flanged flexible pipe coupling

Understanding Flanged Flexible Pipe Couplings

Flanged flexible pipe couplings are essential components in various piping systems used in industries such as oil and gas, water treatment, pharmaceuticals, and chemicals. These couplings provide a secure connection between two pipe sections while allowing for flexibility and motion. Their design helps accommodate misalignments, vibrations, and thermal expansions, thus ensuring the integrity and longevity of piping systems.

What Is a Flanged Flexible Pipe Coupling?

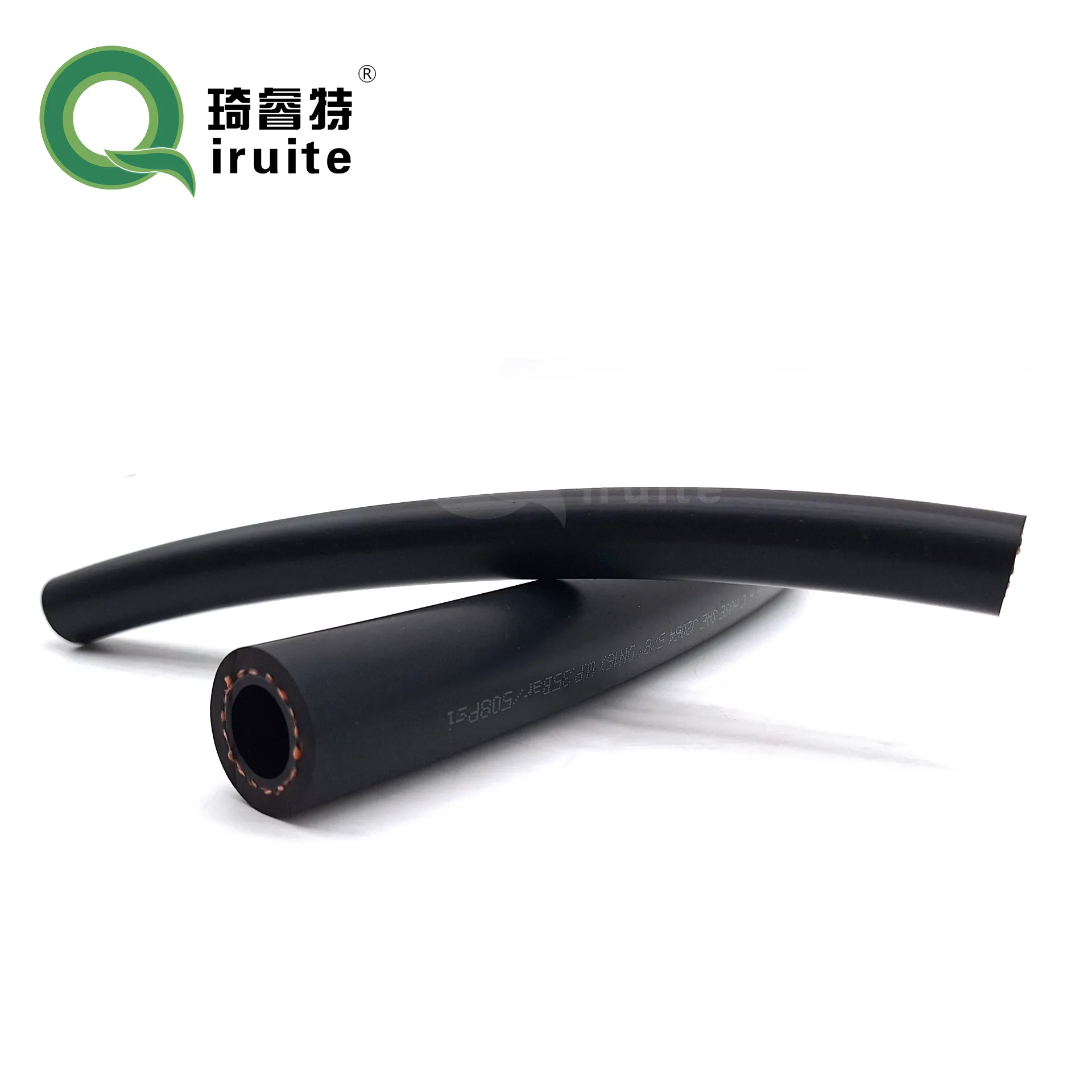

A flanged flexible pipe coupling typically consists of two flanges, a flexible sleeve, and sometimes additional components like gaskets and bolts. The flanges are bolted to the ends of two adjoining pipes, allowing for a tight and secure connection. The flexible sleeve, usually made from elastomers or rubber, provides the necessary flexibility to absorb movements caused by thermal expansion or external vibrations.

The flexible nature of these couplings is vital in preventing stress on the pipes and the attached plumbing fixtures. Because pipes are often subject to various forces such as ground movement, temperature variations, and pressurized flow, a rigid connection could lead to leaks, fractures, or even catastrophic failures.

Benefits of Flanged Flexible Pipe Couplings

1. Ease of Installation Flanged flexible couplings simplify the installation process. The pre-drilled holes on the flanges allow for straightforward alignment and fastening. This feature eliminates the need for complex alignment tools and reduces the time required for installation.

2. Vibration Dampening In many industrial applications, equipment generates vibrations that can be transmitted through connected piping. The flexible sleeve acts as a dampening agent, minimizing the transfer of vibrations and protecting connected equipment from potential damage.

3. Thermal Expansion Compensation Temperature fluctuations can cause pipes to expand and contract. A flanged flexible coupling can accommodate such movements, preventing undue stress on the piping system. This capability is particularly important in applications where temperature variations are significant, such as in steam or hot water pipelines.

4. Misalignment Handling Installation errors or ground movement can lead to misalignment of pipes. Flanged flexible couplings can adjust to these misalignments, ensuring a proper seal and preventing leaks.

flanged flexible pipe coupling

5. Reduced Maintenance Costs By preventing leaks and minimizing the risk of pipe damage, flanged flexible pipe couplings can result in lower maintenance costs over the life of the system. They help in prolonging the lifespan of the piping infrastructure, which is an essential aspect of cost-efficiency in any industrial operation.

Applications of Flanged Flexible Pipe Couplings

Flanged flexible couplings are widely used across a range of applications

- Water and Sewage Management In municipal water and sewage systems, these couplings help in connecting various types of pipes, accommodating ground shifts and changes in temperature.

- Oil and Gas Industry The oil and gas sector frequently utilizes flanged flexible couplings to connect pipelines that transport crude oil, natural gas, and other fluids under varying pressure and temperature conditions.

- HVAC Systems In heating, ventilation, and air conditioning systems, these couplings are employed to connect ductwork and piping while allowing for movement and expansion.

- Chemical Processing Chemical plants rely on flanged flexible pipe couplings for safely transporting aggressive chemicals, accommodating both thermal expansions and vibrations without compromising the integrity of the system.

Conclusion

In summary, flanged flexible pipe couplings are a fundamental aspect of modern piping systems, providing critical benefits that enhance both performance and longevity. Their unique ability to accommodate flexure, reduce vibrations, and mitigate the effects of thermal expansion makes them invaluable in various industries. When properly selected and installed, these couplings contribute significantly to the overall efficiency and reliability of fluid transport systems, ultimately leading to safer operations and reduced maintenance costs. As industries continue to evolve, the demand for reliable flexible connections in piping systems will only increase, highlighting the importance of understanding and implementing flanged flexible pipe couplings.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025