Flexible Hose Connector for Easy Attachment to Any Standard Pipe System

Understanding Hose Pipe End Connectors A Comprehensive Guide

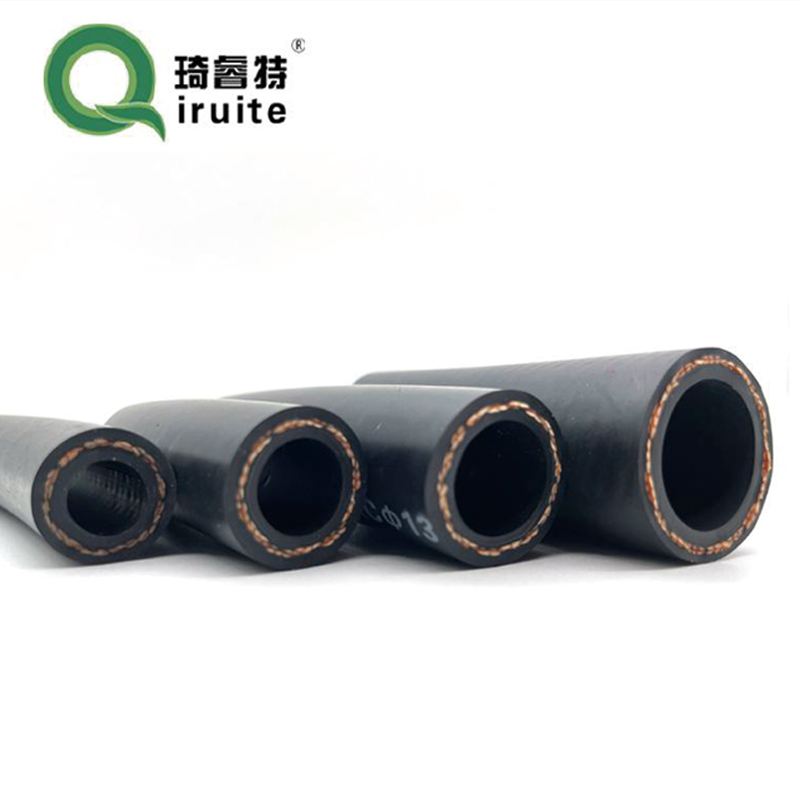

Hose pipe end connectors are essential components in a variety of applications, ranging from gardening to industrial settings. These connectors serve as the link between hoses and various devices or systems, ensuring that fluid, air, or gas can be transferred efficiently and effectively. This article aims to provide a thorough understanding of hose pipe end connectors, including their types, applications, benefits, and tips for choosing the right connector for your needs.

Types of Hose Pipe End Connectors

Hose pipe end connectors come in various shapes and sizes, designed to fit specific hose diameters and connection types. The most common types include

1. Barbed Connectors These connectors feature ridges that grip the interior of the hose, securing a tight fit. They are usually made from plastic or metal and are popular in both garden and industrial applications.

2. Threaded Connectors These connectors screw onto the hose and are available in different thread sizes and types (such as NPT or BSP). They provide robust connections and are ideal for high-pressure situations.

3. Quick Connect/Disconnect (QCDC) Connectors These connectors allow for easy attachment and detachment of hoses without the need for tools. They are widely used in situations where hoses need to be frequently connected and disconnected, such as in pressure washers or air compressors.

4. Cam Lock Connectors Often used in industrial applications, these connectors feature a lever that locks the hose in place. They are especially useful for transferring liquid or bulk materials.

5. Swivel Connectors These connectors allow for rotation to prevent tangling of hoses. They are especially useful in applications where the hose needs to move around freely without kinking.

Applications of Hose Pipe End Connectors

The applications of hose pipe end connectors are vast and varied. In gardening, barbed or threaded connectors are often used to connect hoses to watering systems and sprinklers. In industrial settings, quick-connect and cam lock connectors are utilized for moving liquids between tanks and machinery. Additionally, these connectors play a critical role in automotive applications, where they secure fuel or coolant hoses.

In agricultural environments, hose pipe end connectors are crucial for irrigation systems, ensuring that water is delivered efficiently to crops. Furthermore, their usage extends to the construction industry, where they are used to connect hoses for pneumatic or hydraulic equipment.

hose pipe end connector

Benefits of Using Hose Pipe End Connectors

Hose pipe end connectors offer several benefits, including

- Ease of Use Many connectors are designed for quick attachment and detachment, reducing the time needed for setup or adjustments.

- Versatility With various types and sizes available, these connectors can suit virtually any application.

- Durability High-quality connectors are made to withstand pressure and are resistant to corrosion, ensuring longevity in both domestic and industrial uses.

- Leak Prevention Properly fitted connectors minimize the risk of leaks, which can save resources and reduce environmental impact.

Choosing the Right Hose Pipe End Connector

Selecting the right hose pipe end connector involves considering several factors

- Compatibility Ensure that the connector matches the hose's diameter and type, as well as the device or system it will connect to.

- Material Depending on the application, choose materials that can withstand the conditions (e.g., temperature, pressure, or corrosive substances).

- Connection Type Determine if a barbed, threaded, or quick-connect solution is most suitable for your needs.

In conclusion, hose pipe end connectors are vital elements in many systems, significantly impacting the efficiency and effectiveness of fluid transfer. By understanding the types available, their applications, and how to choose the right one, you can ensure optimal performance in any project or application involving hoses.

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025