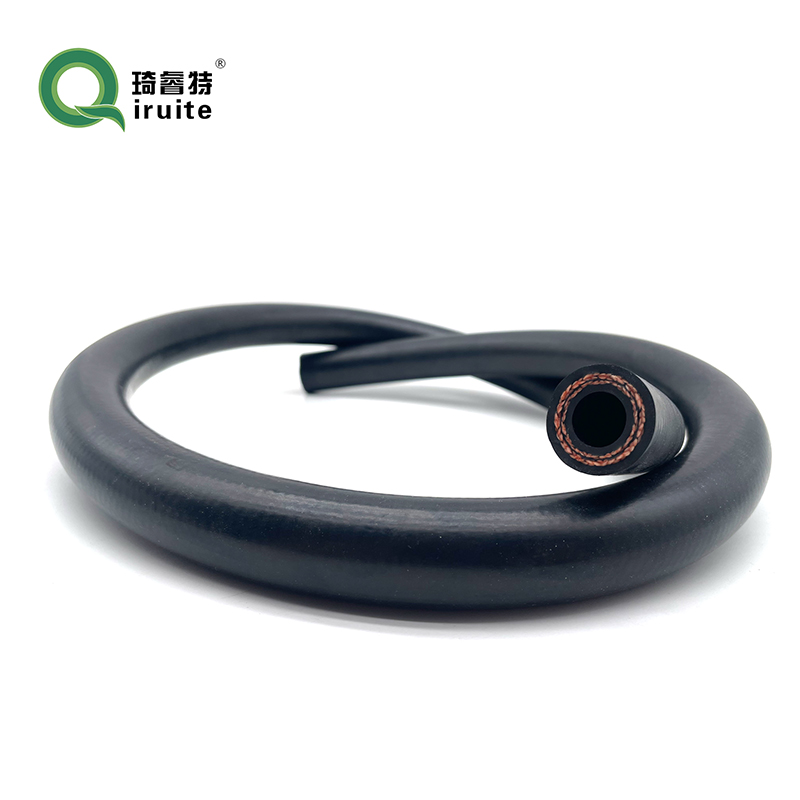

high pressure pipe coupling

Understanding High-Pressure Pipe Couplings A Comprehensive Overview

High-pressure pipe couplings are critical components in various industrial applications, particularly in sectors such as oil and gas, chemical processing, and water management. These couplings facilitate the efficient and secure connection of pipes transporting fluids at elevated pressures, ensuring the integrity and performance of piping systems. This article delves into the fundamental aspects of high-pressure pipe couplings, including their types, applications, and essential considerations for their selection and maintenance.

Types of High-Pressure Pipe Couplings

High-pressure pipe couplings come in several types, each designed to meet specific operational requirements. The most common types include

1. Threaded Couplings These couplings feature male and female threads that allow for easy assembly and disassembly. They are ideal for applications where frequent maintenance or modifications are expected. However, care must be taken to ensure proper sealing to prevent leaks.

2. Welded Couplings Welded couplings are permanently fixed to the pipe ends through welding processes, offering a robust and leak-proof connection. They are commonly used in applications where vibration and movement could compromise threaded connections.

3. Flanged Couplings Featuring raised edges around the main connection point, flanged couplings allow for easy attachment and detachment. They offer excellent mechanical strength and are especially useful in high-pressure environments.

4. Compression Couplings These couplings use a compression mechanism to join two pipe segments. They provide flexibility in joining pipes of different materials and diameters, making them an attractive option for various installations.

Applications of High-Pressure Pipe Couplings

The applications of high-pressure pipe couplings are diverse and extensive. Some notable examples include

- Oil and Gas Industry High-pressure pipe couplings are essential in drilling operations, pipeline transport, and refining processes. They ensure the safe transfer of crude oil and natural gas, which are often transported under high pressure.

high pressure pipe coupling

- Chemical Processing In chemical plants, high-pressure couplings are vital for the safe handling of corrosive and volatile substances

. These couplings must resist harsh environmental conditions and maintain leak-free connections.- Water Management In municipal water systems and wastewater treatment plants, high-pressure pipe couplings are used to transport water under great pressure. They play a crucial role in ensuring the efficient distribution of water resources.

Selecting the Right High-Pressure Pipe Couplings

Choosing the right pipe coupling is crucial for operational efficiency and safety. Factors to consider when selecting high-pressure pipe couplings include

- Material Compatibility It is essential to select couplings made from materials compatible with the fluids being transported. Common materials include stainless steel, carbon steel, and various alloys, each offering different levels of resistance to corrosion and temperature variations.

- Pressure Rating Couplings must be rated for the specific pressure conditions of the application. It’s vital to consider not only the maximum operating pressure but also any potential pressure surges.

- Temperature Resistance The selected coupling should withstand the operating temperature of its environment. High-pressure operations may involve elevated temperatures, requiring materials that can maintain integrity under stress.

- Installation Environment Consider the installation conditions such as space constraints, accessibility, and potential exposure to irregular mechanical stresses. Some couplings are better suited for tight spaces or areas exposed to high shifting or vibrations.

Conclusion

High-pressure pipe couplings are crucial components in modern industrial systems, offering reliable connections that enhance the overall safety and efficiency of fluid transport. Understanding the different types of couplings, their applications, and the factors influencing their selection can help engineers and operators make informed decisions. Proper selection, installation, and maintenance practices ensure that these couplings perform reliably throughout their service life, safeguarding against potential failures and enhancing operational integrity.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025