Hose Connector Nipple for Versatile Plumbing and Gardening Applications

Understanding Hose Connector Nipples The Essential Component in Fluid Transfer Systems

In various industries, efficient fluid transfer is crucial for operational success, whether it’s in agriculture, automotive, or plumbing systems. Among the myriad of components that facilitate this process, hose connector nipples play a vital role. These small yet significant parts provide a leak-proof connection between hoses and fittings, ensuring the smooth and safe transfer of liquids or gases.

What are Hose Connector Nipples?

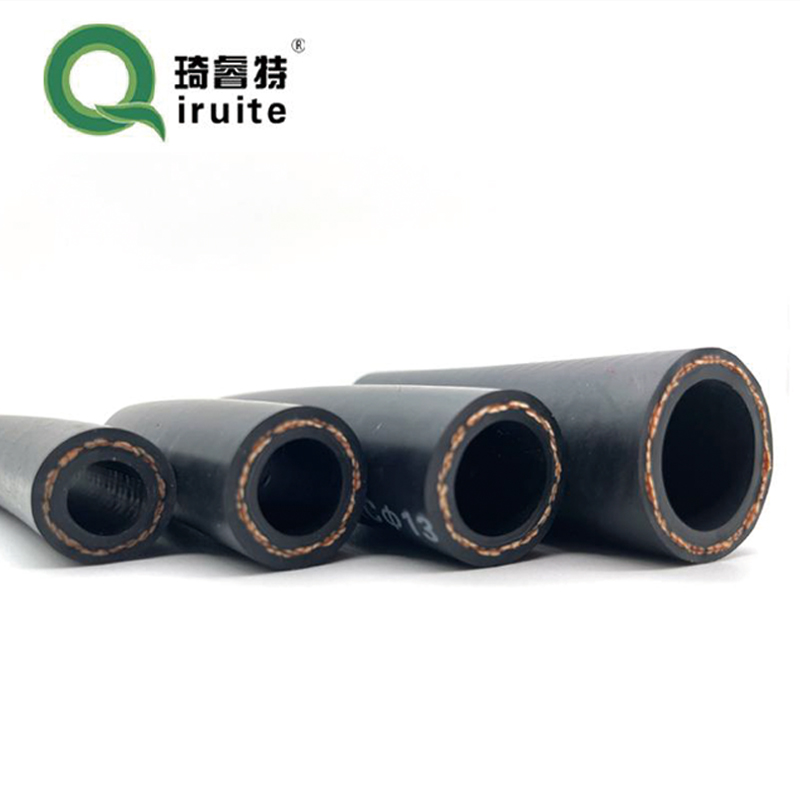

Hose connector nipples are fittings designed to connect hoses to other hoses or to valves, pumps, or other equipment. Typically made from materials like brass, stainless steel, or plastic, these nipples are engineered to resist corrosion and withstand high pressures. Their primary function is to form a tight seal that prevents leaks, which is essential for maintaining system efficiency and safety.

The design of hose connector nipples can vary significantly based on their intended use. They come in different sizes and styles, including male and female threads, barbed ends, and quick-disconnect designs. This variety ensures that they can accommodate a wide range of hose types and applications.

Key Features of Hose Connector Nipples

1. Durability A high-quality hose connector nipple is designed to withstand harsh environmental conditions, including extreme temperatures, corrosive fluids, and high-pressure situations. Materials such as stainless steel provide superior resistance to rust and wear, making them suitable for long-term use.

2. Compatibility Different industries and applications require specific types of hoses and fittings. Hose connector nipples are available in various sizes and configurations, making it easier to match them with the appropriate hoses and equipment. This compatibility helps reduce the risk of leaks and ensures a proper fit.

3. Ease of Use Many hose connector nipples are designed for quick and easy installation. Quick-disconnect features allow for speedy attachment and detachment, which is especially beneficial in situations where time is of the essence, such as in emergency repairs or maintenance.

hose connector nipple

4. Safety The importance of safety in fluid transfer cannot be overstated. Hose connector nipples are engineered to create secure connections that minimize the risk of leaks and spills. This is particularly critical in applications involving hazardous materials, where even a small leak can lead to significant safety hazards.

Applications of Hose Connector Nipples

Hose connector nipples find application across various fields, including

- Agriculture In farming, these connectors help link irrigation systems, ensuring the efficient delivery of water. They can withstand the rigors of outdoor use and can be adapted for different irrigation methods.

- Automotive In vehicles, hose connector nipples are used in cooling systems, fuel systems, and hydraulic systems. Their reliability is crucial for preventing leaks that can lead to engine overheating or fuel spills.

- Industrial Manufacturing plants often rely on hose connector nipples in fluid transfer processes. Whether it’s transporting chemicals, lubricants, or water, these connectors are essential for maintaining operational efficiency and safety.

- Plumbing In residential and commercial plumbing, hose connector nipples connect hoses to faucets or pipes. They are designed to handle various water pressures and are an essential component of any plumbing system.

Conclusion

Hose connector nipples may be small components, but their significance in fluid transfer systems cannot be understated. Their ability to provide a reliable, leak-proof connection makes them indispensable across a multitude of applications. When selecting hose connector nipples, it's essential to consider factors such as material, size, and compatibility with existing systems to ensure optimal performance. In an industry where every detail matters, choosing the right hose connector nipple could mean the difference between a successfully functioning system and potential disasters caused by leaks and failures. By understanding the importance of these connectors, professionals can make informed decisions that enhance safety, efficiency, and productivity in fluid transfer operations.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025