sae j1401 brake hose specifications

Understanding SAE J1401 Brake Hose Specifications

The SAE J1401 standard, developed by the Society of Automotive Engineers (SAE), outlines the essential requirements and testing methods for hydraulic brake hose assemblies, specifically for use in automotive applications. This standard plays a crucial role in ensuring the safety and reliability of brake systems in various vehicles, including cars, trucks, and commercial vehicles.

Importance of Brake Hose Specifications

Brake hoses are a vital component of a vehicle's braking system. They transport brake fluid from the master cylinder to the brake calipers or wheel cylinders. Given the stringent performance demands placed on brake systems, the integrity of brake hoses is paramount. The SAE J1401 standard ensures that the hoses can withstand extreme conditions such as high temperatures, pressures, and exposure to various environmental factors.

Key Components of SAE J1401

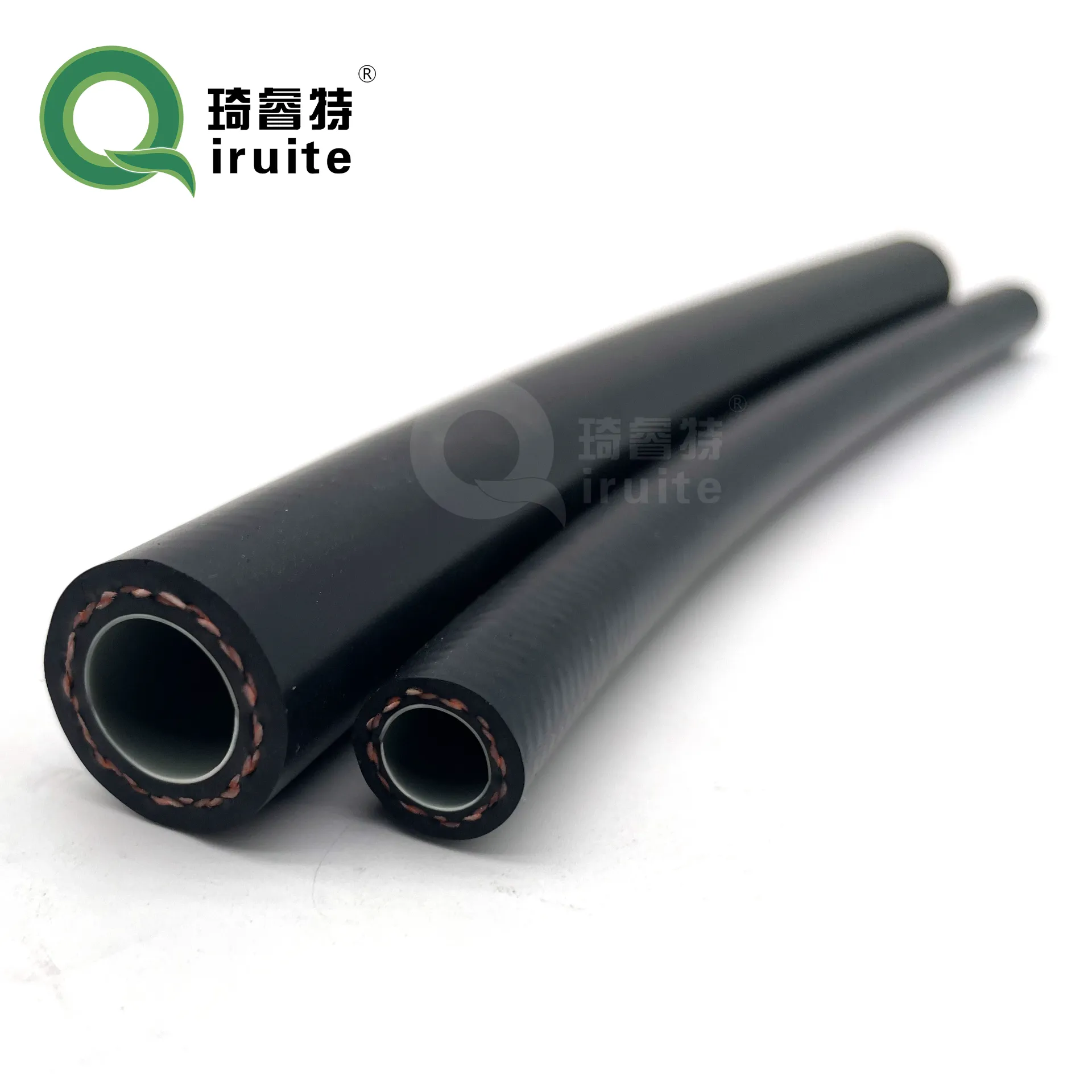

1. Material Requirements The materials used in the construction of brake hoses must be resistant to oils, fuels, and weathering. The inner tube is typically made of a synthetic rubber or thermoplastic that provides excellent hydraulic performance. The outer cover, which protects the inner tube, must be durable and resistant to abrasion and wear.

2. Construction Standards The brake hoses outlined in the SAE J1401 standard should consist of a minimum of two layers an inner tube and one or more layers of reinforcement. This reinforcement is often made from high-strength synthetic fibers or steel wire braiding, which helps maintain the hose's integrity under high pressure and ensures minimal expansion during operation.

sae j1401 brake hose specifications

3. Performance Testing To meet SAE J1401 specifications, brake hoses must undergo rigorous performance testing, including burst pressure tests, impulse tests, and environmental resistance tests. These tests simulate the real-world conditions a hose may encounter over its lifecycle, ensuring that it can handle the stresses of operation and prevent failure.

4. Temperature and Pressure Ratings SAE J1401 specifies that the hoses must be capable of operating effectively within certain temperature and pressure ranges. Typically, the standard requires hoses to withstand temperatures from -40°C to +100°C while maintaining performance at a specified burst pressure. This is especially critical in high-performance and heavy-duty vehicles where the braking system can generate significant heat.

5. Marking and Identification Each brake hose assembly must be clearly marked to indicate that it meets SAE J1401 specifications. This includes information about the manufacturer, date of manufacture, and compliance with the standard. Proper labeling is essential for traceability and ensures that users can verify the quality and compliance of the hoses they are using.

Applications and Compliance

The SAE J1401 standard is commonly applied in automotive brake systems, but it also extends to motorcycles and some industrial applications. Manufacturers of hydraulic brake hoses must ensure that their products meet or exceed these specifications to gain acceptance in the market. Compliance with SAE J1401 not only enhances the product's credibility but also assures customers of its safety and reliability.

Conclusion

In conclusion, the SAE J1401 brake hose specifications represent a critical component of vehicle safety and performance. As the automotive industry continues to evolve with advancements in technology and increased emphasis on safety, adherence to these standards will remain essential. For consumers, understanding these specifications can aid in making informed choices about the replacement and maintenance of brake components, ultimately ensuring safer driving experiences. Manufacturers, too, benefit from compliance as it promotes trust in their products and mitigates risks associated with brake failures. The SAE J1401 standard is, therefore, a cornerstone in the framework of automotive safety regulations, reflecting the industry's commitment to quality and reliability in brake system performance.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025