Feb . 10, 2025 11:34

Back to list

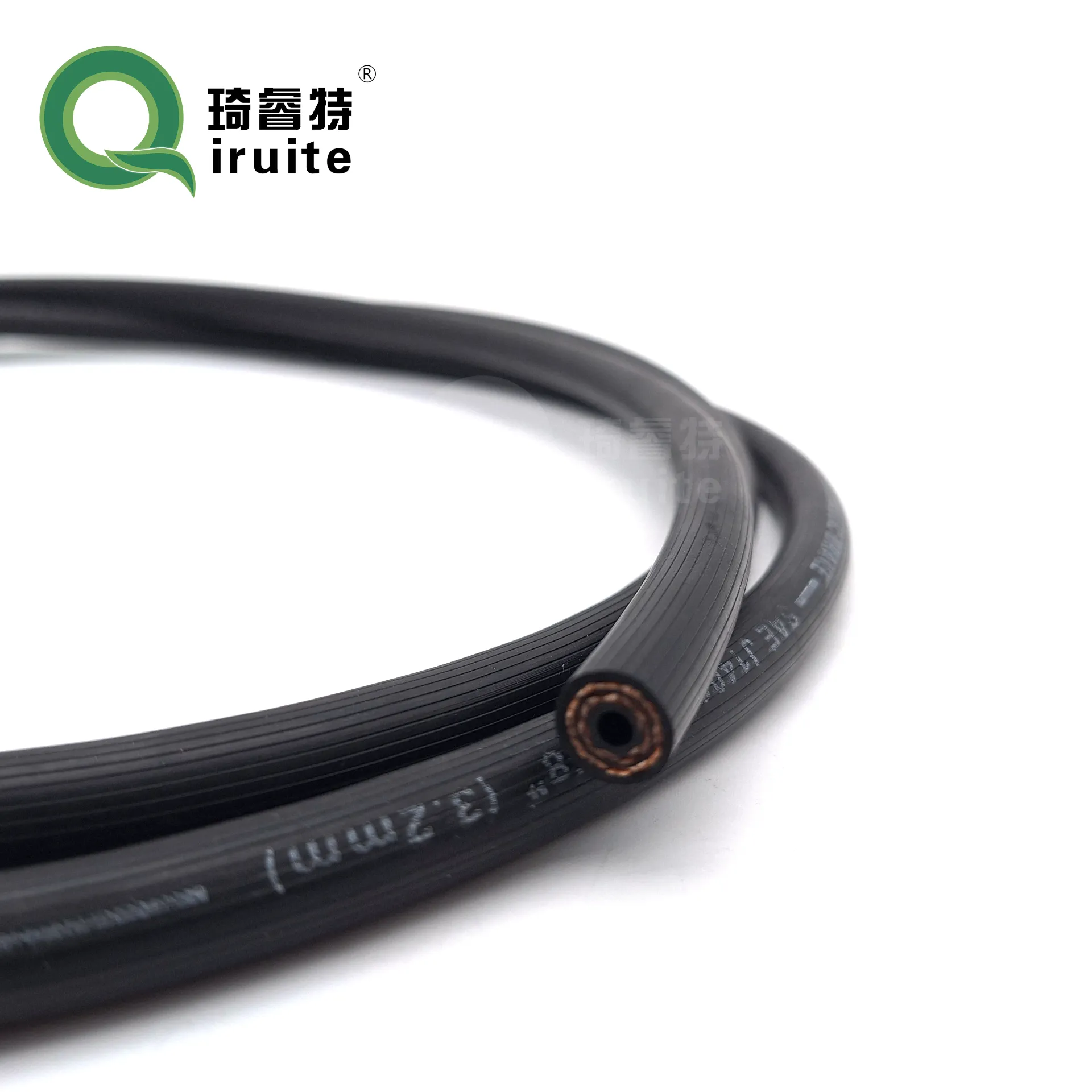

spiral guard

Slip on pipe couplings are indispensable components in numerous industries where efficient and robust pipe connections are essential. This article delves into their multifaceted applications, technological advancements, and the critical factors influencing their selection and usage, providing valuable insights for professionals seeking to optimize their pipe coupling solutions.

Authoritativeness is established through adherence to industry standards, which ensures that slip on pipe couplings meet stringent safety and performance criteria. Reputable manufacturers often adhere to standards such as the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM), which guarantee that the couplings conform to specific design, performance, and safety benchmarks. Ensuring compliance with such standards is crucial for maintaining the integrity of piping systems, especially in critical applications like those found in the oil and gas sector. The trustworthiness of slip on pipe couplings is further reinforced by their proven track record in various applications around the globe. With advancements in manufacturing techniques and materials, these couplings continue to evolve, offering enhanced performance and reliability. Companies investing in high-quality slip on pipe couplings benefit from reduced maintenance requirements and prolonged service life of their piping systems, translating into significant cost savings and operational efficiency. In conclusion, slip on pipe couplings represent a vital component in modern piping systems, valued for their simplicity, flexibility, and robust performance characteristics. Selecting the appropriate coupling involves considering factors such as material compatibility, environmental conditions, and adherence to relevant industry standards. By emphasizing experience, expertise, authority, and trust, professionals can make informed decisions that optimize the functionality and longevity of their piping systems, thus advancing operational excellence in their respective fields.

Authoritativeness is established through adherence to industry standards, which ensures that slip on pipe couplings meet stringent safety and performance criteria. Reputable manufacturers often adhere to standards such as the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM), which guarantee that the couplings conform to specific design, performance, and safety benchmarks. Ensuring compliance with such standards is crucial for maintaining the integrity of piping systems, especially in critical applications like those found in the oil and gas sector. The trustworthiness of slip on pipe couplings is further reinforced by their proven track record in various applications around the globe. With advancements in manufacturing techniques and materials, these couplings continue to evolve, offering enhanced performance and reliability. Companies investing in high-quality slip on pipe couplings benefit from reduced maintenance requirements and prolonged service life of their piping systems, translating into significant cost savings and operational efficiency. In conclusion, slip on pipe couplings represent a vital component in modern piping systems, valued for their simplicity, flexibility, and robust performance characteristics. Selecting the appropriate coupling involves considering factors such as material compatibility, environmental conditions, and adherence to relevant industry standards. By emphasizing experience, expertise, authority, and trust, professionals can make informed decisions that optimize the functionality and longevity of their piping systems, thus advancing operational excellence in their respective fields.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025