j2064 hose

The J2064 Hose A Comprehensive Guide

In the world of hydraulic systems and fluid conveyance, the J2064 hose stands out as a crucial component for various industrial applications. As a standard created by the Society of Automotive Engineers (SAE), J2064 specifies the requirements for hydraulic hoses and fittings, ensuring that they meet the high demands of different industries, including automotive, aerospace, and heavy machinery. In this article, we will delve into the characteristics, applications, and benefits of J2064 hoses.

Understanding J2064

The J2064 standard was developed to address the need for durable and effective hose assemblies that can withstand the rigors of hydraulic systems. These hoses are primarily designed for conveying hydraulic fluids under high pressure and temperature, making them integral to various machinery and equipment.

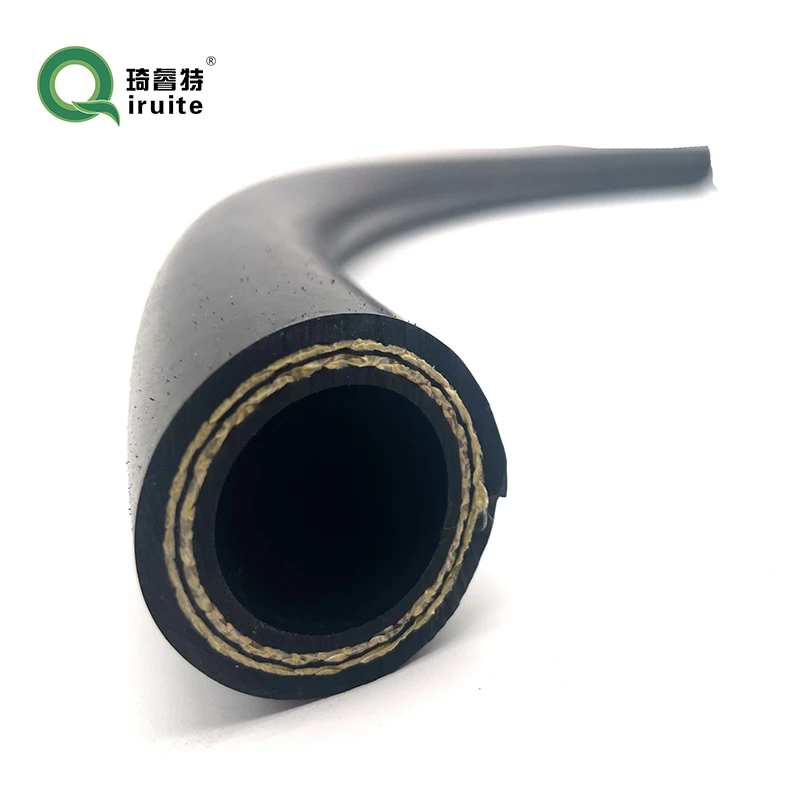

The specification covers multiple grades of hoses, catering to different pressure ratings and operational temperatures. Typically, J2064 hoses are constructed from synthetic rubber or thermoplastic materials, which provide flexibility, resistance to abrasion, and protection against external environments. Their internal structure often consists of multiple layers, including a reinforcement layer that enhances tensile strength and durability.

Key Features of J2064 Hoses

1. Temperature Resistance One of the standout features of J2064 hoses is their ability to function effectively across a broad temperature range. This characteristic is vital since hydraulic systems often operate under extreme conditions.

2. Pressure Ratings These hoses are available in various pressure ratings, allowing engineers and operators to select the right hose for their specific application. High-pressure lines can handle up to 3,000 psi, making them suitable for demanding hydraulic systems.

3. Compatibility J2064 hoses are designed to be compatible with a wide range of hydraulic fluids, including oil, water-glycol solutions, and other non-flammable fluids. This versatility simplifies the selection process for equipment manufacturers and operators.

4. Durability The robust construction of J2064 hoses ensures longevity in harsh operating conditions. They are resistant to wear, tear, and degradation caused by exposure to chemicals and environmental factors.

5. Safety Standards Adhering to J2064 specifications means that the hoses meet strict safety and performance standards. This compliance is crucial in preventing leaks and ruptures, which could lead to hazardous situations.

Applications of J2064 Hoses

The versatility of J2064 hoses makes them suitable for a multitude of applications. Several key areas of use include

j2064 hose

1. Automotive Industry In automobiles, J2064 hoses are essential for the transmission and hydraulic brake systems. They facilitate the transfer of fluids necessary for operation and safety.

2. Heavy Machinery Equipment such as excavators, bulldozers, and forklifts rely on J2064 hoses to maintain hydraulic power for lifting, digging, and moving materials.

3. Agricultural Equipment Tractors and harvesters also utilize J2064 hoses for hydraulic functions, improved efficiency, and reliability in the field.

4. Marine Applications Boats and ships employ these hoses for various hydraulic systems, including steering and propulsion, due to their resistance to saltwater corrosion.

5. Aerospace In aerospace applications, J2064 hoses play a significant role in hydraulic systems that control flight surfaces and landing gear, emphasizing their critical importance in high-stakes environments.

Benefits of Using J2064 Hoses

Utilizing J2064 hoses offers numerous advantages

- Enhanced Performance Engineered for optimal fluid flow and pressure, these hoses improve overall system efficiency.

- Reduced Downtime The durability and reliability of J2064 hoses minimize the risk of failures, leading to less operational downtime for maintenance and repairs.

- Cost-Effectiveness While the initial investment may be higher, the longevity and reduced maintenance costs make J2064 hoses a smart financial choice over time.

- Safety Assurance The adherence to established safety standards enhances user confidence and helps to prevent accidents resulting from hose failures.

In conclusion, the J2064 hose is an indispensable element in the hydraulic systems used across many industries. Its robust design, compatibility, and adherence to safety standards ensure that it meets the demanding needs of modern machinery and equipment. Whether in automotive, industrial, agricultural, or aerospace applications, understanding and utilizing J2064 hoses can lead to improved performance, safety, and efficiency in operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025