Durable Protection Wrap for Hoses to Enhance Longevity and Prevent Damage

The Importance of Hose Protector Wraps in Various Industries

In industries where hoses are an integral component of machinery and equipment, ensuring their longevity and functionality is crucial. Hose protector wraps are designed specifically for this purpose, acting as a shield against a variety of environmental hazards that could potentially damage hoses. This article delves into the significance of hose protector wraps, their applications, and the benefits they offer across different sectors.

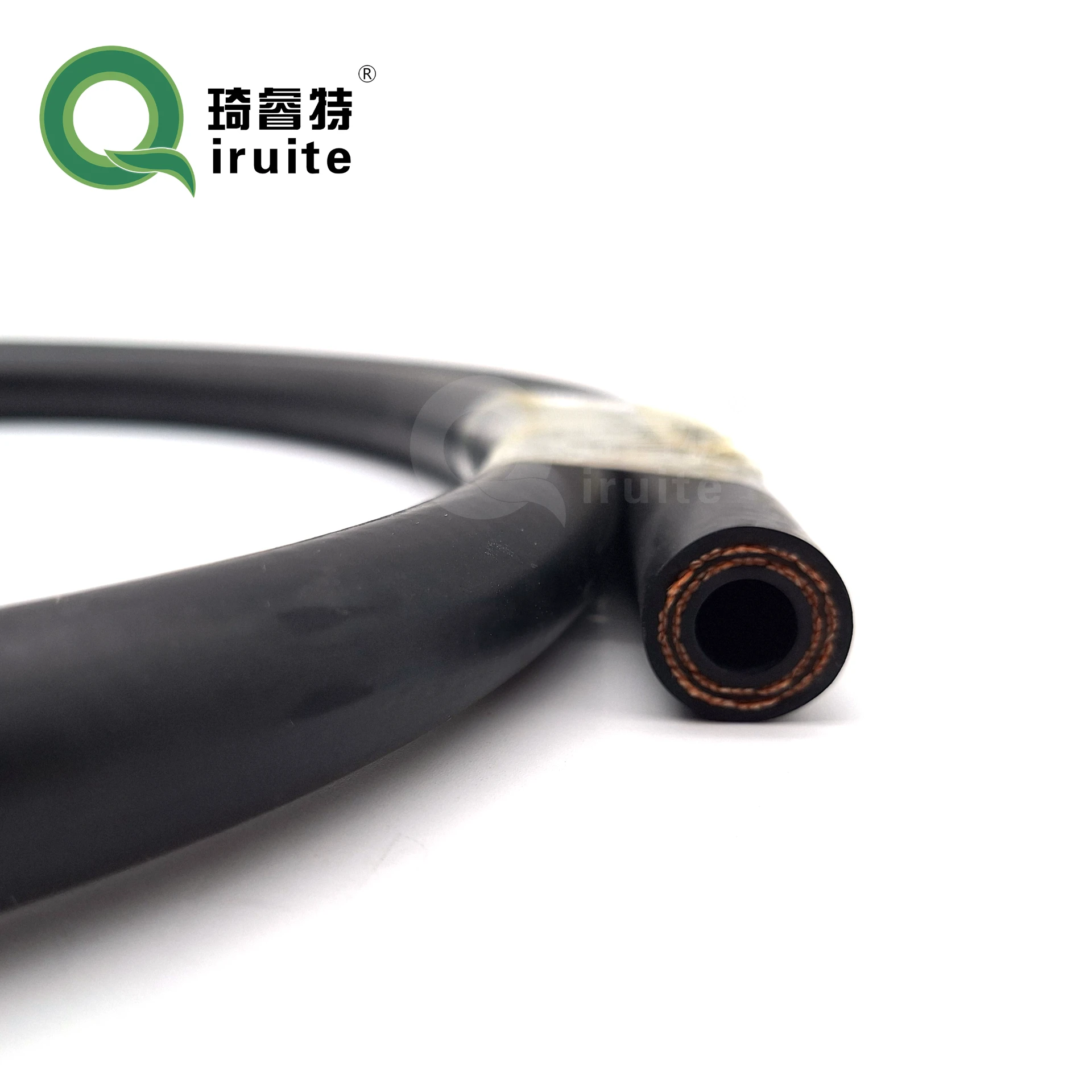

Understanding Hose Protector Wraps

Hose protector wraps are typically made from durable materials such as nylon, polyethylene, or rubber, which are selected for their strength and resistance to wear and tear. These wraps are designed to encase hoses, providing a protective layer that prevents abrasions, cuts, and other forms of wear that can shorten the lifespan of hoses. In addition, they can shield hoses from environmental factors like UV radiation, extreme temperatures, and chemical exposure.

Key Applications

1. Manufacturing and Production In manufacturing facilities, hoses are often subjected to rough handling and exposure to industrial environments. Hose protector wraps help protect against mechanical wear caused by machinery, allowing hoses to operate efficiently and reducing maintenance downtime.

2. Construction The construction industry relies heavily on hoses for various equipment, including hydraulic systems and pneumatic tools. Protector wraps are essential in preventing damage from sharp objects, rocks, or extreme weather conditions, ensuring that construction projects proceed smoothly without unexpected interruptions.

3. Agriculture In agricultural settings, hoses are used for irrigation and transporting chemicals. Protector wraps are vital in these applications, helping to safeguard hoses from exposure to harsh chemicals and physical damage from agricultural machinery or environmental elements.

4. Automotive and Aerospace In these high-performance fields, hoses are critical for fluid transfer, whether it’s fuel, hydraulic fluid, or coolant. The use of hose protector wraps can minimize the risk of leaks and failures, contributing to overall vehicle safety and reliability.

hose protector wrap

5. Oil and Gas The oil and gas industry involves handling highly volatile substances, and the integrity of hoses is paramount. Hose protector wraps provide an additional layer of security, reducing the risk of leaks and spills that could have catastrophic consequences.

Benefits of Using Hose Protector Wraps

1. Enhanced Durability The primary advantage of hose protector wraps is their ability to extend the lifespan of hoses. By minimizing exposure to abrasive surfaces and environmental factors, they contribute to better longevity and performance.

2. Cost Efficiency While there is an upfront cost associated with purchasing hose protector wraps, the long-term savings realized from reduced hose replacements and maintenance make them a wise investment. Industries can significantly cut costs related to downtime and repairs.

3. Safety Considerations Hoses can pose safety risks if they become damaged and fail. By using protective wraps, industries can mitigate these risks, ensuring a safer working environment for employees.

4. Improved Aesthetics In addition to protection, hose wraps can improve the overall appearance of hoses, providing a neater and more professional look to machinery and equipment.

5. Customization Options Many manufacturers offer customizable hose protector wraps that can be tailored to specific applications. This allows businesses to select the right materials and configurations that meet their unique operational needs.

Conclusion

Hose protector wraps are an essential accessory in numerous industries where hoses play a pivotal role in operations. By providing a protective barrier against physical damage and environmental factors, these wraps enhance hose durability, reduce maintenance costs, and contribute to overall safety. Investing in high-quality hose protector wraps is not just a maintenance strategy; it’s a proactive approach to ensuring operational efficiency and long-term success. As industries continue to evolve and face new challenges, the role of hose protector wraps will undoubtedly become even more significant, solidifying their place as a staple in equipment care and maintenance.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025