hyd hose fittings

Understanding Hydraulic Hose Fittings A Comprehensive Overview

Hydraulic systems play a crucial role in various industrial applications, and hydraulic hose fittings are essential components that ensure these systems function efficiently and safely. Hydraulic hose fittings are used to connect hoses, tubes, and pipes, enabling the transfer of fluids under high pressure.

Types of Hydraulic Hose Fittings

Hydraulic fittings come in several configurations and types, which can be categorized based on their design, materials, and applications. The most common types of hydraulic fittings include

1. NPT (National Pipe Thread) Fittings These fittings feature tapered threads that create a seal when tightened. They are widely used in various applications due to their effective sealing capabilities.

2. BSP (British Standard Pipe) Fittings Similar to NPT but with parallel threads, BSP fittings are common in Europe and are known for their versatility in different applications.

3. JIC (Joint Industry Council) Fittings Characterized by a 37-degree flare, JIC fittings are designed to connect hoses and rigid tubes. They provide a tight seal and are used in automotive and aerospace applications.

4. ORFS (O-Ring Face Seal) Fittings These fittings feature an O-ring that provides a reliable seal between the fitting and the hose. This design reduces the risk of leaks, making them suitable for high-pressure applications.

5. SAE (Society of Automotive Engineers) Fittings SAE fittings come in various configurations and are often used in automotive systems. They also feature a 37-degree flare or a straight thread.

hyd hose fittings

Materials and Durability

Hydraulic fittings are typically made from high-strength materials such as stainless steel, carbon steel, or brass. The choice of material depends on the specific application, environmental conditions, and fluid types being transferred.

- Stainless Steel Known for its corrosion resistance, stainless steel fittings are ideal for harsh environments or where cleanliness is essential, such as in food processing or pharmaceutical industries.

- Carbon Steel Often coated for additional protection, carbon steel fittings are cost-effective and widely used in construction and agricultural machinery.

- Brass Brass fittings offer good corrosion resistance and are commonly used in lower-pressure applications, such as HVAC systems and plumbing.

Importance of Proper Connection

Proper installation and connection of hydraulic hose fittings are critical to ensure system safety and efficiency. A poorly installed fitting can lead to leaks, which can compromise system performance and pose safety hazards. It is vital to follow manufacturer guidelines for torque specifications and to regularly inspect connections for signs of wear or damage.

Conclusion

In conclusion, hydraulic hose fittings are vital components that contribute significantly to the performance of hydraulic systems. With various types, materials, and designs available, it is essential for users to understand their specific applications and requirements when selecting fittings. Proper installation and maintenance of these fittings are crucial to ensure optimal functionality and safety in hydraulic systems. By taking the time to choose the right hydraulic hose fittings, users can enhance the durability and efficiency of their equipment, ultimately leading to increased productivity and reduced downtime.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

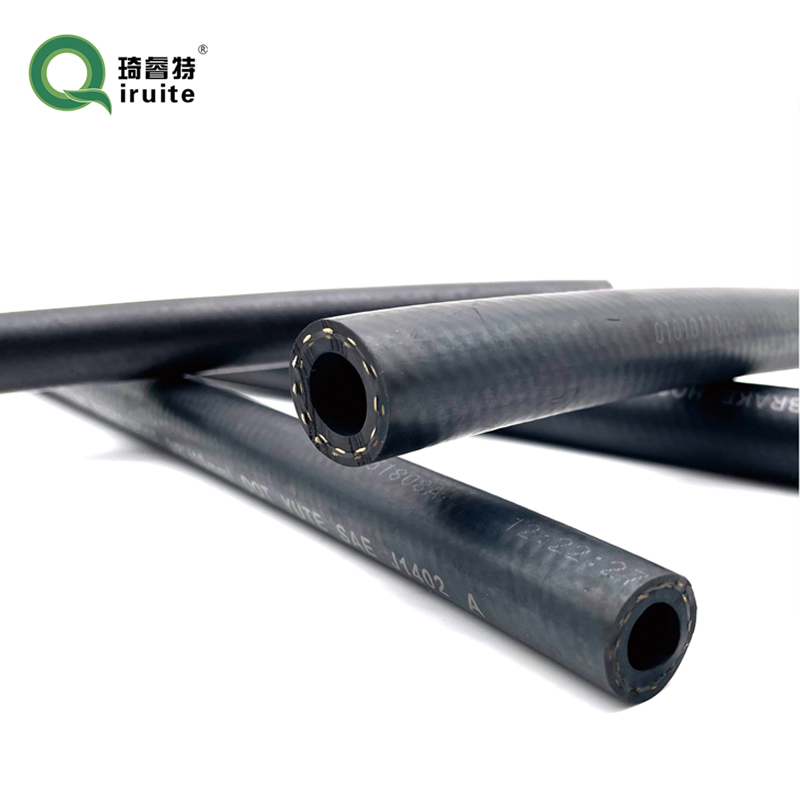

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025