r134a service hose

Understanding R134a Service Hoses A Comprehensive Overview

The R134a refrigerant, also known as tetrafluoroethane, has become a standard in automotive air conditioning systems since it replaced the more harmful R12 refrigerant. Handling R134a necessitates specialized equipment, including a service hose designed to manage the unique properties of this refrigerant. In this article, we delve into the essential aspects of R134a service hoses, their construction, usage, and maintenance practices to ensure optimal performance and safety.

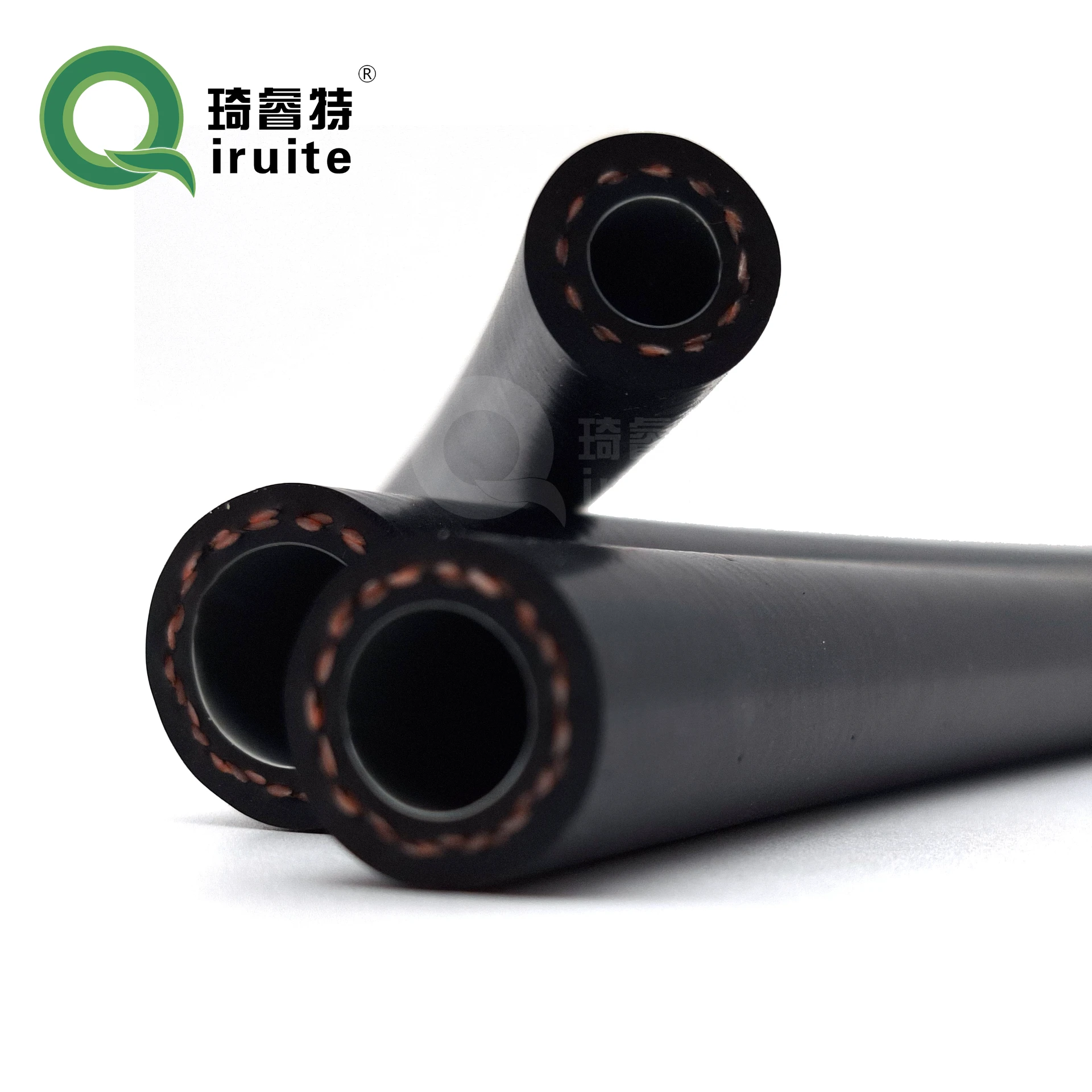

Construction of R134a Service Hoses

R134a service hoses are specifically engineered to accommodate the pressures and temperatures associated with refrigerants. These hoses are typically made from materials that can withstand external wear and high internal pressures, such as rubber reinforced with synthetic fibers or thermoplastic elastomers. The fittings at the ends of the service hoses are usually designed to connect seamlessly with manifold gauge sets and the vehicle's AC ports. These connections must be secure to prevent leaks and ensure efficient refrigerant flow.

Types of R134a Service Hoses

There are various types of service hoses available, each suited for different applications. The most common include

1. Low-Pressure Hoses These are used for the suction side of the air conditioning system and generally carry refrigerant in a gaseous state. The low-pressure hose is usually distinguished by its larger diameter compared to the high-pressure hose.

2. High-Pressure Hoses These carry refrigerant in a liquid state from the condenser to the expansion valve. High-pressure hoses have a smaller diameter and are built to handle the elevated pressures without risk of bursting.

3. Refrigerant Recovery Hoses These hoses are specifically designed for refrigerant recovery during servicing. They come with specialized fittings to connect to recovery machines, ensuring that refrigerants are safely removed from the system.

r134a service hose

Usage and Best Practices

When using R134a service hoses, proper practices are critical to ensure safety and performance. Always inspect hoses for signs of wear, cracks, or leaks before use. Utilizing the correct hose for the specific application (low or high pressure) is equally essential. Improper connections can lead to refrigerant loss, system inefficiency, and potential hazards.

Furthermore, when connecting hoses, ensure that the fittings are tightened adequately but not overtightened to avoid damage. Upon completion of a service, it's crucial to visually check all connections for possible leaks before recharging the air conditioning system.

Maintenance and Care

To prolong the life of R134a service hoses, regular maintenance is vital. Store hoses in a cool, dry place away from direct sunlight and sharp objects. After use, it is advisable to purge hoses of any remaining refrigerant, as this helps prevent contamination and prolongs the overall lifespan of the equipment.

In addition, periodic thorough inspections should be conducted to identify any signs of wear or potential failures. Replacement of damaged hoses should be done immediately to prevent any operational issues.

Conclusion

R134a service hoses play a crucial role in the maintenance and functioning of automotive air conditioning systems. By understanding their construction, types, and best practices for usage and maintenance, technicians can ensure efficiency, safety, and reliability in automotive HVAC services. Proper handling of these components not only contributes to effective refrigerant management but also supports environmental goals by minimizing refrigerant leaks and ensuring compliance with regulatory standards.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025