion resistance in harsh engine environments, and enhanced vehicle reliability. The robust construction ensures optimal performance even in challenging conditions, making the E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE a reliable choice.

Application Scenarios and Technical Advantages

The versatility and high performance of sae j2064 type c hoses make them indispensable across a variety of demanding application scenarios, primarily within the automotive and specialized industrial sectors. Their robust design, optimized for both R-134a and R-1234yf refrigerants, ensures reliable operation in critical systems.

Key Application Scenarios:

- Automotive OEM Assembly: Integrally used in the air conditioning systems of passenger cars, SUVs, light commercial vehicles, and heavy-duty trucks. They connect compressors, condensers, evaporators, and accumulators, forming the critical fluid transfer pathways.

- Commercial and Public Transportation: Essential for maintaining climate control in buses, trains, and specialized transport vehicles where passenger comfort and system reliability are paramount.

- Agricultural and Construction Equipment: Operating in harsh environments with extreme temperatures, dust, and vibration, these hoses provide durable air conditioning solutions for tractors, excavators, and other heavy machinery.

- Specialized Refrigeration Units: Beyond traditional automotive, they find use in mobile refrigeration units, refrigerated trailers, and certain industrial cooling applications that require high-pressure, low-permeation hose assemblies.

Technical Advantages:

- Superior Permeation Resistance: The multi-layer barrier design significantly reduces refrigerant escape, adhering to stringent environmental regulations and ensuring AC system efficiency over time. This minimizes the need for costly recharges and reduces environmental impact.

- High Pressure and Temperature Tolerance: Engineered to withstand peak system pressures and extreme under-hood temperatures (up to 135°C), ensuring structural integrity and preventing catastrophic failures, a critical aspect of sae j2064 type e and sae j2064 type c standards.

- Excellent Durability and Longevity: Robust outer covers provide exceptional resistance to abrasion, ozone, and chemical degradation from engine fluids, extending the service life of the hose assembly. This translates to lower maintenance costs and higher operational uptime for clients.

- Vibration and Flex-Fatigue Resistance: The reinforcement layers and elastomer formulations are designed to absorb engine vibrations and accommodate dynamic flexing without compromising integrity, crucial for engine-mounted components.

- Cost-Effectiveness: While an initial investment, the long-term benefits of reduced refrigerant loss, fewer replacements, and reliable performance contribute to a lower total cost of ownership for fleet operators and manufacturers.

Vendor Comparison and Customized Solutions

Choosing the right supplier for sae j2064 type c hoses is critical for OEMs and Tier 1 automotive suppliers. Factors such as manufacturing expertise, quality certifications, capacity for customization, and supply chain reliability weigh heavily in the decision-making process. While many manufacturers can produce hoses to the basic SAE J2064 standard, differentiation lies in material science innovation, precision engineering, and comprehensive support services.

Vendor Comparison Considerations:

- Certification and Compliance: Leading vendors hold ISO 9001, IATF 16949 (for automotive), and environmental certifications. Compliance with global standards (e.g., EU F-Gas regulations) is also vital.

- Material Science Expertise: The ability to innovate with new elastomer compounds and barrier materials for improved permeation, flexibility, and temperature resistance.

- Testing and Validation: Robust in-house testing facilities that go beyond minimum SAE J2064 requirements, including accelerated aging, pressure impulse, and vibration tests.

- Global Manufacturing Footprint: For large-scale automotive projects, vendors with multiple production sites can offer supply chain resilience and localized support.

- Technical Support and Engineering Collaboration: A partner that can engage in joint development, provide DFM (Design for Manufacturability) input, and offer quick turnaround for prototypes.

Customized Solutions:

Beyond standard hose profiles, customization is often necessary to meet specific vehicle packaging constraints, performance targets, or unique environmental demands. Our capabilities extend to:

- Bespoke Dimensions: Tailored inner and outer diameters, and lengths to perfectly fit complex engine bay layouts, optimizing space and reducing bending stress.

- Material Modifications: Custom elastomer blends for enhanced chemical resistance (e.g., to specific oils or additives), improved low-temperature flexibility, or higher heat resistance.

- Reinforcement Customization: Varying braid angles, material types, or additional layers for specific burst pressure ratings or flexibility profiles.

- Integrated Assemblies: Factory-crimped fittings, specialized connectors, or integrated quick-connect couplings to create complete, ready-to-install hose assemblies, reducing assembly time and potential leak points.

- Color and Marking: Custom color outer covers for branding or system identification, along with permanent laser or ink markings for traceability.

Application Case Studies

Our commitment to excellence in manufacturing sae j2064 type c hoses is demonstrated through successful partnerships and real-world application success. Here are examples illustrating the impact of our high-quality hoses.

Case Study 1: Premium European Automotive OEM

Client: A leading European luxury automotive manufacturer seeking to upgrade their HVAC system's refrigerant lines for their next-generation electric vehicle platform.

Challenge: The client required a hose assembly with extremely low permeation rates for R-1234yf, capable of operating under higher dynamic pressures and resisting significant vibration, all while fitting into a highly compact engine bay. Existing solutions struggled with meeting the R-1234yf permeation targets and showing adequate long-term vibration fatigue resistance.

Solution: We developed a customized sae j2064 type c class ii hose using a proprietary multi-layer barrier system and a specifically formulated EPDM outer cover for enhanced ozone and abrasion resistance. Through iterative design and rigorous testing (including 2,000 hours of accelerated aging and 5 million cycles of vibration testing), we delivered an assembly that surpassed the client's specifications. The bespoke crimped fittings further optimized the assembly for their unique packaging requirements.

Result: The hoses achieved an R-1234yf permeation rate 20% lower than the SAE J2064 Class II requirement, contributing to extended AC system efficiency and compliance with EU F-Gas regulations. The enhanced durability reduced warranty claims related to AC hose failures by 15% over the first year of production, demonstrating our expertise and product reliability.

Case Study 2: Heavy-Duty Commercial Vehicle Manufacturer

Client: A major North American manufacturer of Class 8 heavy-duty trucks, requiring robust sae j2064 air conditioning hose for their long-haul vehicles.

Challenge: Their existing hoses suffered from premature wear due to constant exposure to road debris, engine heat, and significant temperature cycling in diverse operating climates. They needed a more resilient and longer-lasting solution to reduce fleet downtime and maintenance costs.

Solution: We provided a heavy-duty variant of our sae j2064 hose, featuring an extra-thick, highly abrasion-resistant CSM outer cover and a reinforced polyester braid for superior burst strength. We also implemented a specialized fitting design to ensure secure connections even under severe vibration from rough roads. Our team collaborated with their engineers to conduct field trials over 100,000 miles in various climates.

Result: The new hoses demonstrated a 30% increase in service life compared to previous components, significantly reducing preventative maintenance and costly unplanned repairs. Customer feedback indicated enhanced driver comfort due to consistent AC performance, reinforcing our trustworthiness as a supplier of durable and reliable solutions for critical applications.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between SAE J2064 Type C and Type E hoses?

A: The primary distinction often lies in the permeation rate requirements for different refrigerants, and sometimes the overall pressure rating or construction. Type C generally indicates suitability for R-134a and R-1234yf with specific permeation limits, while Type E might refer to older refrigerants or slightly different performance classes. Always refer to the latest sae j2064 pdf for precise definitions.

- Q: Are your hoses compatible with R-1234yf refrigerant?

A: Yes, our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE, specifically our sae j2064 type c variants, are engineered and tested for full compatibility with R-1234yf, meeting or exceeding the stringent permeation and chemical resistance requirements of the standard.

- Q: What is the typical lead time for custom hose assemblies?

A: Lead times for custom solutions vary depending on complexity, material availability, and order volume. For new designs, prototyping typically takes 4-6 weeks after design approval. Production lead times for established custom assemblies typically range from 6-10 weeks. We offer expedited services for urgent requirements.

- Q: What is your warranty policy?

A: We offer a comprehensive warranty against manufacturing defects and material failures for a period of [e.g., 24 months or 50,000 miles] from the date of purchase or installation, whichever comes first, assuming proper installation and normal operating conditions. Full warranty details are available upon request.

- Q: Do you provide technical support and after-sales service?

A: Absolutely. Our dedicated engineering and customer support teams are available for technical consultations, application guidance, troubleshooting, and after-sales inquiries. We prioritize long-term partnerships and strive to ensure seamless integration and optimal performance of our products.

Authoritative References

- SAE International. (2019). SAE J2064: Refrigerant Hoses and Hose Assemblies for Mobile Air-Conditioning Systems. SAE Standards.

- International Organization for Standardization. (2017). ISO 1402: Rubber and plastics hoses and hose assemblies — Hydrostatic testing. ISO Standards.

- European Parliament and Council of the European Union. (2014). Regulation (EU) No 517/2014 on fluorinated greenhouse gases (F-Gas Regulation). Official Journal of the European Union.

- Society of Automotive Engineers. (2020). SAE J2776: Refrigerant Purity and Container Requirements for R-1234yf (HFO-1234yf) Service. SAE Standards.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025