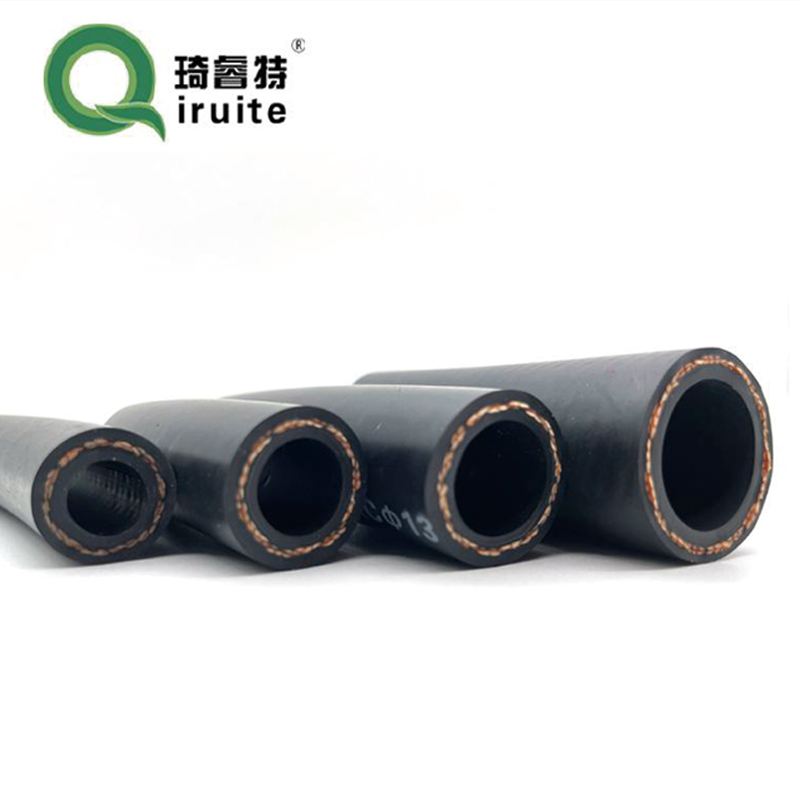

spiral wrap hose

Understanding Spiral Wrap Hose A Comprehensive Guide

In various industries, hoses play a crucial role in the efficient transport of fluids and gases. Among the diverse types available, spiral wrap hoses stand out due to their versatility, durability, and protective capabilities. This article will delve into what spiral wrap hoses are, their applications, advantages, and considerations when choosing the right one for your needs.

What is a Spiral Wrap Hose?

A spiral wrap hose is typically made of flexible tubing designed to encase and protect other hoses and cables. It is constructed in a spiral shape, which means it can expand and contract, accommodating movement and stress without compromising on its protective qualities. These wraps are primarily made from materials such as polyethylene, polyamide, or PVC, which enhance their durability and resistance to abrasion, impact, and UV radiation.

Applications of Spiral Wrap Hose

Spiral wrap hoses are widely utilized across various sectors, including agriculture, construction, automotive, and manufacturing. Here are some common applications

1. Agriculture Farmers use spiral wraps to protect irrigation hoses and cables from environmental factors such as sunlight and moisture, reducing wear and tear. 2. Automotive In automotive settings, spiral wrap hoses are employed to bundle and protect hydraulic lines and wiring from abrasions, allowing for smoother operation and longevity of vehicle systems.

3. Manufacturing Machinery in factories often requires protection for various hoses and cables, especially those that undergo frequent movement. Spiral wraps help prevent damage, minimizing downtime during operations.

4. Construction Sites Equipment on construction sites is exposed to harsh conditions. Spiral wraps provide essential protection to hydraulic lines and electrical cables, reducing the risk of costly repairs.

Advantages of Spiral Wrap Hose

The benefits of using spiral wrap hoses extend beyond just protection

. Here are a few significant advantages1. Durability Made from tough materials, spiral wrap hoses can resist abrasion, cuts, and impacts, ensuring the safety of the hoses and cables they protect.

spiral wrap hose

2. Flexibility The spiral design allows for a high degree of flexibility, accommodating movement without kinking or damaging the housed cables or hoses.

3. Reduced Downtime By protecting critical components from wear and tear, spiral wraps contribute to lower maintenance costs and increased operational efficiency.

4. Easy Installation Spiral wrap hoses are relatively simple to install. They can be cut to desired lengths and fitted without requiring specialized tools, making them convenient for various applications.

5. Cost-Effective Compared to the cost of potential repairs or replacements of damaged hoses and cables, investing in spiral wrap hoses can save significant money in the long term.

Considerations When Choosing Spiral Wrap Hose

While spiral wrap hoses offer various benefits, there are also considerations to keep in mind when selecting the right one for your application

1. Material Compatibility Ensure the material of the spiral wrap is compatible with the hoses or cables it will encase, taking into account factors like temperature resistance and chemical exposure.

2. Diameter Size Choose the appropriate diameter of the spiral wrap to ensure it fits snugly around the hose or cable, offering effective protection without being too loose or too tight.

3. Environmental Conditions Consider the operating environment. If the hoses will be exposed to extreme temperatures or chemicals, opt for materials that offer higher resistance.

4. Application Requirements Different applications may require specific attributes, such as added flexibility for quick movements or enhanced durability for rugged environments.

Conclusion

In summary, spiral wrap hoses are an invaluable asset in various industries, providing effective protection and enhancing the longevity of cables and hoses. Their durability, flexibility, and cost-effectiveness make them a wise investment for anyone relying on hoses in demanding applications. By considering material compatibility, size, and environmental conditions, you can choose the right spiral wrap hose that meets your specific needs and enhances operational efficiency. Investing in quality spiral wrap hoses not only protects your equipment but also contributes to a safer and more efficient working environment.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025