high pressure pipe connector

The Importance of High-Pressure Pipe Connectors

In various industries, the efficient and safe transport of fluids under high pressure is crucial. Whether in the oil and gas sector, chemical manufacturing, or even municipal water systems, maintaining the integrity of pipes and connectors is paramount. High-pressure pipe connectors play a vital role in ensuring the safe and efficient movement of fluids in these systems.

Understanding High-Pressure Pipe Connectors

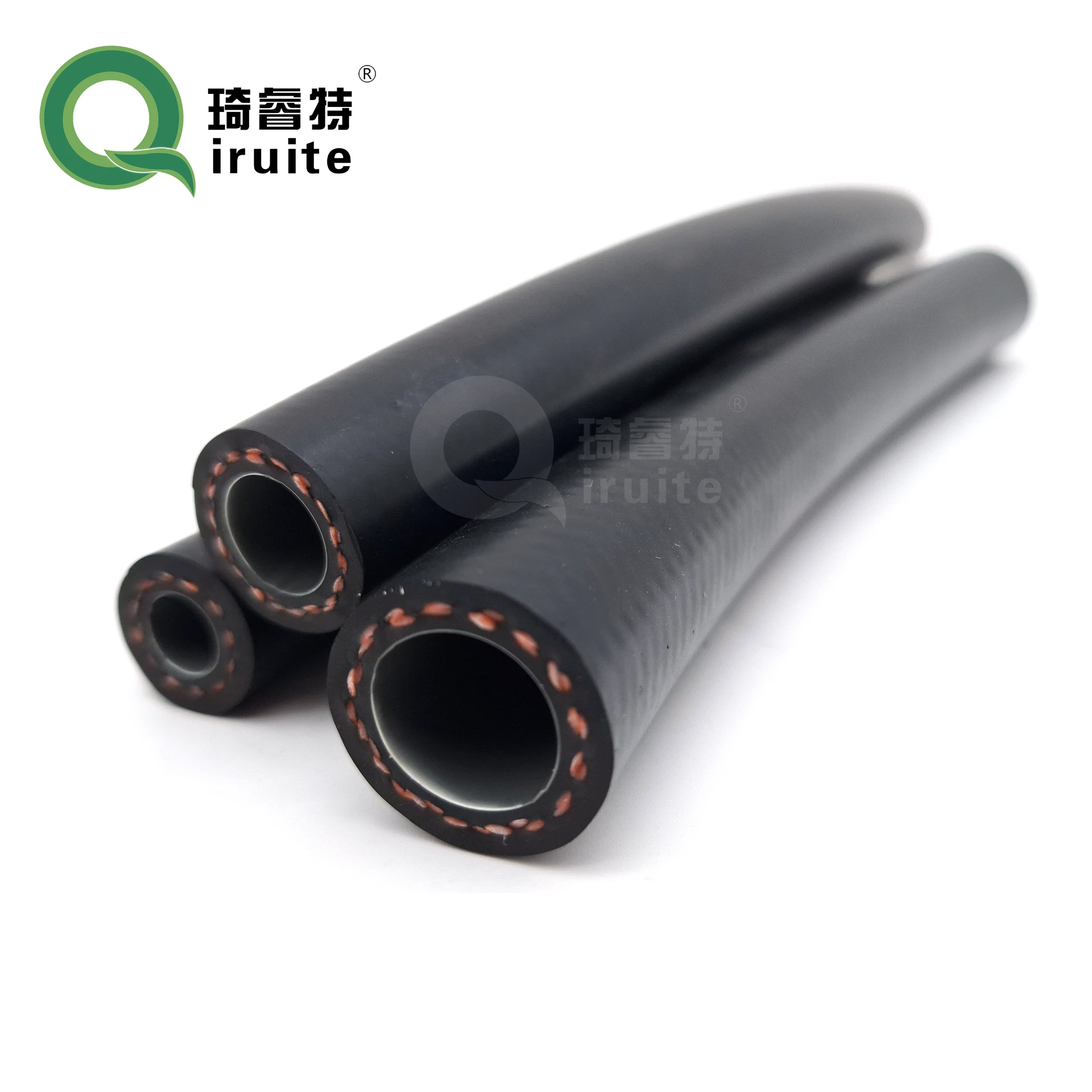

High-pressure pipe connectors are specialized fittings designed to join sections of piping that operate under significant pressure. These connectors must withstand not only the pressure of the contained fluid but also the environmental conditions surrounding the pipes, such as temperature variations and potential chemical exposure.

The connectors come in various designs, including but not limited to flanged, threaded, and welded types. Each design has its advantages and applications, depending on the specific requirements of the system.

1. Flanged Connectors These are widely used for high-pressure applications due to their strength and ability to create tight seals. Flanged connectors consist of pairs of flat surfaces with bolt holes that allow for secure fastening. They provide a good balance between ease of assembly and maintenance, making them a popular choice for pipelines that may require periodic inspection or modifications.

2. Threaded Connectors Threaded fittings involve screwing components together, which can be done quickly and efficiently. While they are easy to install, their use is generally limited to lower-pressure applications compared to flanged connectors. In high-pressure scenarios, special threading or additional sealing mechanisms may be necessary.

3. Welded Connectors These are among the most robust options available, as welding creates a permanent bond between pipe sections. This method is preferred when maximum resistance to pressure is required. However, it also means that maintenance or replacement tasks can be more complicated, as sections of the pipeline may need to be cut or removed entirely.

Applications in Various Industries

High-pressure pipe connectors are essential across multiple sectors

high pressure pipe connector

- Oil and Gas In the oil and gas industry, pipelines transport crude oil, natural gas, and refined products at varying pressures. Durable high-pressure connectors are vital to prevent leaks, which can have catastrophic environmental and economic consequences.

- Chemical Processing Chemical plants often deal with aggressive chemicals that can corrode standard materials

. High-pressure connectors that are resistant to corrosion and can handle complex chemical interactions are critical to safe operations.- Water Treatment and Distribution Municipal water systems need to transport water efficiently and reliably. High-pressure connectors ensure that systems can handle water pumped from deep wells or reservoirs under pressure without failure.

Safety Considerations

Safety is a paramount consideration when dealing with high-pressure systems. Connectors must be engineered to meet specific industry standards and certifications. Regular maintenance and inspections are essential to identify wear and tear that could compromise the system's integrity.

Moreover, using the correct type of connector for the job cannot be overstated. A mismatch in connector specifications (such as pressure rating and material compatibility) can lead to catastrophic failures. Thus, industry professionals must be well-versed in connector options and their appropriate applications.

Innovations and Future Trends

As technology continues to evolve, so do high-pressure pipe connectors. Innovations in materials, such as the development of advanced polymers and composite materials, promise lighter and even stronger connectors. Furthermore, the integration of smart technology, like sensors embedded in connectors, can provide real-time data on pressure, temperature, and potential leaks, leading to improved safety and efficiency.

Conclusion

High-pressure pipe connectors are vital components in various industrial systems. Their ability to handle the challenges of high-pressure environments makes them indispensable in ensuring the safety, efficiency, and reliability of fluid transport. As industries continue to evolve and demand more from their piping systems, the importance of these connectors cannot be overstated. Investing in the right materials, designs, and ongoing maintenance strategies will remain key to the future success of high-pressure applications. In this ever-changing landscape, staying informed about advancements in connector technology will allow industries to keep pace and ensure their operations run smoothly and safely.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025