hose and power

Hose and Power A Vital Connection in Modern Industry

In the ever-evolving landscape of modern industry, the synergy between hoses and power dynamics plays a pivotal role in ensuring efficiency, safety, and productivity across various sectors. From manufacturing and construction to agriculture and automotive applications, hoses are crucial components that facilitate the transfer of fluids, gases, and even electrical energy, thereby amplifying power in multiple forms. Understanding the relationship between hoses and power not only highlights their importance but also emphasizes the need for careful selection, maintenance, and innovation in this field.

The Role of Hoses in Industry

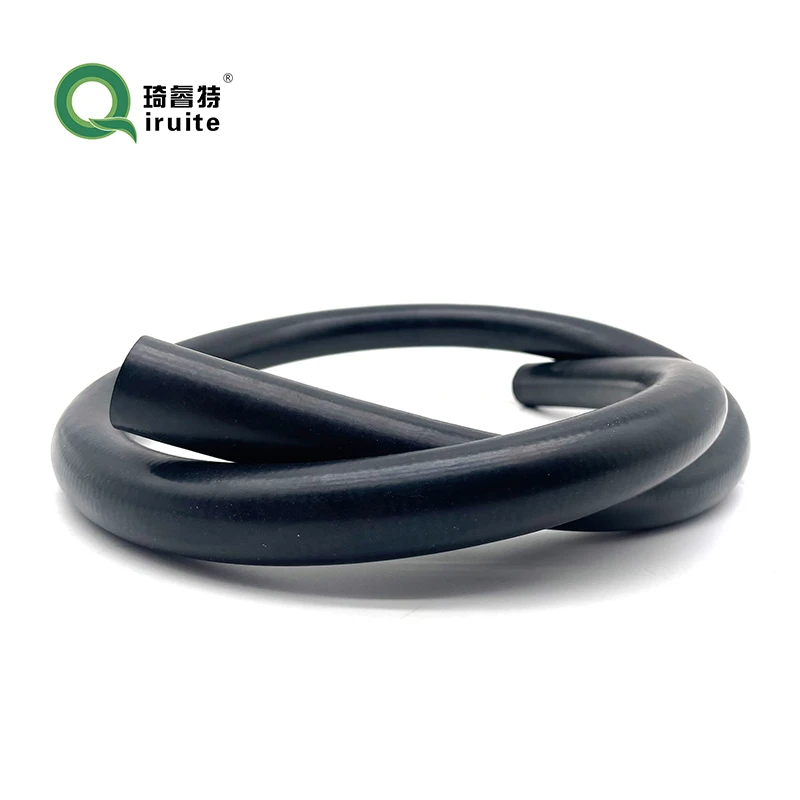

Hoses are flexible tubes designed to convey substances under pressure, including water, fuel, chemicals, and air. Their versatility is unmatched, with materials ranging from rubber and PVC to specialized composites designed to withstand high temperatures and corrosive environments. The choice of hose material significantly influences the performance and safety of the systems they support. For instance, hydraulic hoses are engineered to withstand high-pressure environments, making them essential in applications where power transmission is critical, such as in hydraulic machinery and heavy equipment.

Furthermore, the design and construction of hoses directly impact their efficiency and durability. Factors such as diameter, length, and reinforcement affect flow rates, pressure drops, and the overall energy required to move substances through the system. Therefore, the integration of hoses into power systems must be carried out with precision and foresight to ensure optimal operation.

Power Transmission and Efficiency

The connection between hoses and power becomes even more evident through the lens of efficiency. In hydraulic systems, for example, hoses are responsible for transporting hydraulic fluid from one component to another, enabling the system to perform work. Properly designed hoses can significantly reduce energy losses, thereby enhancing overall system efficiency. Conversely, using substandard hoses can lead to leaks, pressure drops, and reduced operational effectiveness, ultimately affecting productivity and increasing operational costs.

To improve power transmission, industries are innovating in hose technology. Advanced materials and designs that minimize friction, enhance flexibility, and extend lifespan are being developed. For instance, the introduction of thermoplastic hoses has revolutionized certain applications, as they provide lighter alternatives to traditional rubber hoses without compromising strength or durability. As industries seek to optimize their operations and reduce energy consumption, the role of hose technology as a facilitator of power transmission cannot be overstated.

hose and power

Safety Considerations

Alongside efficiency, the safety of hose systems is a paramount concern. High-pressure applications involve risks such as bursts or leaks, which can lead to catastrophic failures, environmental hazards, and personal injury. Ensuring the integrity of hose systems requires regular inspection, maintenance, and adherence to industry standards. Identifying wear and tear early can mitigate potential risks, preserving not only equipment but also human life.

The implementation of technology such as pressure sensors and visual inspection tools is becoming increasingly common in industries reliant on hoses for power transmission. These technologies help monitor the condition of hoses in real-time, facilitating timely maintenance and reducing the likelihood of unexpected failures.

The Future of Hoses and Power

Looking forward, the connection between hoses and power will likely continue to evolve. As industries push towards sustainability, the demand for hoses that can handle eco-friendly fluids and facilitate lower-energy operations will increase. Innovations in hose technology will focus on lighter and more durable materials that can operate efficiently under varying environmental conditions.

Moreover, with the advent of Industry 4.0, the integration of smart technologies and automation into hose systems is on the horizon. Equipped with sensors and IoT capabilities, future hoses could autonomously manage fluid and gas flows, optimize performance, and predict maintenance needs, thus intertwining the concepts of power and technology more closely than ever before.

In conclusion, the relationship between hoses and power is essential for the productivity and safety of modern industries. As we look to the future, continued advancements in hose technology will play a crucial role in enhancing performance, efficiency, and sustainability across diverse applications, ensuring that industry remains responsive to the challenges of tomorrow.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025