hose pipe screw connector

Understanding Hose Pipe Screw Connectors A Comprehensive Guide

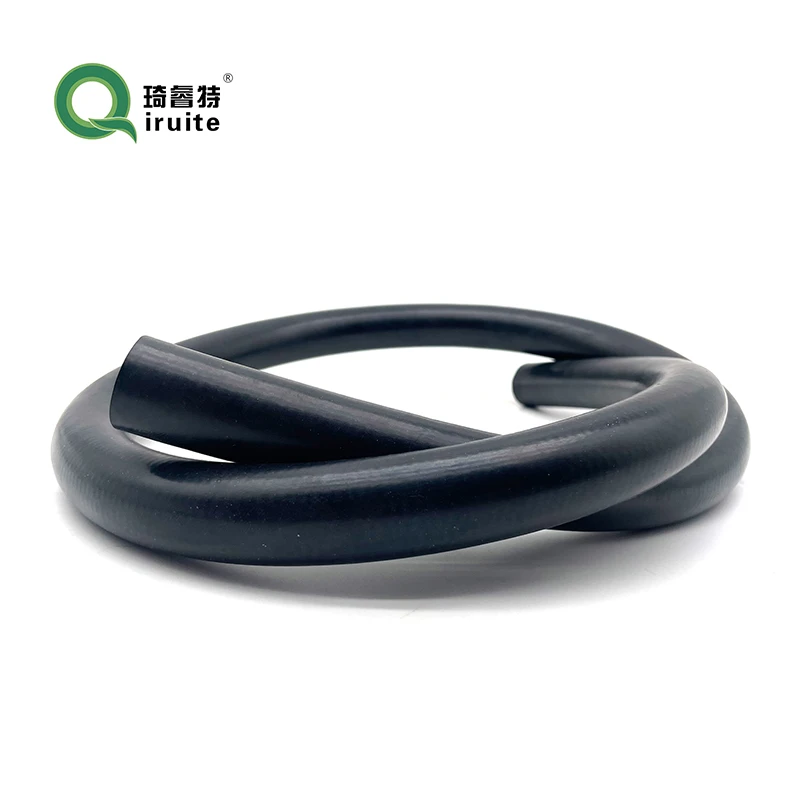

Hose pipe screw connectors are essential components in various sectors, including agriculture, construction, and automotive industries. Their primary function is to secure hoses to different fittings, ensuring a leak-proof and durable connection that facilitates the smooth flow of liquids or gases. This article delves into the significance, types, and considerations when choosing hose pipe screw connectors.

What are Hose Pipe Screw Connectors?

Hose pipe screw connectors are mechanical devices designed to connect two or more hoses or hoses to equipment securely. These connectors typically feature a threaded male or female end that allows for easy attachment and detachment. The spiral design of the screw thread ensures a tight fit, minimizing the risk of leaks, which can be critical in high-pressure applications.

Types of Hose Pipe Screw Connectors

There are several types of hose pipe screw connectors available, each suited for specific applications

1. Barbed Connectors These connectors have ridges designed to grip the inner surface of the hose tightly. They work well for low-pressure applications and are commonly used in garden hoses and aquariums.

2. Threaded Connectors Both male and female threaded connectors are widely used. These fittings are ideal for high-pressure applications and can be found in industrial settings.

3. Quick-Connectors These connectors allow for rapid attachment and detachment without the need for tools. They are commonly used in applications requiring frequent disconnections, enhancing convenience and efficiency.

hose pipe screw connector

4. Cam Lock Connectors Often employed in commercial water transfer applications, these connectors provide a quick and reliable way to connect hoses. They feature a cam lever mechanism that locks the hoses in place.

Choosing the Right Connector

When selecting hose pipe screw connectors, several factors must be considered to ensure optimal performance

1. Material Connectors are typically made from materials such as brass, stainless steel, or plastic. The choice of material should be influenced by the nature of the fluid being transported, as well as environmental factors such as temperature and exposure to chemicals.

2. Size Compatibility It is crucial to select connectors that match the diameter of the hoses being used. A mismatch can lead to leaks or hose damage.

3. Pressure Rating Each connector has a specified pressure rating. Choosing a connector that can withstand the maximum pressure of your application is essential to prevent failures.

4. Ease of Use Depending on the application, consider how easy it is to connect and disconnect the hoses. Quick-connect options may be more favorable in environments where efficiency is paramount.

Conclusion

Hose pipe screw connectors play a vital role in ensuring the effective transfer of fluids in various applications. By understanding the different types and ensuring proper selection based on material, size, pressure rating, and ease of use, users can significantly enhance the efficiency and safety of their operations. Whether for irrigation, industrial work, or automotive applications, investing in the right hose pipe screw connectors is essential for successful results.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025