Gi Coupling Pricing Trends and Analysis for 2023

Understanding GI Coupling Prices An Essential Guide for Industrial Applications

In the world of industrial connections, GI (Galvanized Iron) couplings play a pivotal role in various applications, ranging from construction to plumbing. As industries expand and evolve, the demand for reliable and cost-effective solutions becomes increasingly paramount. This article delves into the intricacies of GI coupling prices, providing valuable insights into how pricing is determined and what factors influence the market.

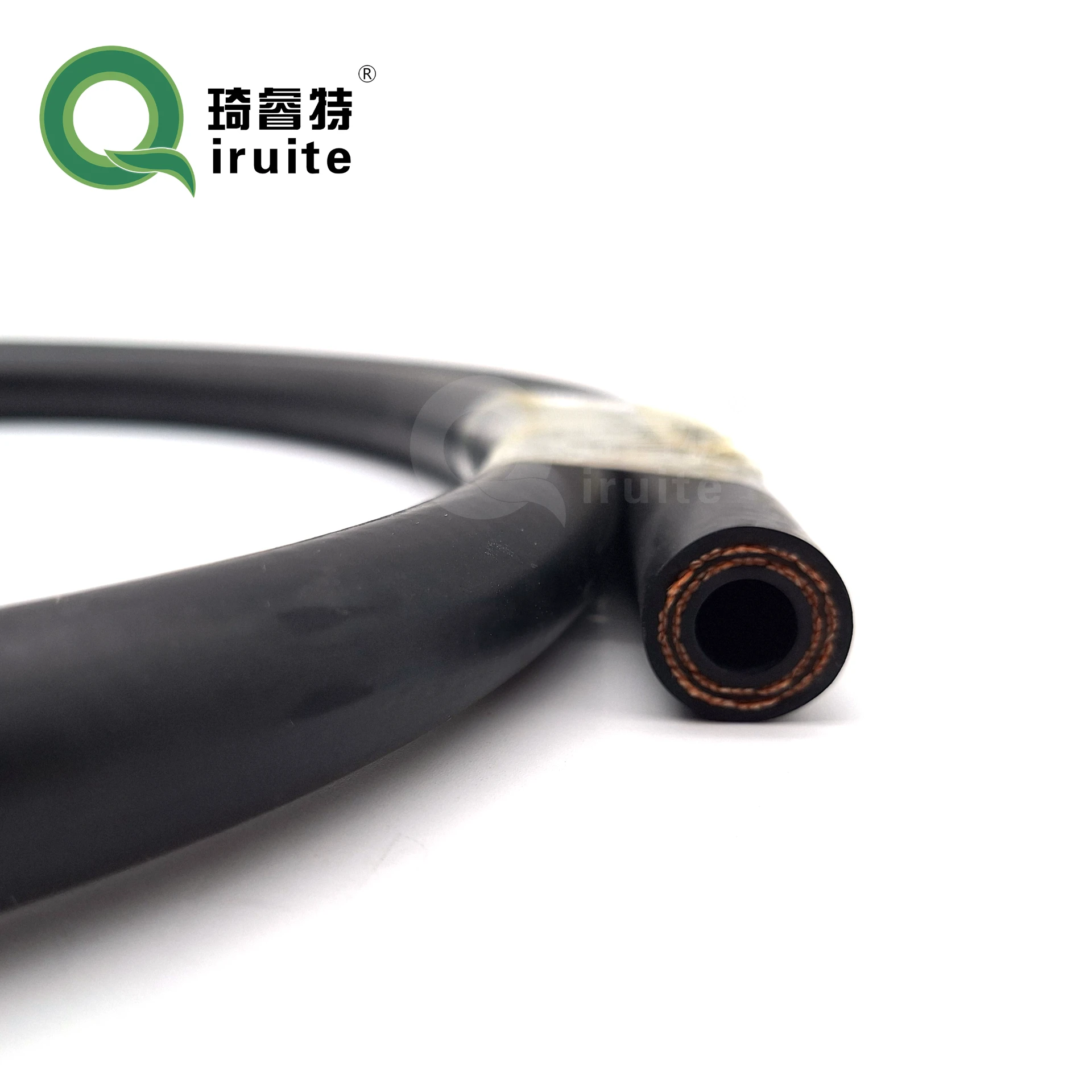

What are GI Couplings?

GI couplings are fittings made from galvanized iron, which is coated with a layer of zinc to enhance its resistance to corrosion. These couplings are widely used to connect pipes and tubes, ensuring a secure and leak-proof joint. Their durability and strength make them a preferred choice for a variety of settings, including water supply systems, irrigation, and even for supporting structural elements in buildings.

Factors Influencing GI Coupling Prices

1. Material Quality The quality of the galvanized iron used in manufacturing GI couplings significantly impacts their price. Higher quality materials that offer better corrosion resistance and longer lifespan tend to be more expensive. Businesses are often willing to pay a premium for products that promise durability and reliability.

2. Size and Specification GI couplings come in various sizes and specifications, tailored to suit different applications. Larger or specialized couplings often require more material and precision engineering, leading to higher costs. Therefore, the size and type of coupling needed will play a critical role in pricing.

gi coupling price

3. Manufacturing Process The method of production also influences the cost of GI couplings. Advanced manufacturing techniques that ensure high precision and consistency may raise production costs, which manufacturers pass on to consumers. Conversely, lower-cost production methods may result in lower prices but can compromise quality.

4. Market Demand The demand for GI couplings can fluctuate based on market trends and seasonal projects. During peak seasons, when construction and industrial activities surge, prices may increase due to high demand and limited supply. Conversely, in off-peak seasons, prices may stabilize or decrease.

5. Supplier and Distribution Costs The source of purchase also affects pricing. Different suppliers may have varied pricing policies based on their purchasing power, distribution networks, and logistics costs. Additionally, local availability can impact pricing, as suppliers may charge more for delivery.

6. Economic Factors Broader economic trends, such as inflation, raw material costs, and currency fluctuations, impact the pricing of GI couplings. Changes in steel prices, in particular, can lead to significant variations in coupling prices, as galvanized iron is primarily made from steel.

Conclusion

Understanding GI coupling prices is essential for industries that rely on these components for their operations. By considering the factors outlined above, manufacturers and purchasers can make informed decisions that align with their budget and quality expectations. As the market for GI couplings evolves, staying abreast of pricing trends and supplier options will aid businesses in achieving cost efficiencies while ensuring the durability and reliability of their infrastructure. Whether for a large-scale project or a small repair, knowing what influences prices will help stakeholders navigate the market effectively.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025