Ford 555 Backhoe Power Steering Hose Schematic Overview and Installation Guide

Understanding the Ford 555 Backhoe Power Steering Hose Diagram

The Ford 555 backhoe is a versatile piece of heavy machinery that has been widely used in construction, agriculture, and various other industries since its introduction. One of the critical systems in the Ford 555 backhoe is the power steering system, which allows for easier maneuverability and control of the machine. A crucial component of this system is the power steering hose, which must be correctly installed and maintained to ensure optimal performance. In this article, we will explore the importance of the power steering hose, details regarding the Ford 555 backhoe power steering hose diagram, and tips for maintenance.

Importance of the Power Steering System

A power steering system significantly reduces the amount of effort required to steer a large piece of equipment like the Ford 555 backhoe. By using hydraulic fluid, the system amplifies the steering effort, allowing operators to make precise movements with minimal physical exertion. If the power steering hose is damaged or leaking, it can lead to a loss of fluid, resulting in reduced steering efficiency or complete steering failure. Therefore, understanding the components—particularly the hoses—in the power steering system is vital for operators and mechanics alike.

Overview of the Power Steering Hose Diagram

The power steering hose diagram for the Ford 555 backhoe serves as a visual reference that illustrates the layout and connections of the power steering system. It typically includes

1. Reservoir This is where the hydraulic fluid is stored. The power steering hose connects the reservoir to the pump, allowing for fluid flow.

2. Pump The pump pressurizes the hydraulic fluid, sending it through the system. The diagram will show how the pump connects to the hoses leading to the steering gear.

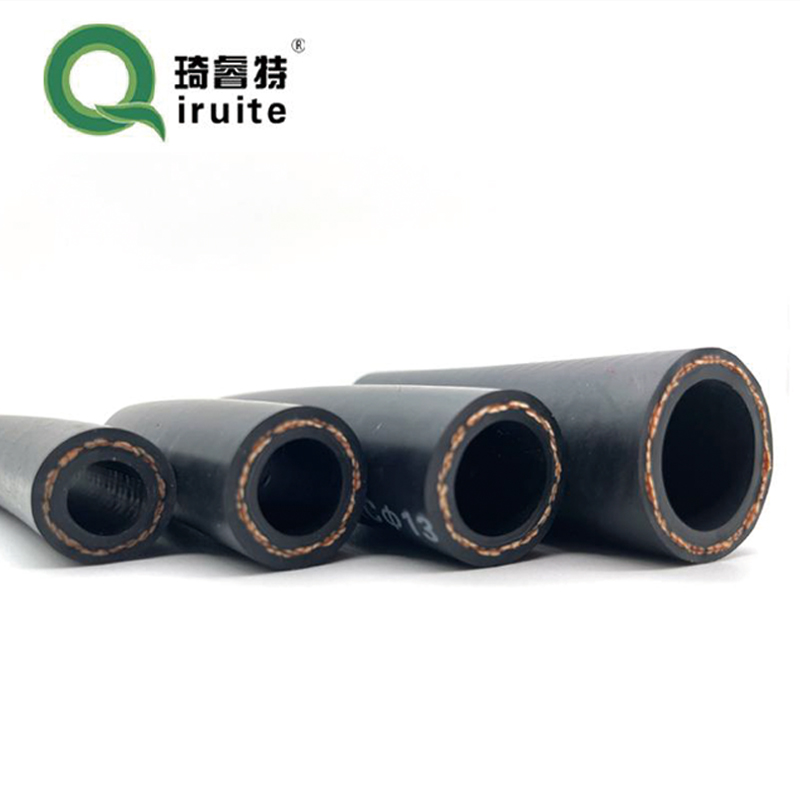

3. Hoses The power steering hoses are crucial in directing the hydraulic fluid throughout the system. The diagram indicates the high-pressure and return hoses, showcasing how fluid flows under pressure from the pump to the steering gear and back to the reservoir.

4. Steering Gear This component is where the operator's steering input is translated into steering movement. The diagram provides a clear path of how the hydraulic fluid interacts with the steering gear to enable smooth movements.

ford 555 backhoe power steering hose diagram

5. Connections and Fittings The diagram also includes specifics about different types of fittings and connections. Proper connections are essential to prevent leaks and ensure system integrity.

Steps for Maintenance and Troubleshooting

To ensure the longevity and efficiency of the power steering system, regular maintenance and inspection of the hoses are necessary. Here are some key steps

1. Visual Inspection Regularly check hoses for any signs of wear, cracking, or leaks. The power steering hoses are exposed to high pressures, making them prone to wear over time.

2. Hydraulic Fluid Levels Keep an eye on the fluid levels in the reservoir. A drop in fluid levels could indicate a leak in the hoses.

3. Connections Ensure that all connections and fittings are secure. Loose connections can lead to leaks and decreased system performance.

4. Replace Damaged Hoses If any hoses appear damaged or compromised, they should be replaced immediately. It's advisable to use OEM (Original Equipment Manufacturer) hoses for proper fitting and performance.

5. Consult the Diagram Use the power steering hose diagram as a guide whenever you're performing checks or repairs. It provides a clear layout of how everything is connected and can help you identify potential problems.

Conclusion

Understanding the Ford 555 backhoe power steering hose diagram is essential for anyone working with this machinery. The power steering system is vital for effective operation and maneuverability. Regular maintenance and a clear understanding of each component’s function within the system are crucial for preventing breakdowns and ensuring that the machine runs smoothly. By paying attention to the power steering hoses, operators can keep their Ford 555 backhoe in excellent working condition, maximizing productivity and efficiency on the job site.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025