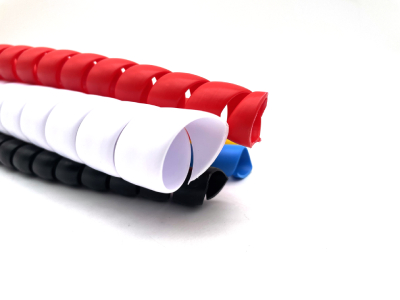

spiral wrap hose protector

The Benefits of Spiral Wrap Hose Protectors

In various industrial and commercial applications, hoses play a crucial role in the transportation of fluids and gases. However, exposure to harsh environments, wear and tear, and mechanical damage can significantly shorten the lifespan of hoses. To mitigate these risks, the use of spiral wrap hose protectors has gained popularity across many sectors. These protectors not only enhance the durability of hoses but also improve safety and efficiency. This article explores the key benefits of using spiral wrap hose protectors, and how they can contribute to the longevity and performance of hoses in various applications.

Understanding Spiral Wrap Hose Protectors

Spiral wrap hose protectors are helical coils made from durable materials such as polyethylene or PVC. Designed to be applied over hoses, these wraps provide a barrier against environmental factors that can lead to damage. Available in various sizes and colors, they are versatile enough to suit different types and dimensions of hoses used across industries such as construction, agriculture, and manufacturing.

Enhanced Protection Against Abrasion

One of the primary advantages of spiral wrap hose protectors is their ability to shield hoses from abrasion. Hoses that come into contact with rough surfaces are prone to wear, which can lead to leaks and ultimately failure. The spiral wrap acts as a cushion, preventing direct contact between the hose and external surfaces. This is particularly beneficial in environments with heavy machinery where hoses may be subject to constant movement and friction. By providing an extra layer of protection, these wraps can extend the life of hoses and reduce the need for frequent replacements.

Resistance to UV and Chemical Damage

spiral wrap hose protector

In addition to physical abrasion, hoses often face degradation from ultraviolet (UV) radiation and harsh chemicals. Many spiral wraps are designed to be UV resistant, which helps prevent the material’s breakdown when exposed to sunlight. This is especially important for hoses used outdoors, where prolonged sun exposure can cause plastic materials to become brittle and crack. Furthermore, certain spiral wraps provide additional chemical resistance, ensuring that hoses remain intact even when transporting aggressive fluids. This resistance is crucial in fields such as agriculture and chemical manufacturing, where exposure to corrosive substances is common.

Improved Safety

Safety is a paramount concern in any industrial setting. Damaged hoses can lead to leaks, spills, or bursts, creating hazardous situations for workers and equipment. By utilizing spiral wrap hose protectors, businesses can minimize the risk of hose damage and potential accidents. The added durability helps contain the transported fluids, reducing the likelihood of leaks that could pose safety risks. Moreover, the visibility offered by colored wraps can enhance safety measures by making hoses more recognizable, allowing workers to navigate environments with greater awareness.

Cost-Effectiveness and Efficiency

Investing in spiral wrap hose protectors can lead to significant long-term savings. While there may be an upfront cost, the increased lifespan of protected hoses translates to reduced replacement expenses. Additionally, avoiding unexpected downtime due to hose failures enhances operational efficiency, enabling businesses to maintain productivity without costly interruptions. Over time, the cost of implementing these protectors can be quickly recouped through reduced maintenance and replacement costs.

Conclusion

Spiral wrap hose protectors are valuable tools in extending the life of hoses and ensuring safe operations across various industries. By providing resistance against abrasion, UV rays, and chemicals, they effectively mitigate risks associated with hose wear and tear. The investment in these protectors not only enhances safety but also offers a cost-effective solution for maintaining efficient operations. As industries continue to prioritize safety and durability, incorporating spiral wrap hose protectors into regular maintenance practices becomes a prudent choice.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025