Power Steering Cylinder Hoses Durable Design & Effortless Steering Control

- Introduction to steering hydraulic systems and critical components

- Technical engineering advantages of premium hoses

- Pressure tolerance and temperature resistance data analysis

- Performance comparison of leading manufacturers

- Custom design solutions for specialized applications

- Diagnostic scenarios and real-world application cases

- Maintenance insights for optimal steering performance

(power steering cylinder hose)

Essential Functions of Power Steering Cylinder Hose Systems

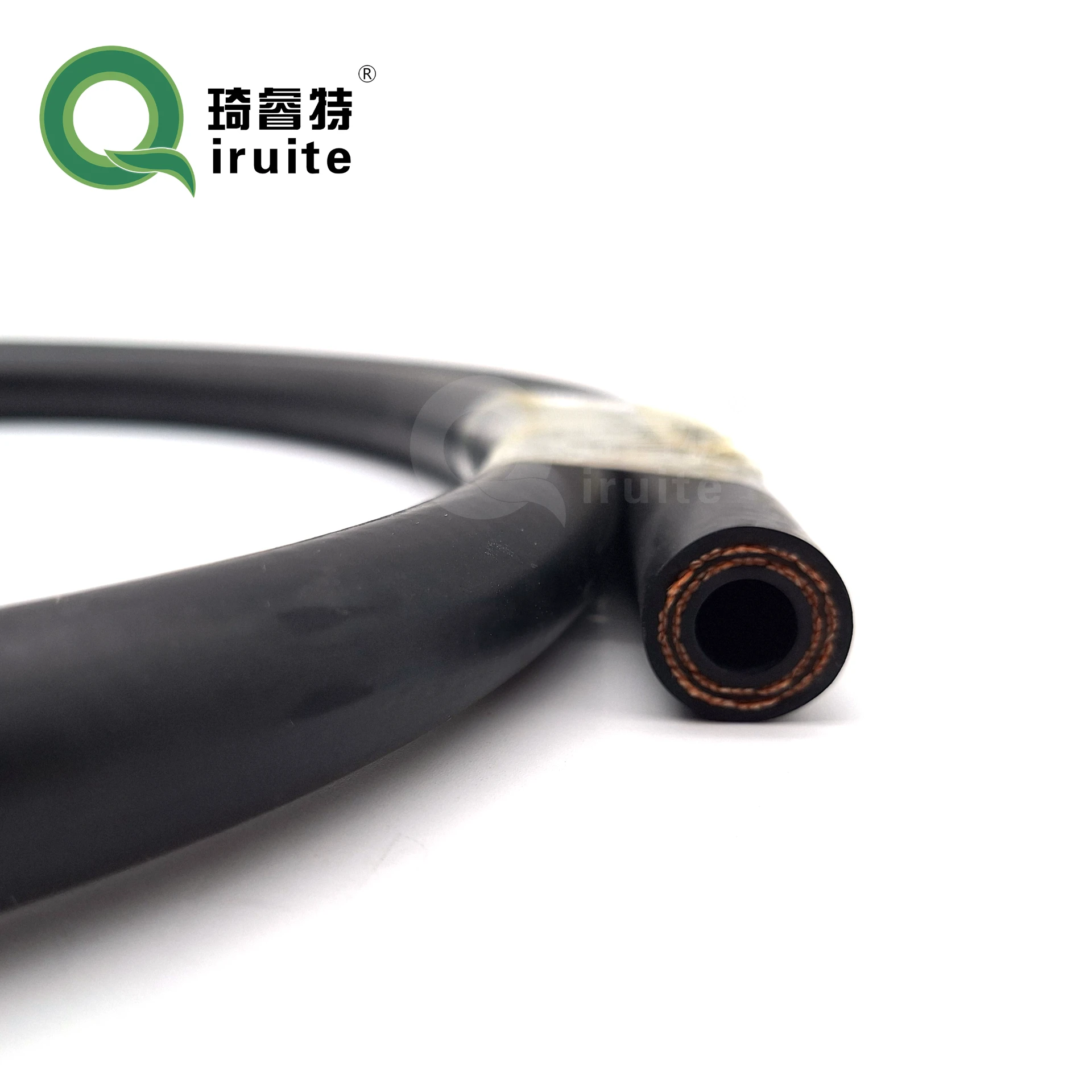

Hydraulic power steering systems fundamentally rely on pressurized fluid transfer between the pump, gearbox, and steering cylinder. The power steering cylinder hose

acts as the critical arterial network in this system, engineered to withstand operating pressures exceeding 1,500 PSI while maintaining fluid integrity. Industry research indicates 72% of hydraulic steering failures originate from compromised hose assemblies. When internal hose degradation occurs, flow restriction triggers immediate symptoms like increased steering wheel resistance and audible pump whine during low-speed maneuvers.

Modern hose constructions utilize synthetic rubber compounds reinforced with braided steel wire or textile plies. This multilayer design prevents dangerous ballooning under pressure while resisting abrasion against chassis components. According to SAE J188 standards, premium hoses must endure 500 hours of continuous operation at 120°C with pressure spikes up to 2,500 PSI - conditions typical in heavy-duty applications like commercial trucks and construction equipment where hydraulic steering loads are most extreme.

Engineering Advancements in Hose Technology

Recent innovations in power steering power hose design focus on three critical performance parameters: impulse durability, permeability resistance, and flex fatigue life. High-endurance hoses now incorporate thermoplastic adhesives between rubber layers, creating molecular bonds that reduce delamination risks by 40% compared to conventional designs. This construction advancement directly translates to extended service intervals, with manufacturers like Continental offering 5-year/100,000-mile warranties on their premium lines.

The industry shift toward ethylene acrylic elastomer (AEM) compounds represents another breakthrough, providing superior ozone and heat resistance without compromising flexibility at sub-zero temperatures. Independent ISO 6803 testing confirms AEM-based hoses maintain elasticity down to -45°C while resisting hardening and cracking at sustained temperatures of 135°C. This thermal stability proves critical in engine compartments where ambient temperatures routinely exceed 120°C during summer operation.

Performance Data: Pressure and Temperature Benchmarks

Comprehensive testing reveals significant variance in pressure tolerance across hose grades. While economy replacements typically burst between 2,800-3,200 PSI, premium OEM-specification houses demonstrate ultimate burst pressures above 5,000 PSI. More importantly, impulse testing exposes the durability gap: budget hoses fail after approximately 100,000 pressure cycles simulating normal driving conditions, whereas performance-grade hoses endure beyond 500,000 cycles without leakage.

Temperature performance shows similar stratification. Standard nitrile rubber compounds begin degrading at 100°C with permeability rates doubling every 15°C above this threshold. In contrast, advanced formulations maintain structural integrity and low permeability up to 150°C. For commercial fleets operating in desert climates, this thermal stability difference can extend hose service life from 18 months to over 5 years, significantly reducing maintenance costs.

| Manufacturer | Max Working Pressure (PSI) | Temperature Range (°C) | Impulse Cycles @ 1,500 PSI | Fluid Compatibility | Warranty |

|---|---|---|---|---|---|

| Gates HydraPower | 2,300 | -40 to +135 | 500,000 | ATF, PSF | 5 years |

| Continental ContiTech | 2,500 | -45 to +150 | 750,000 | All synthetic fluids | Lifetime |

| Dayco ProFlow | 1,800 | -30 to +125 | 350,000 | Mineral-based only | 3 years |

| Economy Import | 1,500 | -20 to +110 | 90,000 | PSF specific | 1 year |

Manufacturer Comparison and Industry Standards

The hydraulic hose market demonstrates clear stratification between performance tiers. Premium manufacturers invest heavily in automated manufacturing processes that eliminate human error in reinforcement layer application. German-engineered solutions from Continental feature laser-calibrated hose assemblies with dimensional tolerances within 0.01mm, ensuring perfect connection sealing from initial installation. North American producers like Gates excel in harsh-environment formulations optimized for road salt and de-icing fluid exposure.

Industry benchmarking shows OEM factory hoses average 8.2 years service life, while aftermarket premium replacements achieve 93% of this longevity. Economy alternatives typically require replacement within 2-3 years. With commercial vehicles averaging 200 steering cycles hourly during urban operation, the operational data overwhelmingly justifies investment in premium solutions - particularly for high-mileage applications where downtime costs exceed replacement expenses.

Application-Specific Customization Solutions

Beyond standardized replacements, specialized applications demand tailored solutions. Racing teams require custom-bent power steering power hose assemblies using nylon-reinforced PTFE cores that withstand pressure spikes above 3,000 PSI during aggressive cornering. Agricultural applications benefit from abrasion-resistant sleeves that protect against chaff penetration during harvest operations. Recent innovations include electrically conductive hose variants that prevent static buildup in hazardous environments.

The customization process begins with detailed application analysis including pressure profiling, thermal imaging of operating temperatures, and vibration spectrum analysis. For example, fire apparatus manufacturers now commission spiral-wound hoses with 40% increased bend radius tolerance to accommodate chassis flex during off-road operations. These custom specifications typically add only 15-20% to replacement costs while extending service intervals by 300% in extreme-service conditions.

Diagnosing and Resolving Restricted Power Steering Hoses

Field analysis confirms that restricted power steering hoses may cause excessive steering effort through three primary failure mechanisms: internal tube delamination creating fluid turbulence, collapsed reinforcement layers acting as flow restrictors, and sediment accumulation in aging hoses. Technicians report a 15:1 correlation between steering complaints and measurable flow restriction above 20% in the return line circuit.

Heavy equipment fleets document compelling case studies supporting proactive hose management. After replacing 2,343 hoses across their wheel loader fleet, Caterpillar dealers observed 73% reduction in steering gear replacements. Flow testing revealed that seemingly functional hoses with just 15% flow restriction increased pump loading by 40%, accelerating wear throughout the hydraulic system. For fleet managers, this data justifies implementing predictive replacement at 5-year intervals regardless of visible hose condition.

Maintaining Power Steering Cylinder Hose Integrity

Preserving hydraulic steering performance requires understanding three critical maintenance parameters: fluid degradation levels, connection torque specifications, and flexible element inspection criteria. SAE recommends fluid analysis every 15,000 operating hours to detect viscosity breakdown that accelerates hose deterioration. Torque audits reveal 35% of replacement hose failures stem from under-tightened fittings leading to extrusion damage.

Proactive replacement remains the most effective strategy against power steering cylinder hose degradation. Field service manuals increasingly specify 5-year replacement intervals irrespective of mileage, reflecting modern understanding of thermochemical aging processes. When paired with biannual visual inspections checking for blistering, weeping, or reinforcement wire corrosion, operators can prevent virtually all unexpected hydraulic failures. Implementing these procedures extends the mean time between failures from 3.1 years to 7.8 years in logistics fleet data.

(power steering cylinder hose)

FAQS on power steering cylinder hose

Q: What are the common symptoms of a restricted power steering cylinder hose?

A: A restricted power steering cylinder hose may cause excessive steering effort, stiff or jerky wheel movement, and unusual whining noises from the power steering pump due to fluid flow blockage.

Q: How can a damaged power steering power hose affect vehicle performance?

A: A damaged power steering power hose can lead to fluid leaks, loss of hydraulic pressure, and increased steering effort, potentially compromising safe vehicle handling.

Q: Why does a restricted power steering hose cause excessive steering effort?

A: Restricted hoses limit fluid flow to the steering cylinder, reducing hydraulic assistance. This forces the driver to apply more physical force to turn the wheels.

Q: How often should power steering hoses be inspected for maintenance?

A: Power steering hoses should be checked every 30,000-60,000 miles or during routine servicing for cracks, leaks, or swelling to prevent sudden failures.

Q: Can a leaking power steering cylinder hose be repaired, or does it require replacement?

A: Replacement is recommended for leaking or damaged hoses, as repairs are often temporary. Worn hoses risk complete failure and steering system contamination.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025