Feb . 08, 2025 07:16

Back to list

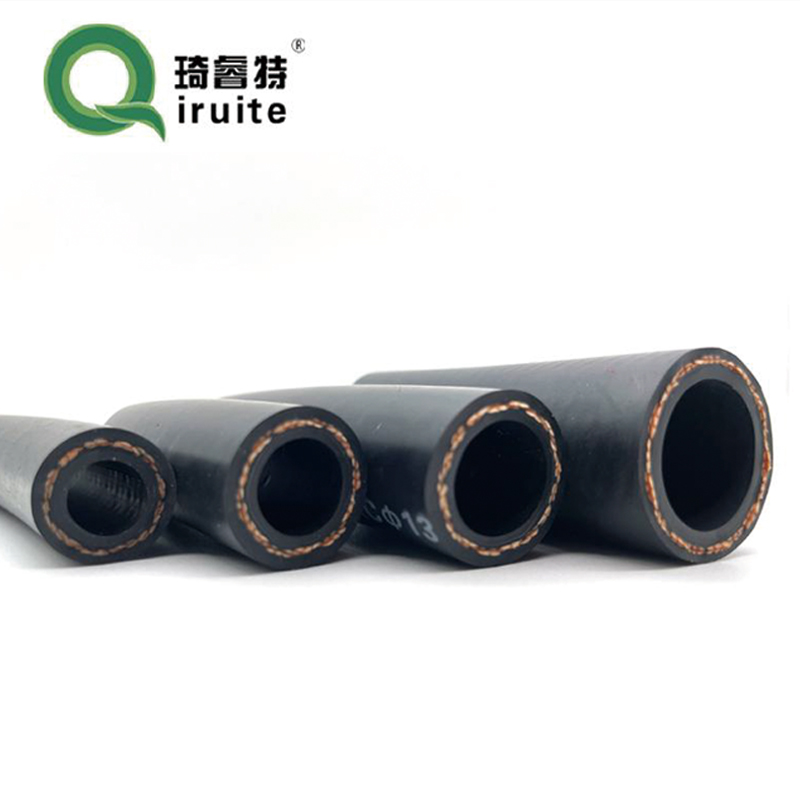

Sewer cleaning hose (sewer cleaning & jetting hose)

High pressure pipe connectors play a critical role in various industrial applications, providing a reliable solution for managing the flow of gases and liquids under extreme pressures. Their significance spans industries such as oil and gas, chemical processing, and automotive, where safety and precision are paramount.

Authoritativeness is established by brands that dominate the market through their innovative designs and dedication to quality. Industry leaders in high pressure pipe connectors often participate in setting international benchmarks for safety and efficiency, sharing their findings and contributing to new industry standards. They conduct workshops, webinars, and publish whitepapers to disseminate important information about best practices and new technologies in pipe connection solutions. Customers trust these authoritative sources because their commitment to advancing the sector ensures that they are purchasing the latest, most reliable products designed for optimal performance. Trustworthiness is paramount for components that operate under high pressure conditions. Users need to trust that the connectors will perform impeccably, as failure can lead to catastrophic consequences. Reputable manufacturers offer extensive warranties and responsive customer service to maintain the confidence of their clients. Transparency in their supply chain and manufacturing processes further builds trust. Customers have access to detailed product specifications and testing results, allowing them to make informed decisions. Furthermore, positive reviews and case studies from industries that rely on flawless high pressure systems underscore the trust placed in these connectors. In conclusion, high pressure pipe connectors are indispensable in ensuring safe and efficient operations across various high-stakes industries. Their design and production combine years of experience and expertise, backed by authoritative knowledge and established trustworthiness. As technology advances, so too do these connectors, reinforcing the safety and efficiency of high pressure systems and further solidifying their essential role across numerous applications.

Authoritativeness is established by brands that dominate the market through their innovative designs and dedication to quality. Industry leaders in high pressure pipe connectors often participate in setting international benchmarks for safety and efficiency, sharing their findings and contributing to new industry standards. They conduct workshops, webinars, and publish whitepapers to disseminate important information about best practices and new technologies in pipe connection solutions. Customers trust these authoritative sources because their commitment to advancing the sector ensures that they are purchasing the latest, most reliable products designed for optimal performance. Trustworthiness is paramount for components that operate under high pressure conditions. Users need to trust that the connectors will perform impeccably, as failure can lead to catastrophic consequences. Reputable manufacturers offer extensive warranties and responsive customer service to maintain the confidence of their clients. Transparency in their supply chain and manufacturing processes further builds trust. Customers have access to detailed product specifications and testing results, allowing them to make informed decisions. Furthermore, positive reviews and case studies from industries that rely on flawless high pressure systems underscore the trust placed in these connectors. In conclusion, high pressure pipe connectors are indispensable in ensuring safe and efficient operations across various high-stakes industries. Their design and production combine years of experience and expertise, backed by authoritative knowledge and established trustworthiness. As technology advances, so too do these connectors, reinforcing the safety and efficiency of high pressure systems and further solidifying their essential role across numerous applications.

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025