high pressure hose pipe connector

High Pressure Hose Pipe Connectors Essential Components for Fluid Transfer

In various industries, the efficient transfer of fluids under high pressure is a critical operation. Whether it is for hydraulic systems, pneumatic machinery, or any application involving high-pressure fluid transfer, the quality and reliability of the components used play a significant role. One crucial component in this setup is the high pressure hose pipe connector. In this article, we will delve into the significance, types, applications, and considerations for selecting high pressure hose pipe connectors.

Understanding High Pressure Hose Pipe Connectors

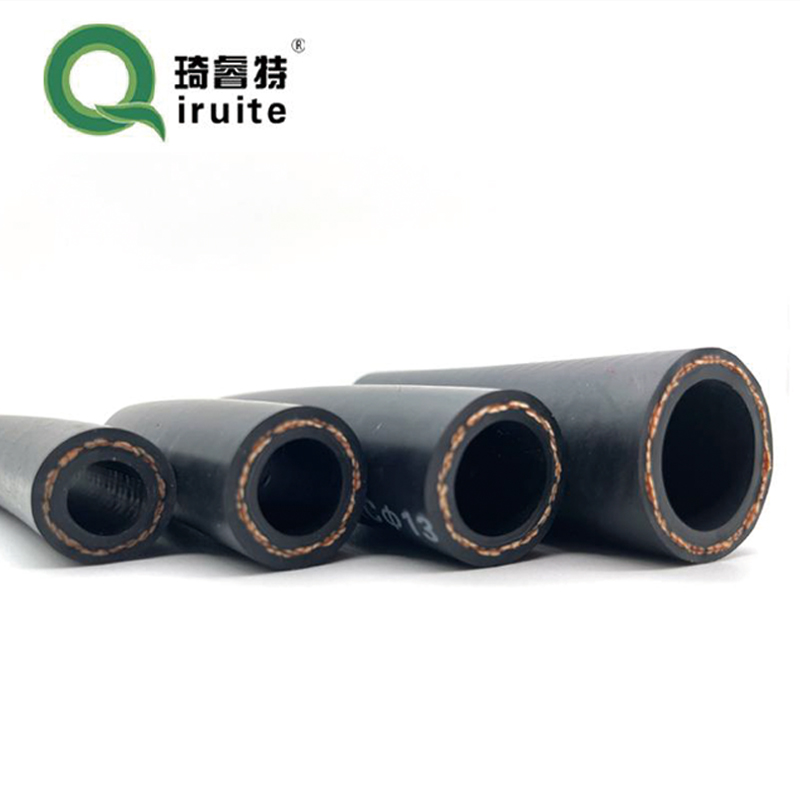

High pressure hose pipe connectors are specialized fittings designed to securely attach hoses to pipes or other hoses, ensuring a tight seal that can withstand considerable pressure. These connectors are essential in preventing leaks and maintaining the integrity of fluid transfer systems. Made from materials such as stainless steel, brass, or other robust alloys, high pressure hose pipe connectors are engineered to endure extreme conditions, including high pressures, temperatures, and corrosive environments.

Types of High Pressure Hose Pipe Connectors

1. Cam Lock Fittings These connectors allow for quick and easy attachment and detachment of hoses. They are commonly used in applications where frequent disconnecting and reconnecting is needed.

2. Threaded Connectors These offer a secure, permanent connection through threaded interfaces. They are ideal for applications requiring a high degree of pressure retention and durability.

3. Flange Connectors Used in heavy-duty applications, flange connectors provide a wide surface area for sealing, making them suitable for high pressure and high flow applications.

4. Push-to-Connect Fittings These connectors simplify the hose attachment process by allowing users to push the hose directly into the fitting, which automatically secures it in place.

5. Barbed Connectors Barbed connectors feature protruding ridges that grip the hose, ensuring a tight fit. They are popular in applications where flexibility and movement are necessary.

Applications of High Pressure Hose Pipe Connectors

High pressure hose pipe connectors are utilized in numerous industries, including

- Hydraulics Used in machinery, construction equipment, and automotive applications for transferring hydraulic fluid under high pressure. - Pneumatics Essential in systems that utilize compressed air, such as factories and assembly lines.

high pressure hose pipe connector

- Oil and Gas Critical for transporting oil, gas, and other fluids at high pressures during extraction and processing

.- Chemical Processing Employed in situations involving corrosive substances where durable connectors can prevent leaks.

- Agriculture Used in irrigation systems and equipment that require reliable fluid transfer.

Considerations for Selecting High Pressure Hose Pipe Connectors

When selecting high pressure hose pipe connectors, several factors must be considered to ensure optimal performance

1. Material Compatibility The material of the connector should be compatible with the fluids being transferred. For instance, corrosive substances may require special alloys or coatings.

2. Pressure Rating Each connector comes with a specified pressure rating, denoting the maximum pressure it can handle. Selecting a connector with an appropriate pressure rating for your application is crucial.

3. Temperature Resistance High pressure systems can generate significant heat. Ensure that the connectors you choose can withstand the operating temperature of your application.

4. Size and Dimensions Proper sizing is essential for preventing flow restrictions or leaks. Measure the specific diameter and length requirements of your hoses and pipes.

5. Ease of Installation Depending on the application, certain types of connectors may offer ease of installation and maintenance. Quick connect options, for instance, save time in setups that require frequent disassembly.

6. Regulatory Compliance Ensure that the selected connectors meet relevant industry standards and regulations, especially in sensitive applications like food processing or healthcare.

Conclusion

High pressure hose pipe connectors are integral components in a wide array of industries that rely on the efficient and safe transfer of fluids under pressure. With various types available and specific considerations to take into account, choosing the right connector is essential for optimizing performance and ensuring safety. The right high pressure hose pipe connector not only enhances operational efficiency but also minimizes downtime caused by leaks or equipment failure. As industries continue to innovate, the importance of reliable connectors will only grow, emphasizing the need for quality components in high-pressure applications.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025