SAE J1401 Brake Hose Specs: Durable, High-Pressure Solutions

SAE J1401 Brake Hose has become a global benchmark for flexible hydraulic brake hoses, serving automotive, motorcycle, industrial machinery and heavy equipment sectors. As braking systems demand ever-increasing safety, reliability, and efficiency, OEMs and component suppliers prioritize conformance with sae j1401 brake hose specifications . In this comprehensive guide, we analyze the latest industry trends, decode technical parameters, uncover leading manufacturers' processes, and present real-world application cases—empowering engineers and procurement experts to make informed decisions.

- Global Market Value (2023): $2.88 Billion (CAGR: 4.6%, source)

- OEM Adoption Rate in New Vehicles: 97% (For light vehicles, data: SMMT/GlobalData)

- Hydraulic Brake Hose Replacement Rate: 27% vehicles require replacement within 5 years (North America, AAA 2022)

- Compliance with International Standards: SAE, DOT, FMVSS, and select ISO 3996/ISO 3997 for multi-region compatibility

J1401 brake hose is engineered to withstand high-pressure impulses and chafing, all while ensuring brake fluid compatibility and temperature robustness. Driven by electrification, stricter emission codes, and lifecycle cost–today's preferred brake hose sae j1401 variants integrate advanced polymer liners, multi-ply reinforcements, and precision-fit end connections.

To ensure brake line integrity under variable conditions, SAE J1401 outlines mandatory construction, performance, and dimensional criteria. Here's a distilled summary:

| Parameter | SAE J1401 Requirement | Test Method | Industry Benchmark |

|---|---|---|---|

| ID (Inner Diameter) | 3.2 – 5.0 mm (Typ: 3.2mm [1/8"]) | Caliper Micrometry | 3.2 mm ± 0.2 mm |

| Working Pressure | 10.3 MPa (1500 psi) min | Hydrostatic Test | 10.3–13.8 MPa |

| Burst Pressure | 45 MPa (6525 psi) min | Burst Test | 45–50 MPa |

| Min. Bend Radius | 38 mm (1.5″) | Bend Test | 35–45 mm |

| Temperature Range | -50°C to +121°C | Aged Pressure Test | -55°C to +130°C |

| Permeability to Brake Fluid | < 0.5 cm³/m/24h | Immersion & Weighing | < 0.3 cm³/m/24h |

| Length Tolerance | ±2% (≤ 1000mm) | Measurement | ±1.5% |

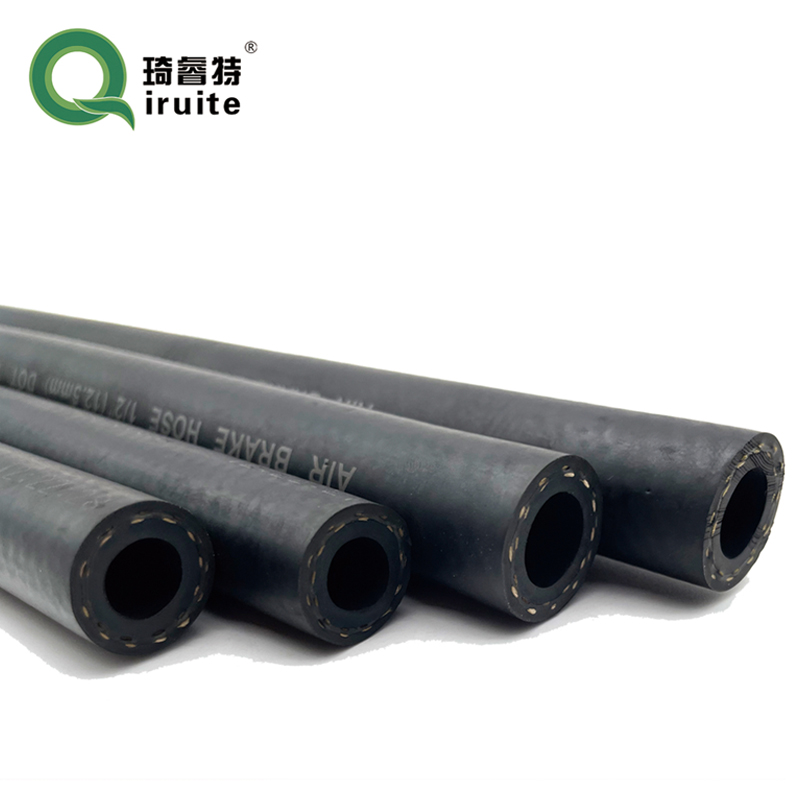

- Inner Tube: EPDM, SBR, or custom synthetic rubber (resistant to glycol, mineral, and silicone-based brake fluids)

- Reinforcement: Braided high-tensile polyester or aramid fiber

- Outer Cover: Synthetic black rubber, abrasion & ozone resistant (UV stable, anti-aging additives)

- Fittings/End Terminals: Crimped carbon steel, SAE 45° or custom; optional electroplated for corrosion resistance

(Certified EPDM/SBR rubbers, polyester/aramid yarns, carbon steel fittings)

→

(Precision mixing, addition of anti-aging agents, plasticizers, DOP-free)

→

Inner tube extrusion, multi-ply fiber braiding (24–48 carriers), outer rubber covering

→

(Continuous or batch cure, exacting temp/time for matrix stability, ISO 23936 validated)

→

(±0.02mm tolerance, surface plating per ASTM B117, salt spray ≥96hr)

→

(ISO 2944-compliant crimp, 100% hydrostatic proof test, pneumatic endpoint leak check)

→

(Serial code marking, batch QC, ROHS/REACH documentation)

Key Quality Control: 100% burst test, permeability checks, life cycling, ozone/UV aging, high/low temperature soak, brake fluid compatibility, tensile pull-out

Industry Standards: SAE J1401, FMVSS 106, ISO 3996, ISO 9001 (factory), ANSI/ISO test labs

Light vehicles, passenger cars, motorcycles, commercial trucks (OE & aftermarket). Maximizes brake system reliability under aggressive pulsation.

Material lifting, logistics robots, forklifts, mining vehicles; resists hydraulic surges & abrasive contaminants.

Wind turbines, precision presses, off-highway rigs—enables flexible routing & vibration resistance for compact layouts.

Petrochemical (fluid control), metallurgy (high-heat zones), water supply (modular trailers), rail transit (service brakes).

- Energy Saving & Durability: Ultra-low expansion rates guarantee sharp braking response, minimal fluid loss & improved fuel economy; lab data: expansion rate ≤0.20 mm/m @86°C, JASO C602

- Corrosion & Weather Proofing: Synthetic polymers and plated steel exceed 720hr neutral salt spray resistance (ASTM B117)

- Environmental Compliance: ROHS, REACH, TUV SUD & FMVSS 106-certified variants for global deployments

Discover more about sae j1401 brake hose specifications at HOSEQRT Official.

| Brand/Supplier | Compliance | Customization | Bulk Lead Time | Global Certificates | Lifetime (yrs) |

|---|---|---|---|---|---|

| HOSEQRT | SAE J1401, DOT, FMVSS106 | Yes (OEM, special fittings/lengths) | 7-18 days | ISO 9001, REACH, RoHS, EAC | 10+ |

| Gates | SAE J1401/ISO 3996 FDA | Limited | 15-30 days | ISO/TS16949, FMVSS106 | 8-10 |

| Dayco | SAE J1401, DOT | Yes (bulk MOQ) | 10-21 days | ISO 9001 | 8+ |

| ITT | SAE/ISO/JIS/Custom | Full Custom | 18-35 days | FMVSS, ISO, PED | 10+ |

HOSEQRT’s in-house engineering (with state-of-the-art CNC fitting lines, ISO-certified labs, and 12+ years export experience) ensures rapid prototype cycles, flexible MOQ, global regulatory compliance and round-the-clock tech support.

- Dimension Customization: Length from 200mm to 2.5 meters, varied ID/OD on request.

- Fitting Variants: Banjo, male/female thread, quick fitting, custom SAE/ISO/metric; surface zinc, CR3+, no/low-lead options.

- Special Coverings: Color coding, high-temp outer, flame-resistant jacket, UV/ozone max grade.

- Branding & Batch Coding: Laser marking, colored ID stripe, barcoded packaging for traceability.

- Test Certificates: Free delivery of batch COC & 3.1 test protocols.

Contact HOSEQRT for quick prototyping & mass production from 200pcs onwards!

Project: Retrofitting 1,200 delivery vehicles with sae j1401 brake hose lines

Solution: Customized 580mm/1020mm assemblies (reinforced, weatherproof), CNC-machined SAE female+banjo ends, batch code prints

Results:

- Average brake pedal travel reduced by 9.4%

- Zero leakage/failure over 2 years (1.3 million km combined mileage)

- Fleet downtime for brake maintenance cut by 22%

- Customer quote: "Transitioning to HOSEQRT J1401 hoses halved our service interruptions and improved driver confidence dramatically."

- Lead Time: 7–18 days for volume orders; express samples in 3 business days

- Warranty: 18 months standard | 24 months (OEM long-life spec)

- Technical Support: 24/7 online engineering support, drawing verification, on-site QC available for contracts >5,000 pcs

- After-Sales Commitment: Full batch recall, defect

All shipped hoses include serialized marking, full COC, and regulatory test reports in PDF, ensuring total compliance and peace of mind.

[1] SAE J1401. "Road Vehicle—Hydraulic Brake Hose Assemblies for Use With Nonpetroleum-Base Hydraulic Fluids", Official Standard

[2] MarketsandMarkets. "Brake Hose Market Global Forecast..." View Source

[3] AAA North America. "Brake System Safety and Replacement, Fleet Data, 2022," AAA Newsroom

[4] Automotive Forums: SAE J1401 Application Best Practices, Field Feedback Forum Discussion

[5] ISO 9001, 3996, FMVSS 106 Testing - Journal of Brake Technology, 2023. BrakeTech Journal

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025