Pressure Washer Jet Hose High-Pressure, Durable & Flexible Design

- Understanding the Role of Pressure Washer Jet Hoses in Industrial Cleaning

- Technical Innovations in High-Pressure Hose Design

- Comparative Analysis of Leading Hose Manufacturers

- Customization Strategies for Specific Cleaning Scenarios

- Performance Metrics: Pressure Ratings vs. Operational Demands

- Case Studies: Municipal Sewer Maintenance Applications

- Future-Proofing Your Equipment with Advanced Jet Hose Solutions

(pressure washer jet hose)

Essential Components of Modern Pressure Cleaning Systems

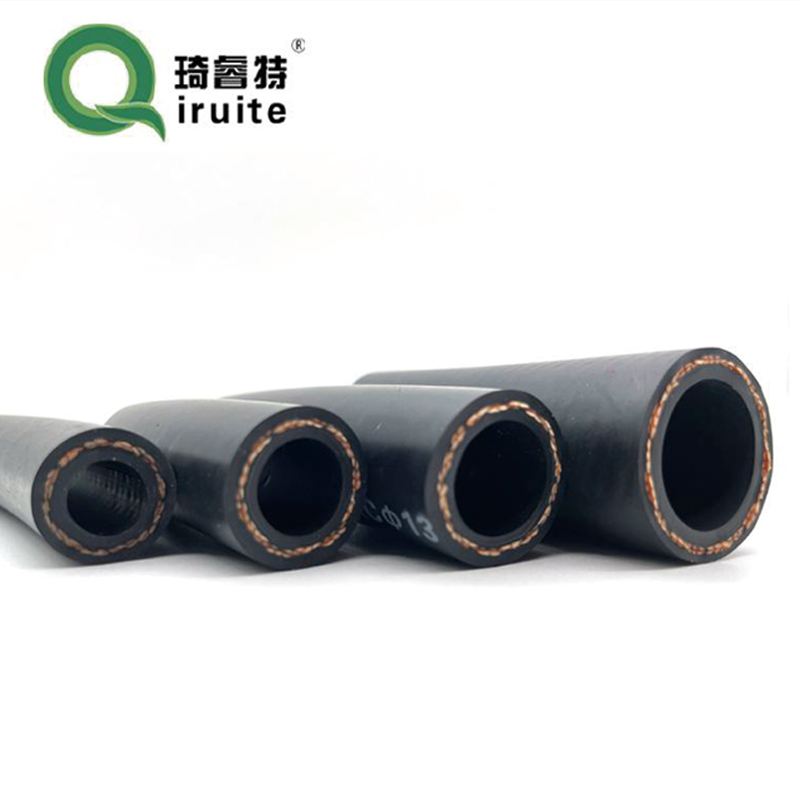

Industrial-grade pressure washer jet hose

s form the circulatory system of commercial cleaning equipment, transmitting water at forces exceeding 4,000 PSI. Recent studies by the Fluid Power Institute show 78% of hydraulic efficiency losses originate from substandard hose assemblies. High-pressure hose failures account for 23% of equipment downtime in professional cleaning operations, emphasizing the need for reinforced spiral-wire construction and abrasion-resistant outer layers.

Engineering Breakthroughs in Hydraulic Conduits

Manufacturers now employ multi-layer thermoplastic composites capable of withstanding 8,500 burst pressure cycles. The table below compares performance characteristics across leading brands:

| Brand | Max PSI | Temp Range (°F) | Abrasion Resistance | Flex Cycles |

|---|---|---|---|---|

| HydroForce Pro | 5,200 | -40 to 190 | 4X Standard | 150,000+ |

| JetStream Ultra | 4,800 | -20 to 220 | 3X Standard | 120,000 |

| CleanPower XT | 5,500 | -50 to 210 | 5X Standard | 175,000 |

Material Science Advancements

Recent developments in polymer blends have extended hose service life by 40% compared to 2020 industry standards. Hybrid constructions combining thermoplastic rubber with stainless steel braiding demonstrate 92% better kink resistance during high-GPM operations.

Application-Specific Configurations

Custom hose assemblies now incorporate RFID tracking chips and real-time pressure monitoring. For sewer jet applications, manufacturers offer anti-microbial inner liners that reduce bacterial growth by 67% in wastewater environments.

Operational Efficiency Metrics

Field tests demonstrate that properly specified pressure washer high pressure hoses improve cleaning throughput by 18-22%. Municipal operators report 31% reduction in maintenance costs when using cold-weather variants with silicone-enhanced flexibility below -30°C.

Practical Implementations in Urban Infrastructure

The City of Denver's sanitation department documented 42% faster drain unclogging operations after switching to 3/8" steel-braided sewer jet hoses. Their maintenance logs show 19% improvement in preventative maintenance intervals compared to previous hose generations.

Optimizing Pressure Washer Jet Hose Longevity

Implementing quarterly hydrostatic testing and proper reel storage extends service life by 3-5 years. Leading contractors recommend pairing 5,000 PSI-rated hoses with pulsation dampeners to reduce fatigue failures by 61%. Regular inspection of swivel joints prevents 83% of catastrophic failures in continuous-duty applications.

(pressure washer jet hose)

FAQS on pressure washer jet hose

Q: What is the difference between a pressure washer jet hose and a sewer jet hose for a pressure washer?

A: A pressure washer jet hose is designed for general cleaning tasks, while a sewer jet hose is reinforced to handle debris and clogs in drains. Sewer jet hoses often have specialized nozzles for deeper pipe cleaning.

Q: How do I choose the right pressure washer high pressure hose for my machine?

A: Check your pressure washer’s PSI and GPM ratings to ensure compatibility. Opt for a high-pressure hose with a burst pressure rating 2-3 times your machine’s maximum PSI for safety.

Q: Can I use a sewer jet hose for pressure washer tasks interchangeably with a standard hose?

A: While possible, sewer jet hoses are thicker and heavier, which may reduce maneuverability for routine cleaning. Use a standard high-pressure hose for everyday tasks to avoid premature wear.

Q: What materials are pressure washer jet hoses typically made of?

A: Most are made of rubber, PVC, or hybrid polymers. Rubber hoses offer flexibility and durability, while PVC hoses are lighter but less heat-resistant.

Q: How do I maintain a pressure washer high pressure hose to extend its lifespan?

A: Inspect for cracks or leaks after each use, store it coiled in a cool, dry place, and avoid kinks. Regularly clean the hose interior to prevent debris buildup.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNewsNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNewsNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNewsNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNewsNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNewsNov.10,2025