Reliable SAE J2064 Type C Hose for HVAC AC Systems

Introduction to sae j2064 type c Air Conditioning Hoses

In the intricate landscape of modern thermal management systems, particularly within automotive and industrial air conditioning, the integrity and performance of every component are paramount. Central to the efficient and reliable operation of these systems are the refrigerant hoses. Among the myriad specifications, sae j2064 type c stands as a critical benchmark for high-performance air conditioning hose assemblies, engineered to meet the demanding requirements of contemporary refrigerants and operating conditions. This standard specifies the design, construction, and testing protocols for hoses intended for use with refrigerants such as R-134a and R-1234yf, ensuring minimal permeation, exceptional durability, and long-term service life.

The evolution of refrigerants, driven by environmental regulations and efficiency mandates, has necessitated a parallel advancement in hose technology. sae j2064 type c represents a leap forward, utilizing advanced multi-layer constructions and barrier materials to drastically reduce refrigerant permeation, thereby enhancing system efficiency and reducing environmental impact. This article delves into the technical intricacies, application advantages, and market relevance of this essential component, providing B2B decision-makers and technical engineers with a comprehensive understanding.

Industry Trends and Regulatory Landscape

The global automotive and industrial HVAC&R sectors are undergoing significant transformation, primarily driven by stringent environmental regulations and the push for greater energy efficiency. The transition from R-134a to lower Global Warming Potential (GWP) refrigerants like R-1234yf in mobile air conditioning (MAC) systems is a prime example. This shift directly impacts component design, requiring hoses that can reliably contain these new refrigerants which often have different permeation characteristics and material compatibilities. The sae j2064 standard, particularly its Type C classification, has evolved to address these challenges head-on.

Beyond refrigerant shifts, there's an increasing demand for enhanced durability and performance in extreme operating conditions. Modern vehicles and industrial machinery operate in diverse climates, from arctic cold to desert heat, necessitating hoses that maintain their integrity under wide temperature fluctuations, high pressures, and constant vibration. Manufacturers are also prioritizing weight reduction and assembly efficiency, driving innovation in hose materials and design. The focus on reducing noise, vibration, and harshness (NVH) also influences hose design, with solutions incorporating vibration-dampening properties becoming more prevalent.

Furthermore, the digitalization of manufacturing and increased supply chain complexity are pushing for greater transparency and traceability in component sourcing. Compliance with international standards such as ISO/TS 16949 (now IATF 16949) for automotive quality management systems, alongside specific material and safety certifications, is non-negotiable. The reliability of sae j2064 type c hoses is therefore not just a technical requirement but a strategic business imperative, contributing directly to product quality, regulatory compliance, and brand reputation.

Technical Specifications of sae j2064 type c

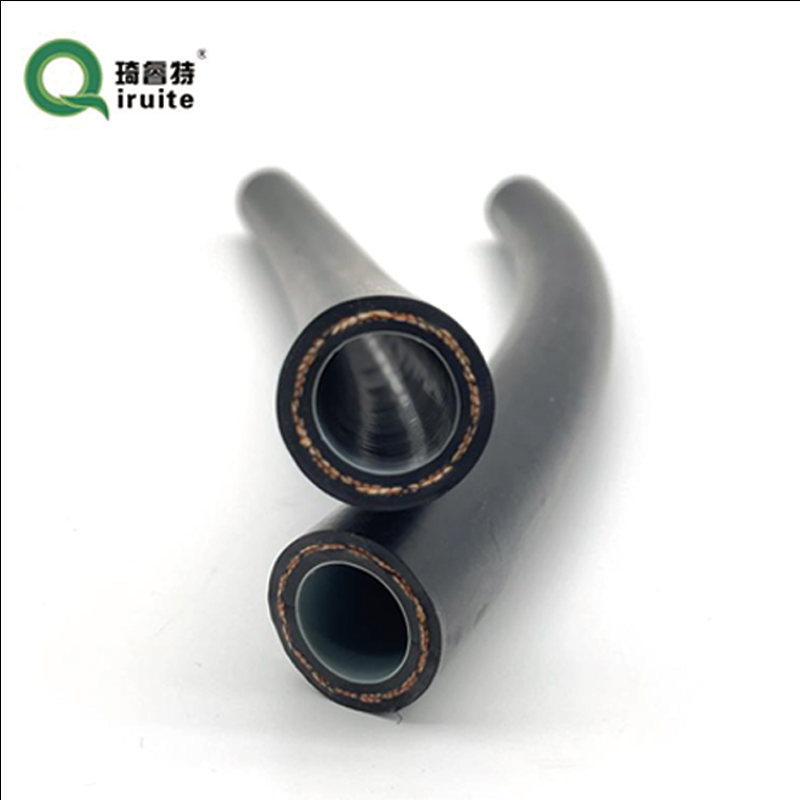

The sae j2064 type c specification outlines the critical performance characteristics for refrigerant hose assemblies. These hoses are typically multi-layered, engineered for maximum resistance to refrigerant permeation, chemical compatibility with various refrigerants and compressor oils, and superior mechanical integrity under varying pressures and temperatures. The "Type C" designation specifically refers to a barrier-type hose, designed for the lowest permeation rates, typically featuring a nylon or similar polymer barrier layer.

Key Structural Elements:

- Inner Liner: Often made of modified chloroprene rubber (CR), butyl rubber (IIR), or EPDM, selected for its excellent chemical resistance to refrigerants and oils.

- Permeation Barrier: A crucial layer, typically polyamide (nylon), EVOH, or a similar high-density polymer, designed to significantly reduce refrigerant diffusion through the hose wall. This is a defining characteristic of sae j2064 type c hoses.

- Reinforcement: One or more layers of high-strength synthetic fiber braid (e.g., polyester, aramid) embedded in rubber, providing burst strength and resistance to mechanical stresses.

- Outer Cover: Typically EPDM (ethylene propylene diene monomer) or a similar weather-resistant rubber, offering protection against ozone, UV radiation, abrasion, and automotive fluids.

Performance Parameters (Example Data for sae j2064 type c):

| Parameter | Typical Value for sae j2064 type c | Unit |

|---|---|---|

| Refrigerant Permeation (R-134a) | < 3.0 | kg/m²-year |

| Refrigerant Permeation (R-1234yf) | < 5.0 | kg/m²-year |

| Working Pressure (Max) | 35 - 50 | Bar (500 - 725 PSI) |

| Burst Pressure (Min) | 175 - 250 | Bar (2500 - 3625 PSI) |

| Temperature Range | -40 to +135 | °C |

| Minimum Bend Radius | 50 - 100 | mm (depending on ID) |

| Ozone Resistance | Excellent | (ASTM D1149) |

Note: Specific values may vary slightly between manufacturers and hose IDs, but adhere to the minimums set by the sae j2064 standard.

Manufacturing Process Flow for sae j2064 type c Hoses

The production of high-performance sae j2064 type c hoses is a sophisticated multi-stage process, demanding precision engineering and rigorous quality control at every step. This ensures that the final product meets the exacting standards for durability, permeation resistance, and overall reliability. The process typically combines advanced material science with precision manufacturing techniques.

Process Steps:

- Material Selection & Preparation: This initial phase is critical. High-grade synthetic rubbers such as EPDM, butyl rubber (IIR), or modified CR are selected for the inner tube and outer cover due to their chemical resistance and weatherability. For the crucial permeation barrier, specialized polymers like nylon (polyamide) or EVOH are chosen. Reinforcement materials typically involve high-tensile synthetic fibers like polyester or aramid. All raw materials undergo stringent quality checks to meet ISO and internal specifications.

- Inner Tube Extrusion: The chosen inner liner material is continuously extruded through a die to form the seamless inner tube of the hose. Precision control of temperature, pressure, and die dimensions is paramount to ensure uniform wall thickness and a smooth inner surface, critical for minimizing flow resistance and maximizing service life.

- Barrier Layer Extrusion: Directly over the inner tube, the high-performance permeation barrier material (e.g., nylon) is co-extruded or applied in a separate, highly controlled extrusion process. This layer is exceptionally thin but possesses dense molecular structures that significantly impede the migration of refrigerant molecules, meeting the low permeation requirements of sae j2064 type c.

- Reinforcement Braiding/Wrapping: One or more layers of high-strength textile braids are applied over the barrier layer. This reinforcement provides the necessary burst strength and resistance to vacuum collapse. Advanced braiding machines ensure consistent tension and angle, which are vital for uniform pressure distribution and flexibility.

- Outer Cover Extrusion: The protective outer cover, typically EPDM, is then extruded over the reinforcement layer. This layer provides resistance to environmental factors such as ozone, UV radiation, abrasion, and chemicals, protecting the internal structure and extending the hose's outdoor service life.

- Vulcanization/Curing: The raw hose assembly is then subjected to a controlled heating process (vulcanization or curing). This chemically cross-links the rubber compounds, transforming them into a durable, elastic, and stable material. This step sets the final mechanical properties of the hose, including its flexibility, pressure resistance, and temperature range.

- Cutting and Assembly: After curing, the hose is cut to precise lengths. Specialized crimping equipment is used to securely attach fittings, ensuring leak-proof connections. This assembly process requires precision to prevent damage to the hose layers and ensure the integrity of the connection under operational pressures.

-

Testing and Quality Assurance: Every batch undergoes rigorous testing to comply with sae j2064 and other relevant standards (e.g., ISO 1307 for dimensions, ANSI for specific applications). This includes:

- Permeation Testing: Critical for AC hoses, using specific refrigerants (R-134a, R-1234yf).

- Burst Pressure Testing: To ensure minimum burst strength.

- Impulse Testing: Simulating pressure pulsations in the system.

- Cold Flexibility and Heat Aging: To verify performance across the temperature spectrum.

- Ozone Resistance and Oil Resistance: For environmental and chemical compatibility.

- Dimensional Checks: Inner diameter, outer diameter, length tolerances.

- Packaging and Dispatch: Once all tests are passed, the hoses are meticulously cleaned, packaged, and prepared for dispatch to various target industries, including automotive OEM, heavy equipment, industrial HVAC, and specialized refrigeration applications.

Emphasis on quality control and adherence to testing standards (e.g., ISO 9001 certified manufacturing facilities, compliance with SAE J2064, ISO 1307) ensures a product with an extended service life and reliable performance in demanding environments. This meticulous process directly contributes to energy saving due to minimized refrigerant loss and superior corrosion resistance provided by the advanced material choices, making sae j2064 type c a preferred choice in critical applications.

Application Scenarios and Technical Advantages

The robust design and high-performance characteristics of sae j2064 type c hoses make them indispensable across a wide array of demanding applications where refrigerant containment and system efficiency are paramount. These hoses are engineered to excel in environments requiring resistance to extreme temperatures, high pressures, and corrosive elements.

Key Application Scenarios:

- Automotive Air Conditioning Systems: From passenger vehicles to heavy-duty trucks and buses, sae j2064 type c hoses are the standard for conveying refrigerants (R-134a, R-1234yf) between compressor, condenser, evaporator, and receiver-drier units. Their low permeation rate is crucial for maintaining optimal system charge and extending service intervals, directly contributing to energy saving and reduced maintenance costs.

- Off-Highway and Agricultural Equipment: Construction vehicles, tractors, excavators, and mining equipment operate in harsh conditions, exposed to dust, debris, vibration, and extreme temperatures. The superior abrasion and ozone resistance of sae j2064 hose ensures reliable AC performance, enhancing operator comfort and equipment longevity.

- Industrial HVAC and Refrigeration: Large-scale industrial cooling systems, process chillers, and specialized refrigeration units benefit from the high-pressure capabilities and long-term durability of these hoses. Industries like petrochemical, food processing, and data centers rely on consistent cooling, where hose integrity is critical to prevent costly downtime and product spoilage.

- Rail and Marine HVAC Systems: These applications require components that can withstand constant vibration, fluctuating temperatures, and the corrosive effects of salt spray or humid environments. The robust construction and material selection of sae j2064 type c class ii hoses provide the necessary reliability and resistance.

Technical Advantages:

- Superior Permeation Resistance: The defining advantage of sae j2064 type c is its advanced barrier layer, which dramatically reduces refrigerant loss compared to older hose types. This translates into longer system charge retention, fewer recharges, lower operational costs, and a reduced environmental footprint in line with F-gas regulations.

- Extended Service Life: Constructed from highly durable synthetic rubbers and reinforced with strong textile braids, these hoses offer exceptional resistance to heat aging, ozone degradation, and chemical attack from refrigerants and lubricants. This ensures a prolonged operational life even in harsh conditions, minimizing component replacement frequencies.

- High Pressure and Temperature Tolerance: Engineered to withstand peak system pressures and extreme temperature fluctuations (-40°C to +135°C), sae j2064 hose maintains its mechanical integrity and sealing properties under demanding operational cycles.

- Corrosion Resistance: The outer cover materials are specifically chosen to resist degradation from road salts, oils, greases, and industrial chemicals, ensuring the hose remains robust and functional throughout its expected lifespan, particularly crucial in automotive under-hood environments and industrial settings.

- Vibration Dampening: The flexible rubber construction inherently absorbs and dampens vibrations from the compressor and engine, reducing NVH levels within the vehicle or machinery and preventing stress on connected components.

- Compliance with Latest Standards: Adherence to the latest revisions of sae j2064 signifies compliance with global industry best practices and regulatory requirements, providing peace of mind regarding performance and safety.

Vendor Comparison and Customized Solutions

Selecting the right supplier for sae j2064 type c hoses is critical for maintaining system performance, ensuring longevity, and optimizing cost-efficiency. While the standard sets minimum requirements, variations in manufacturing processes, material sourcing, and additional quality controls can differentiate vendors. B2B purchasers should evaluate suppliers not just on price, but on a holistic view of quality, technical support, and customization capabilities.

Key Factors for Vendor Comparison:

- Certifications: Verify ISO 9001, IATF 16949 (for automotive), and specific product certifications like sae j2064 pdf compliance reports.

- Material Traceability: Assurance of raw material quality and origin.

- R&D Capabilities: A vendor's ability to innovate and adapt to new refrigerants or extreme conditions.

- Testing Protocols: Beyond standard compliance, look for internal testing regimes that exceed minimum requirements.

- Customer Support: Technical assistance, responsiveness, and problem-solving capabilities.

- Lead Times and Supply Chain Reliability: Critical for consistent production schedules.

Comparative Analysis of sae j2064 type c Hoses (Illustrative):

| Feature/Parameter | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Cost-Optimized) |

|---|---|---|---|

| Permeation Rate (R-134a, kg/m²-year) | < 2.5 | < 3.0 | < 3.5 |

| Max Working Pressure (Bar) | 50 | 40 | 35 |

| Temperature Range (°C) | -45 to +140 | -40 to +135 | -35 to +130 |

| Burst Pressure Safety Factor | 5:1 | 4:1 | 4:1 (SAE Min) |

| Outer Cover Material | Advanced EPDM Blend | Standard EPDM | Basic EPDM |

| Certifications | IATF 16949, ISO 9001, J2064 Type C Class II | ISO 9001, J2064 Type C | J2064 Type C |

This table is illustrative. Actual performance may vary. Always consult specific product datasheets.

Customized Solutions:

For unique applications or complex system integrations, off-the-shelf sae j2064 hose assemblies may not always suffice. Leading manufacturers offer extensive customization options, collaborating closely with clients to develop tailored solutions. This can include:

- Specific Lengths and Configurations: Hoses can be cut to precise lengths and assembled with various end fittings (e.g., crimped, quick-connect) to meet exact system layout requirements.

- Optimized Materials: While adhering to sae j2064 type c, inner tube or outer cover compounds can be optimized for enhanced chemical resistance (e.g., specific oils, fuels), extreme temperature performance, or superior abrasion resistance.

- Color Coding and Branding: Custom colors for identification or branding purposes, along with private labeling, are often available.

- Integrated Components: Some manufacturers can integrate sensors, protective sleeves, or routing clips directly into the hose assembly, simplifying installation and improving overall system reliability.

- Specialized Testing: Beyond standard requirements, custom testing protocols can be developed to simulate unique operational stress factors, ensuring performance in highly specialized applications.

Application Case Studies

Real-world applications demonstrate the tangible benefits of utilizing sae j2064 type c hoses. These case studies highlight how superior engineering and adherence to strict standards translate into improved operational efficiency, reduced maintenance, and enhanced system reliability for our clients.

Case Study 1: Heavy-Duty Truck OEM

Challenge: A major heavy-duty truck manufacturer faced persistent issues with refrigerant loss and premature hose degradation in their AC systems, especially in trucks operating in extreme climates (e.g., deserts, arctic regions). Existing hoses, while meeting basic standards, exhibited higher-than-desired permeation rates and susceptibility to ozone cracking, leading to frequent system recharges and warranty claims. This impacted customer satisfaction and operational costs.

Solution: Collaborating with a specialized hose manufacturer, the OEM transitioned to a custom-designed sae j2064 type c hose assembly. This solution featured an optimized multi-layer construction with an enhanced nylon barrier for ultra-low permeation and a robust EPDM outer cover with superior ozone and abrasion resistance. The assemblies were rigorously tested for impulse endurance, extreme temperature cycling, and long-term permeation under simulated field conditions.

Results: After implementing the new j2064 hose, the OEM reported a 40% reduction in refrigerant top-ups over a 5-year period and a 60% decrease in hose-related warranty claims. The enhanced durability significantly extended the service life of the AC system components, improving overall vehicle reliability and reducing total cost of ownership for their customers. Driver comfort in diverse operating environments also notably improved.

Case Study 2: Industrial Refrigeration for Food Processing

Challenge: A large-scale food processing plant required an upgrade to its primary refrigeration system, which utilized R-134a. The existing hose network, comprising older specifications, exhibited high permeation rates, leading to substantial energy losses and compliance concerns regarding F-gas regulations. The constant humidity and sanitation processes also caused premature degradation of the hose covers.

Solution: The plant adopted sae j2064 type c hoses across its refrigeration lines. The supplier provided hose assemblies specifically designed for continuous operation at elevated pressures and with enhanced resistance to moisture and cleaning agents. The superior barrier technology ensured minimal refrigerant leakage, aligning with environmental mandates and improving operational efficiency.

Results: Post-implementation, the plant observed a 15% reduction in annual energy consumption attributable to better refrigerant containment. Refrigerant top-up frequency was reduced by over 50%, and the new hoses showed no signs of degradation after 3 years, significantly outperforming the previous system's components. This resulted in substantial cost savings and improved environmental performance.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between sae j2064 type c and other SAE J2064 types?

- A1: The primary difference lies in the permeation barrier and thus, the permeation rate. sae j2064 type c specifies a barrier-type hose designed for very low refrigerant permeation, making it suitable for modern, environmentally conscious AC systems, especially those using R-1234yf or requiring superior R-134a containment. Other types (like Type A or B, if still in use) may have higher permeation rates or different construction for less demanding applications or older refrigerants.

- Q2: Can sae j2064 type c hoses be used with R-1234yf refrigerant?

- A2: Yes, sae j2064 type c hoses are specifically engineered and tested to be compatible with R-1234yf refrigerant, alongside R-134a. Their multi-layer construction with a high-performance barrier layer is crucial for effectively containing R-1234yf, which has a higher permeation tendency than R-134a, ensuring compliance with environmental regulations and maintaining system efficiency.

- Q3: What are the typical lead times for custom sae j2064 type c hose orders?

- A3: Lead times for custom sae j2064 type c hose orders can vary based on the complexity of the design, required volume, and current production schedules. Standard products typically range from 2-4 weeks, while highly customized solutions or large-volume orders may require 6-10 weeks. We recommend contacting our sales team directly with your specific requirements for a precise lead time estimate. Rush orders can often be accommodated with advanced planning.

- Q4: What warranty is provided for your sae j2064 type c hoses?

- A4: We stand behind the quality and performance of our sae j2064 type c hoses with a comprehensive warranty. Our standard warranty covers defects in material and workmanship for a period of 12 to 24 months from the date of purchase, depending on the product series and application. Specific warranty details are provided with each order and can be discussed with our sales representatives to ensure they meet your project requirements.

Lead Time, Fulfillment, and Customer Support

At HoseQRT, we understand that reliable supply chain management is as crucial as product performance. We are committed to providing efficient order fulfillment and robust customer support to ensure seamless integration of our sae j2064 type c hoses into your operations.

Lead Time and Fulfillment:

- Standard Orders: For standard configurations of our E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE, typical lead times range from 2 to 4 weeks, depending on inventory levels and order volume.

- Customized Solutions: Custom sae j2064 type c assemblies, requiring specific lengths, fittings, or material modifications, generally have a lead time of 6 to 10 weeks, encompassing design, prototyping, testing, and production.

- Expedited Services: We offer expedited manufacturing and shipping options for urgent requirements. Please contact our sales team to discuss specific needs and feasibility.

- Logistics: We partner with trusted global logistics providers to ensure timely and secure delivery, offering various shipping options including air freight, sea freight, and express courier services.

Warranty Commitments:

Our commitment to quality is underscored by our comprehensive warranty policy. All our sae j2064 type c products are backed by a minimum 12-month warranty against manufacturing defects in materials and workmanship. This commitment reflects our confidence in the rigorous quality control and manufacturing processes that ensure every hose meets or exceeds industry standards. Extended warranty options are available for specific project requirements or strategic partnerships.

Dedicated Customer Support:

We provide comprehensive customer support, from initial inquiry to post-installation assistance. Our team of experienced technical engineers and sales professionals is available to:

- Provide detailed product specifications and application guidance.

- Assist with custom design and engineering consultations.

- Offer technical troubleshooting and problem resolution.

- Support with order tracking and logistics coordination.

- Process warranty claims efficiently and fairly.

Our dedication to client success extends beyond product delivery, ensuring that you receive unparalleled service and support throughout the lifecycle of our sae j2064 air conditioning hose solutions.

Conclusion

The selection of high-quality refrigerant hose assemblies is a non-negotiable aspect of modern thermal management systems. sae j2064 type c stands as the pinnacle of performance and reliability in this domain, offering a robust solution that addresses the evolving demands of environmental regulations, refrigerant technologies, and extreme operating conditions. Its multi-layer construction, superior permeation resistance, and exceptional durability contribute significantly to system efficiency, reduced operational costs, and extended service life across automotive, off-highway, and industrial applications.

By prioritizing hoses compliant with sae j2064, businesses ensure not only optimal system performance and regulatory adherence but also bolster their reputation for quality and sustainability. The investment in such advanced components is an investment in long-term reliability and operational excellence.

References

- SAE International. (2020). J2064: R134a and R1234yf Refrigerant Hoses and Assemblies for Mobile Air-Conditioning Systems. Warrendale, PA: SAE International.

- ISO. (2014). ISO 1307: Rubber and plastics hoses and hose assemblies — Textile-reinforced hydraulic and pneumatic hoses — Dimensions and burst pressures. Geneva, Switzerland: International Organization for Standardization.

- ASHRAE. (2021). ASHRAE Handbook—HVAC Systems and Equipment. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- European Commission. (2014). Regulation (EU) No 517/2014 on fluorinated greenhouse gases (F-gas Regulation). Official Journal of the European Union.

- Environmental Protection Agency (EPA). (2018). Significant New Alternatives Policy (SNAP) Program. Washington D.C.: United States Environmental Protection Agency.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025