Power Steering Hose Crimp Fittings Overview and Installation Guide for Automotive Applications

Understanding Power Steering Hose Crimp Fittings

Power steering systems are essential components of modern vehicles that enhance the drivability and comfort of driving. At the heart of these systems lies the power steering hose, which plays a crucial role in conveying hydraulic fluid between the pump and the steering mechanism. To ensure the effective operation of this system, the connections at the ends of the hoses must be secure and leak-free. This is where power steering hose crimp fittings come into play.

What Are Power Steering Hose Crimp Fittings?

Power steering hose crimp fittings are specialized connectors that secure the power steering hose to various components, such as the power steering pump and the steering gear. Crimp fittings are designed to create a tight seal by deforming a metal sleeve around the hose, which locks the hose in place and prevents any hydraulic fluid from leaking. These fittings are typically made from robust materials like aluminum or stainless steel to withstand the high pressures generated by the hydraulic fluid.

The Importance of Proper Installation

The integrity of the power steering system hinges on the correct installation of crimp fittings. If these fittings are not crimped to the proper specifications, it can lead to several issues, including leaks, reduced steering performance, or even complete failure of the steering system. Therefore, it is imperative to utilize the right tools and adhere to manufacturer guidelines during the crimping process.

The crimping process involves using a hydraulic or mechanical crimping tool that applies uniform pressure around the fitting to create a tight seal. It is essential to ensure that the hose is adequately prepared before crimping, which includes cutting the hose to the appropriate length and removing any debris or contaminants.

Choosing the Right Fittings

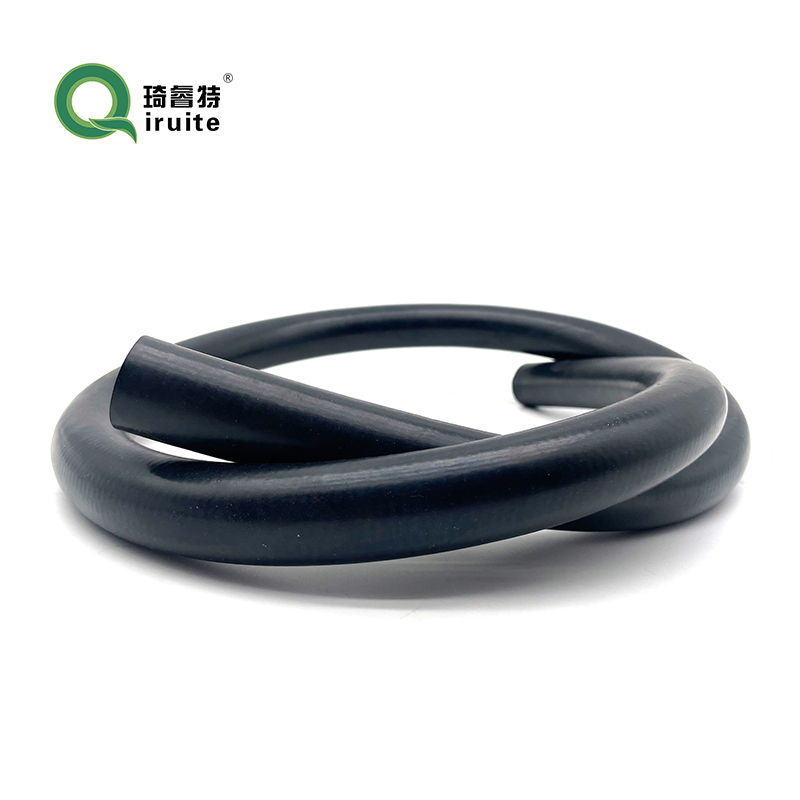

power steering hose crimp fittings

When selecting power steering hose crimp fittings, several factors should be considered. First, the material of the fitting should match the requirements of the application. For instance, stainless steel fittings are often preferred in high-performance or high-temperature scenarios due to their durability and resistance to corrosion.

Additionally, the size and type of fitting must correspond with the diameter of the hose being used and the specific threads of the connections. There are several types of crimp fittings available in the market, including straight fittings, elbow fittings, and swivel fittings, each designed for different configurations and applications.

Maintenance and Inspection

Regular maintenance of power steering systems is essential to ensure smooth and safe operation. This includes periodic inspections of the hoses and crimp fittings for any signs of wear, such as cracks, bulges, or corrosion. If any issues are detected, it is crucial to address them promptly to avoid failure while driving.

Flushing the power steering fluid and replacing it as needed can also contribute to a longer lifespan for the system. Contaminated fluid can lead to premature wear of both the hoses and fittings, compromising the integrity of the power steering system.

Conclusion

Power steering hose crimp fittings are vital components that ensure the reliability and efficiency of a vehicle's power steering system. Understanding their function, the importance of proper installation, and the need for regular maintenance can lead to improved vehicle performance. Whether you are a DIY enthusiast or a professional mechanic, taking the time to choose quality fittings and install them correctly will pay dividends in the long run, ensuring that your power steering system operates smoothly and effectively.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025