spiral hose wrap

The Benefits of Using Spiral Hose Wraps A Comprehensive Guide

In today's fast-paced industrial environment, where efficiency and organization are paramount, utilizing the right tools and materials can significantly enhance performance. One such tool that has been gaining popularity in various industries is the spiral hose wrap. This product, while seemingly simple, offers a plethora of benefits that make it indispensable for any workshop, garage, or industrial setting. In this article, we will explore what spiral hose wraps are, their advantages, and how to properly use them.

What is a Spiral Hose Wrap?

A spiral hose wrap is a protective sleeve designed to enclose hoses, cables, and wires. Typically made from durable materials like polyethylene, nylon, or even reinforced polypropylene, these wraps are constructed to withstand the rigors of industrial use while providing robust protection against abrasion, crushing, and environmental factors. The spiral design allows the wrap to conform closely to the shape of the wrapped items while offering a smooth exterior surface.

Advantages of Spiral Hose Wraps

1. Protection Against Damage One of the primary reasons for using spiral hose wraps is to protect hoses and cables from damage. In industrial settings, hoses can be subjected to harsh conditions, including exposure to chemicals, abrasives, and mechanical wear. The spiral wrap acts as a barrier, significantly prolonging the life of these components.

2. Organization and Tidiness A tangle of hoses and wires can create not only a messy workspace but also pose safety hazards. Spiral hose wraps help keep cables organized by bundling them together neatly. This organization not only improves aesthetics but also enhances safety by reducing the risk of tripping hazards in the workplace.

3. Easy Installation Spiral hose wraps are incredibly user-friendly. They can be installed quickly without the need for elaborate tools or equipment. Simply wrap the hose or cable with the spiral wrap, and it clings securely in place. This ease of use makes them an attractive option for both professionals and DIY enthusiasts.

4. Versatility Spiral hose wraps are versatile enough to be used in a multitude of applications. Whether you're managing hydraulic hoses, electrical wires, or even garden hoses, these wraps can accommodate a variety of sizes and types. This flexibility makes them a valuable tool across various industries, including automotive, manufacturing, and construction.

5. Heat Resistance Many spiral hose wraps are designed to withstand high temperatures, making them suitable for environments where heat is a factor. This is particularly beneficial in automotive applications or areas where machinery operates at elevated temperatures, as it helps to shield hoses from heat damage and potential failure.

spiral hose wrap

6. Chemical Resistance Depending on the material used, some spiral hose wraps offer excellent resistance to chemicals, oils, and solvents. This characteristic is essential in environments where hoses might come into contact with various substances that could degrade them over time.

How to Use Spiral Hose Wraps

Using spiral hose wraps is a straightforward process, but adhering to a few best practices can enhance their effectiveness

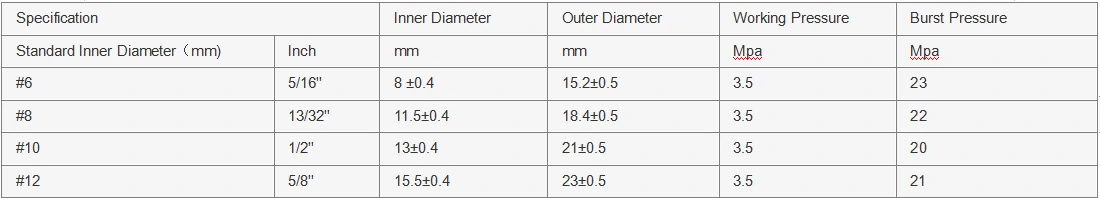

1. Select the Right Size Ensure that you choose a spiral wrap that fits the diameter of the hose or cable you wish to cover. Most wraps are available in a range of sizes to accommodate various applications.

2. Clean the Surface Before applying the wrap, clean the surface of the hose or cable to remove any dirt, oil, or debris. This step ensures that the wrap adheres properly and provides maximum protection.

3. Apply the Wrap Start at one end of the hose, gently spiraling the wrap around it. Overlap each turn slightly to ensure complete coverage. Continue wrapping until you reach the desired length.

4. Secure the Ends Depending on the application, you may want to secure the ends of the wrap with tape, zip ties, or clamps to ensure that it remains in place.

5. Inspect Regularly Regularly check the integrity of the spiral wrap, especially in high-use areas. Replace or repair any damaged sections as needed to ensure continued protection.

Conclusion

In conclusion, spiral hose wraps are a simple yet highly effective solution for protecting hoses and cables in various settings. Their ability to organize and secure, coupled with their durability and versatility, make them an essential component in maintaining an efficient and safe workspace. Whether you are a seasoned professional or a DIY hobbyist, investing in spiral hose wraps will undoubtedly pay off by increasing the longevity of your equipment and enhancing workplace safety.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025