Feb . 19, 2025 03:47

Back to list

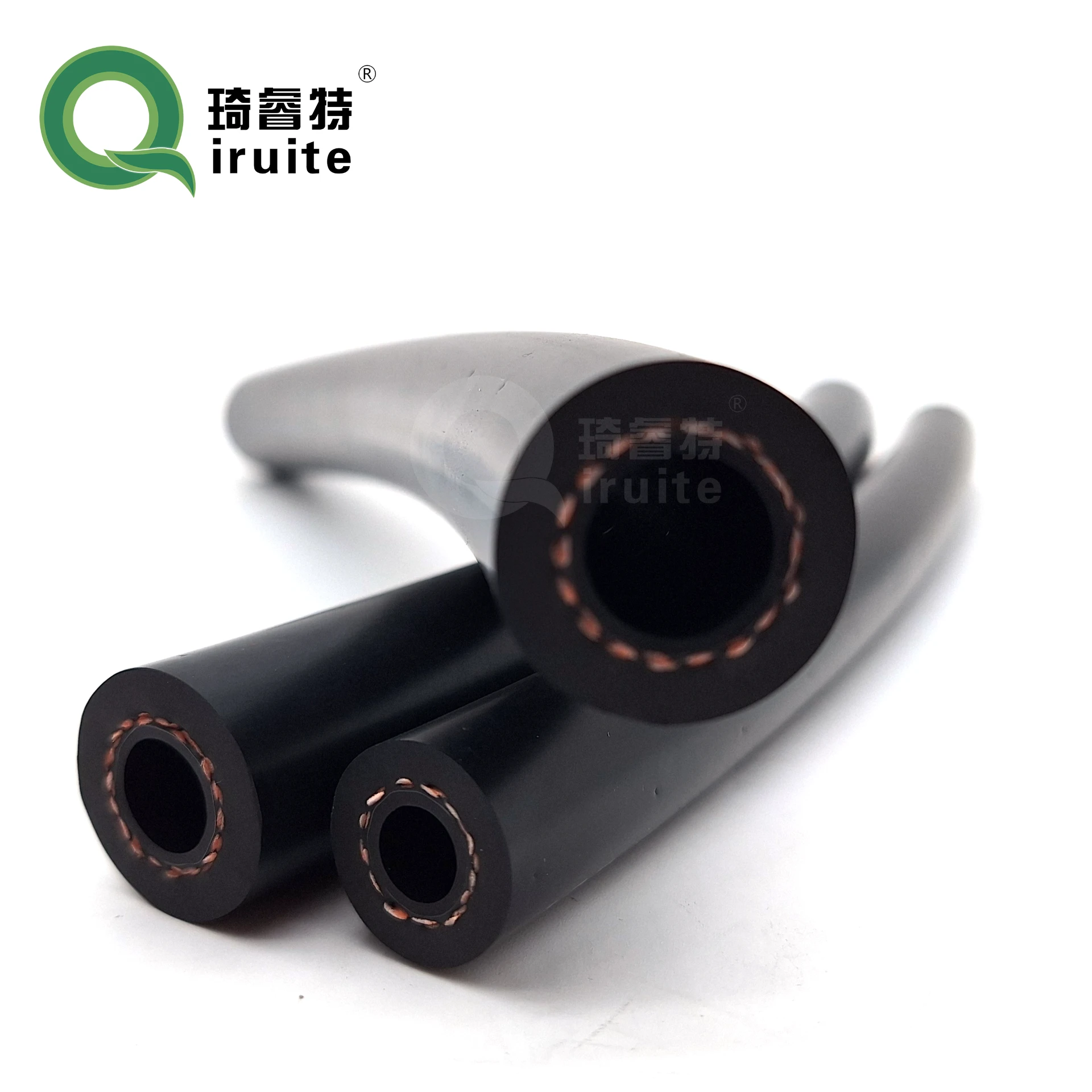

high pressure water jet hose

Understanding the pressure levels in a power steering hose is crucial for vehicle owners who wish to maintain the efficiency and longevity of their car's steering system. The pressure in a power steering hose is a determinant factor in the overall performance of a power steering system, which relies on hydraulics to operate smoothly.

Authoritative sources on vehicle maintenance advise that power steering hoses be checked periodically, ideally anytime you perform regular vehicle servicing. Expertise in automotive repair suggests that if any signs of leakage or wear are detected, hoses should be replaced immediately with original equipment manufacturer (OEM) parts or high-quality aftermarket components that meet or exceed OEM specifications. Using compatible parts ensures the hose's pressure rating matches the system's requirements, maintaining the performance and safety of the vehicle. Trustworthy reports from automotive testing organizations highlight how improper installation of power steering hoses can also lead to pressure loss. Ensuring that hoses are correctly positioned and secured, without being twisted or bent beyond their tolerance, helps maintain the system’s integrity. Both the high-pressure feed hose and the return hose must be fitted properly to avoid any potential failure points that could lead to reduced pressure and steering difficulties. In conclusion, the pressure within a power steering hose plays a pivotal role in a vehicle's steering performance. By understanding the importance of high-quality materials, regular maintenance, and correct installation, vehicle owners can trust in the longevity and reliability of their power steering systems. Investing time and effort in maintaining the optimal pressure within the power steering system ensures safe and responsive handling, enhancing the driving experience substantially.

Authoritative sources on vehicle maintenance advise that power steering hoses be checked periodically, ideally anytime you perform regular vehicle servicing. Expertise in automotive repair suggests that if any signs of leakage or wear are detected, hoses should be replaced immediately with original equipment manufacturer (OEM) parts or high-quality aftermarket components that meet or exceed OEM specifications. Using compatible parts ensures the hose's pressure rating matches the system's requirements, maintaining the performance and safety of the vehicle. Trustworthy reports from automotive testing organizations highlight how improper installation of power steering hoses can also lead to pressure loss. Ensuring that hoses are correctly positioned and secured, without being twisted or bent beyond their tolerance, helps maintain the system’s integrity. Both the high-pressure feed hose and the return hose must be fitted properly to avoid any potential failure points that could lead to reduced pressure and steering difficulties. In conclusion, the pressure within a power steering hose plays a pivotal role in a vehicle's steering performance. By understanding the importance of high-quality materials, regular maintenance, and correct installation, vehicle owners can trust in the longevity and reliability of their power steering systems. Investing time and effort in maintaining the optimal pressure within the power steering system ensures safe and responsive handling, enhancing the driving experience substantially.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025