Spiral Tubing Solutions for Efficient Hose Wrapping and Organization

Hose Wrap Spiral Tubing The Ultimate Solution for Hose Protection and Organization

In various industries, including automotive, agriculture, and construction, hoses play a critical role in conveying fluids, gases, and other materials. However, these hoses are often exposed to the elements, potential abrasions, and tangling during use or storage. To address these challenges, hose wrap spiral tubing has become an invaluable tool, providing both protection and organization.

What is Hose Wrap Spiral Tubing?

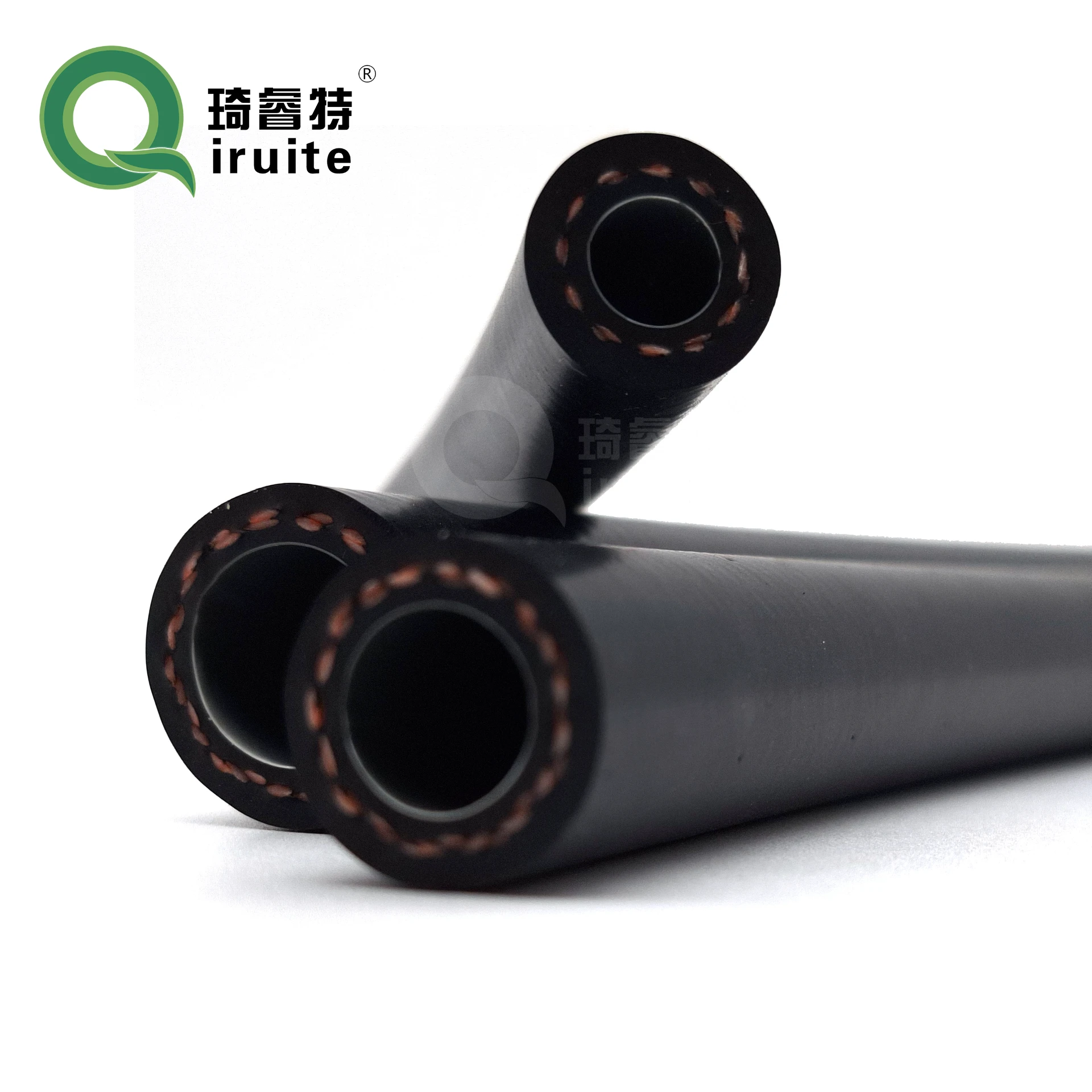

Hose wrap spiral tubing is a protective cover designed specifically for hoses. Typically made from durable materials such as polyethylene, polyurethane, or nylon, this tubing is crafted in a spiral form that allows it to wrap around hoses of various sizes. The unique design ensures that the tubing fits snugly, offering protection against abrasion, cuts, and other forms of damage that could compromise the hose's integrity.

Benefits of Using Hose Wrap Spiral Tubing

1. Protection Against Wear and Tear One of the most significant advantages of hose wrap spiral tubing is its ability to protect hoses from abrasions and environmental elements. Hoses often come into contact with rough surfaces, sharp edges, and moving machinery, which can lead to premature wear. By encasing the hose in spiral tubing, you create a protective barrier that significantly extends the lifespan of the hose.

2. Prevention of Kinking and Tangling Hoses can easily become kinked or tangled, especially when stored improperly or during transport. Hose wrap spiral tubing minimizes this risk by keeping hoses organized and separated. This not only improves efficiency during use but also ensures that the hoses remain functional and ready for action when needed.

hose wrap spiral tubing

3. Enhanced Safety In many industrial applications, hoses carry hazardous materials. Using spiral tubing provides an additional layer of safety by containing leaks and helping prevent exposure to potentially dangerous substances. Additionally, the brightly colored options available can enhance visibility, reducing the risk of accidents in busy work environments.

4. Easy Installation and Adjustability One of the key features of hose wrap spiral tubing is its ease of use. The spiral design allows for quick installation and removal, making it adaptable to various hose sizes and applications. Users can easily cut the tubing to the desired length, ensuring a custom fit for their specific needs.

5. Aesthetic Improvement Beyond practicality, hose wrap spiral tubing also offers an aesthetic improvement for workspaces. Instead of a chaotic maze of hoses, a neatly wrapped and organized appearance creates a more professional look. This can be especially important in customer-facing industries where presentation matters.

Applications of Hose Wrap Spiral Tubing

Hose wrap spiral tubing is used across diverse sectors. In the automotive industry, it protects air conditioning and fuel hoses from heat and abrasion. In agriculture, these tubes safeguard irrigation hoses, ensuring they withstand outdoor conditions. Construction sites also benefit from spiral tubing, as it helps organize and protect a multitude of hoses used for various machinery.

Conclusion

Hose wrap spiral tubing is an essential investment for any industry that relies on hoses. From protecting against wear and enhancing safety to providing an organized and aesthetically pleasing work environment, the benefits are clear. Businesses looking to prolong the lifespan of their hoses while improving efficiency and safety should consider integrating hose wrap spiral tubing into their operations. With its multitude of advantages, this simple yet effective solution is set to become a staple in hose management and protection strategies across industries. Whether in a bustling workshop or a vast agricultural field, hose wrap spiral tubing ensures that hoses work harder, last longer, and remain safe – an indispensable tool for modern operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025