power steering hose connections

Understanding Power Steering Hose Connections An Essential Guide

Power steering systems are critical components in modern vehicles, providing enhanced control and maneuverability. Central to this system are the power steering hoses, which play a pivotal role in delivering fluid from the pump to the steering gear. Understanding the connections involved in these hoses is crucial for vehicle maintenance and repair. In this article, we will explore the significance of power steering hose connections, their types, and common issues that may arise.

The Importance of Power Steering Hose Connections

Power steering hoses are responsible for transporting pressurized hydraulic fluid to the steering mechanism, allowing drivers to turn the steering wheel with minimal effort. The connections of these hoses ensure that fluid flows efficiently and safely, facilitating smooth steering performance. A reliable connection prevents leaks and maintains the integrity of the steering system, which is vital for vehicle safety.

Types of Power Steering Hose Connections

Power steering hoses typically feature two types of connections high-pressure and low-pressure.

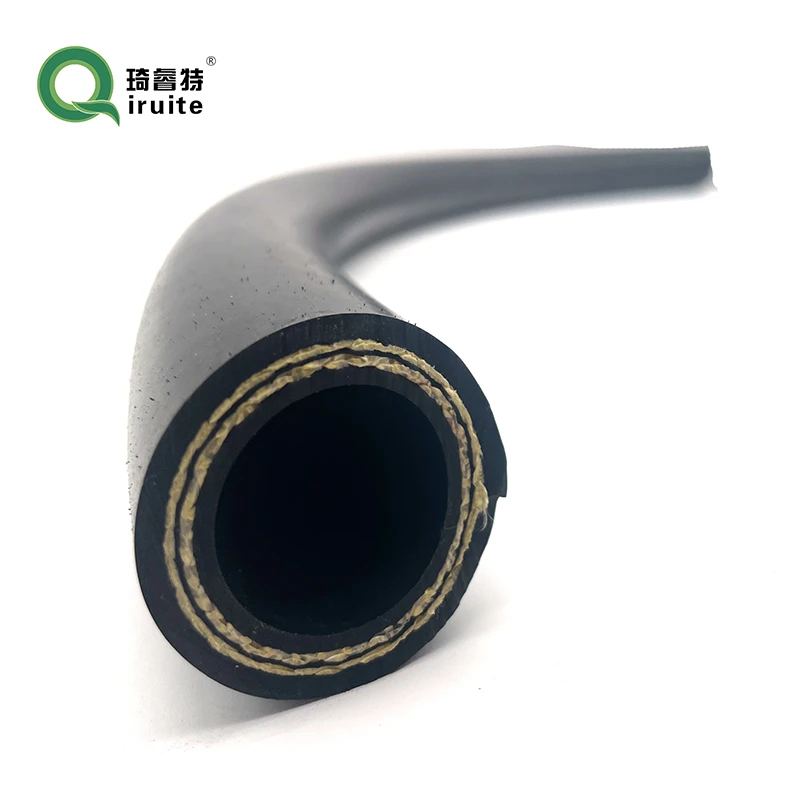

1. High-Pressure Hoses These hoses carry fluid directly from the power steering pump to the steering gear. They are designed to withstand high pressure, often exceeding 1,500 psi. High-pressure hoses are usually made of durable materials such as reinforced rubber or synthetic compounds, and their connections often feature crimped fittings to ensure a secure seal.

2. Low-Pressure Hoses These hoses return fluid from the steering gear back to the reservoir. They operate at a lower pressure compared to high-pressure hoses and are less robust in construction. Low-pressure hoses are typically made from softer materials, allowing for better flexibility, which is essential for accommodating vehicle movement and vibration.

Common Connection Types

Power steering hose connections can vary based on make and model, but several common connection types include

- O-Ring Fittings These connections use an O-ring to create a seal. The O-ring is placed in a groove in the fitting, and when the connection is tightened, it compresses the O-ring against the surface, preventing leaks.

- Compression Fittings These fittings utilize a ferrule to compress the hose against a fitting when tightened, creating a tight seal

. They are commonly used in various applications due to their reliability.power steering hose connections

- Crimped Fittings A prevalent feature in high-pressure hoses, crimped fittings are physically crimped onto the hose, ensuring a strong bond that can withstand high levels of pressure.

Common Issues with Hose Connections

Despite their robust design, power steering hose connections may experience problems over time, leading to steering issues. Common problems include

- Leakage One of the most frequent issues is fluid leakage from hose connections. This can be caused by wear and tear, improper installation, or damage to the hoses. A leak can reduce steering efficiency and may lead to a complete power steering failure if not addressed promptly.

- Corrosion Over time, connections may become susceptible to corrosion, especially in regions with harsh weather conditions. Corroded connections can weaken and ultimately fail, leading to leaks.

- Improper Torque Ensuring that hoses are tightened to the manufacturer-recommended torque specifications is crucial. Insufficient tightening can cause leaks, while over-tightening may damage the fittings.

Maintenance and Best Practices

To ensure the longevity and effectiveness of power steering hose connections, routine maintenance is essential. Drivers should regularly inspect hoses for signs of wear, leaks, or corrosion. If any damage is detected, replacing the affected hoses and fittings promptly is crucial to prevent further issues.

Additionally, when performing repairs or replacements, using manufacturer-recommended parts and following proper installation procedures can minimize the risk of future problems.

Conclusion

Power steering hose connections may seem like small components, but they are vital for the safe and efficient operation of a vehicle's steering system. Understanding their types, potential issues, and maintenance practices can help drivers keep their vehicles in optimal condition, ensuring a smooth and safe driving experience. Regular inspections and prompt repairs will go a long way in maintaining the integrity of the power steering system.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025